Bodor Tech Blog

Trending and helpful laser knowledge for your success

Understanding Laser Power - How Do I Choose Power For Metal Cutting?

The market for laser cutting machines has experienced considerable growth in parallel to the increased demand for laser cutting. Selecting the right laser power is crucial for businesses to optimize their productivity, quality, and return on investment.

In general, lasers with power levels greater than 6kW are considered to be high power, while machines with a power level ranging from 3kW to 6kW are categorized as middle power. Low power level is defined for machines with less than 3kW.

The following factors might influence your power selection:

Material thicknesses - The power level of a laser machine is directly proportional to the thickness of the metal it can process. The thicker the metal, the more power is required to cut.

Metals - Higher laser power is more effective when cutting high-reflective metals, as it enables the laser beam to operate more smoothly without being affected by back-reflection.

Operating efficiency - As the power increases, the number of units produced per hour increases. Machines with high power levels achieve fast cutting speeds and carry out direction changes quickly so as not to restrict productivity, improving operating efficiency.

Price - While high kW offers certain advantages, investing in a machine with higher power increases operating costs and does not necessarily equate to better processing capacities.

Q&A section (the following text will be using ‘carbon steel’ for the example)

How do I seek the balance between processing performance and costs?

To begin with, it is important to determine your budget for equipment and the range of cutting thicknesses you will be working with. In general, common material thicknesses are 6mm, 8mm, 12mm, 25mm, 40mm, and thicknesses exceeding 40mm.

If you handle materials ranging from 6mm to 12mm thick, we can consider two aspects, cutting quality and efficiency. If you have a limited budget but desire high standards of precision, then a 3kW machine would suffice for your requirements. Such machines offer great performance for cutting carbon steel sheets that are less than 8mm in thickness. The cross-section exhibits a mirror finish, enabling a maximum cut thickness of up to 20 millimeters at 0.3 to 0.5 meters per minute. The 3kW device can cut thick plates and also maintain good cutting performance for medium and thin sheets.

What power level would you recommend for a versatile machine investment, considering that my budget is not constrained?

If you have a relatively ample budget, a 6kW laser cutting machine could be a great option for you. When paired with scanning cut technology, this 6kW machine can significantly increase both the processing range and speed of carbon steel cutting with air. It would be perfect for processing carbon steel plates within the range of 12mm at speeds of 2.5 to 5.2 meters per minute, while also reducing costs. Additionally, the 6kW machine consistently produces results because it can process carbon steel plates up to 20mm thick at speeds of 0.5 to 0.8 meters per minute, making it suitable for both medium to thin plates and thick plates.

What would be the best scenario for high-power lasers, specifically over 10kW?

Let’s also approach this from the aspects of cutting quality and efficiency. To achieve high-quality cutting with moderate efficiency, in terms of 25mm thick carbon steel plates, a 12kW laser cutting machine would be sufficient. This is because a 12kW laser using oxygen can achieve bright-cut finishes when cutting carbon steel within the range of 25mm (at speeds of 0.5 to 1.2 meters per minute), demonstrating excellent surface smoothness and taper (with taper angle maintained within 20mm). However, when cutting 40mm thick plates at speeds of 0.5 to 0.9 meters per minute, the cross-section produced by a 12kW system will be of a matte finish, and its efficiency for such tasks will be lower.

If you are looking for a laser cutting machine that can deliver high processing efficiency without compromising on quality, you can turn to a 24kW laser system. With air cutting capabilities, this machine allows you to cut through thicker carbon steel sheets of up to 25mm thick plates with faster speeds ranging from 1.2 to 2.9 m/min. This is double the speed of oxygen cutting, and it ensures maximum efficiency for your needs. The 24kW system also performs steadily when cutting 40mm thick plates, making it an ideal choice for completing big batches of cutting with consistent results.

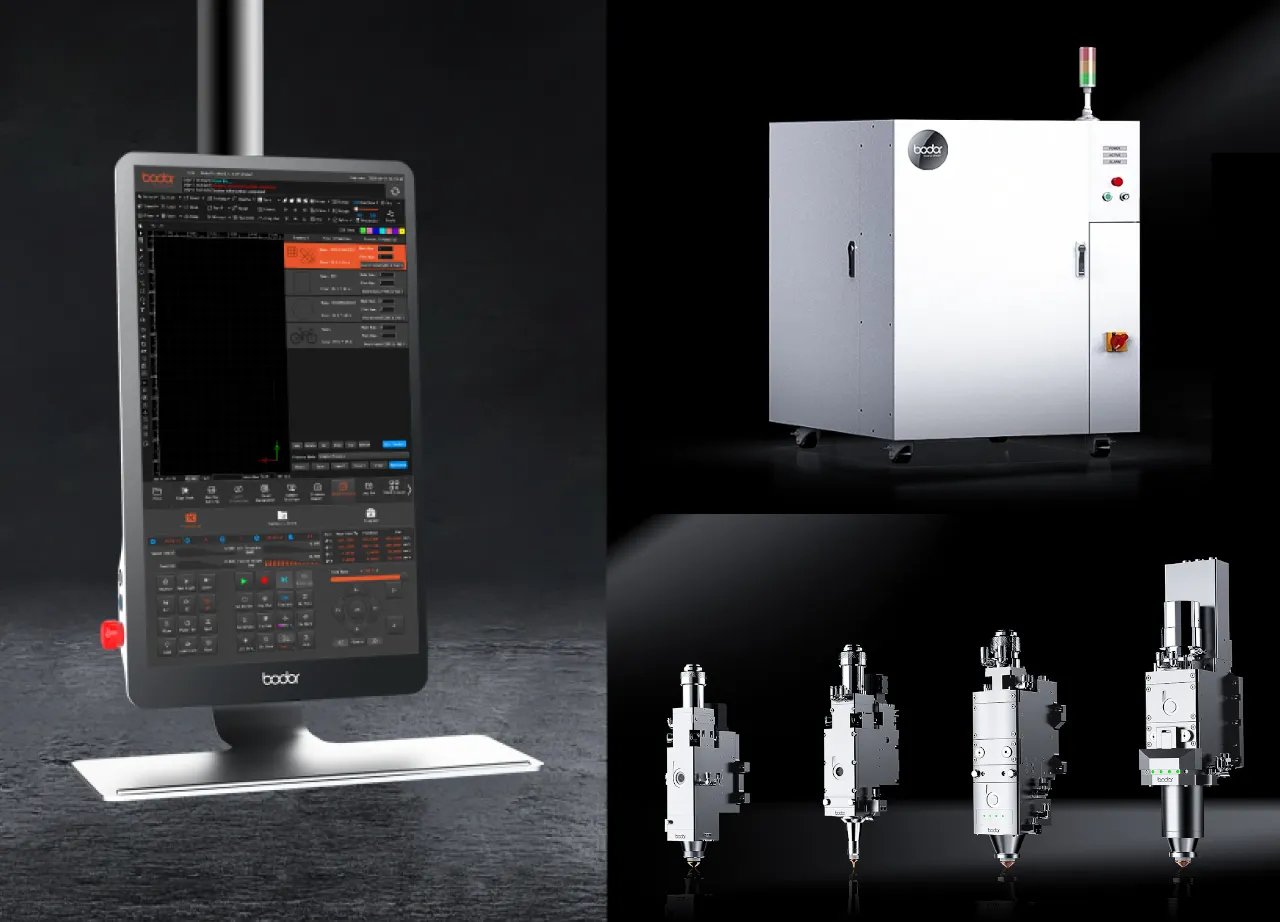

As a top provider of laser technology and solutions, Bodor offers a wide selection of products with various power levels to choose from. More importantly, the sales team can assist you in analyzing your production needs to determine the ideal power level that boosts productivity for your specific projects. Make sure you contact us before making a purchase.