Advancing cutting of building materials with Bodor fiber laser machines

Discover why traditional cutting methods like mechanical saws, plasma, and flame cutting fall behind in precision, efficiency, and flexibility. Learn how Bodor Laser’s fiber laser cutting machines offer unmatched precision, speed, and versatility for building materials like steel, aluminum, and more, helping manufacturers reduce waste and boost productivity!

Cici

Feb 11, 2025Precision, Speed, Versatility—Cut Smarter with Bodor Laser!

Why Traditional Cutting Methods Fall Behind

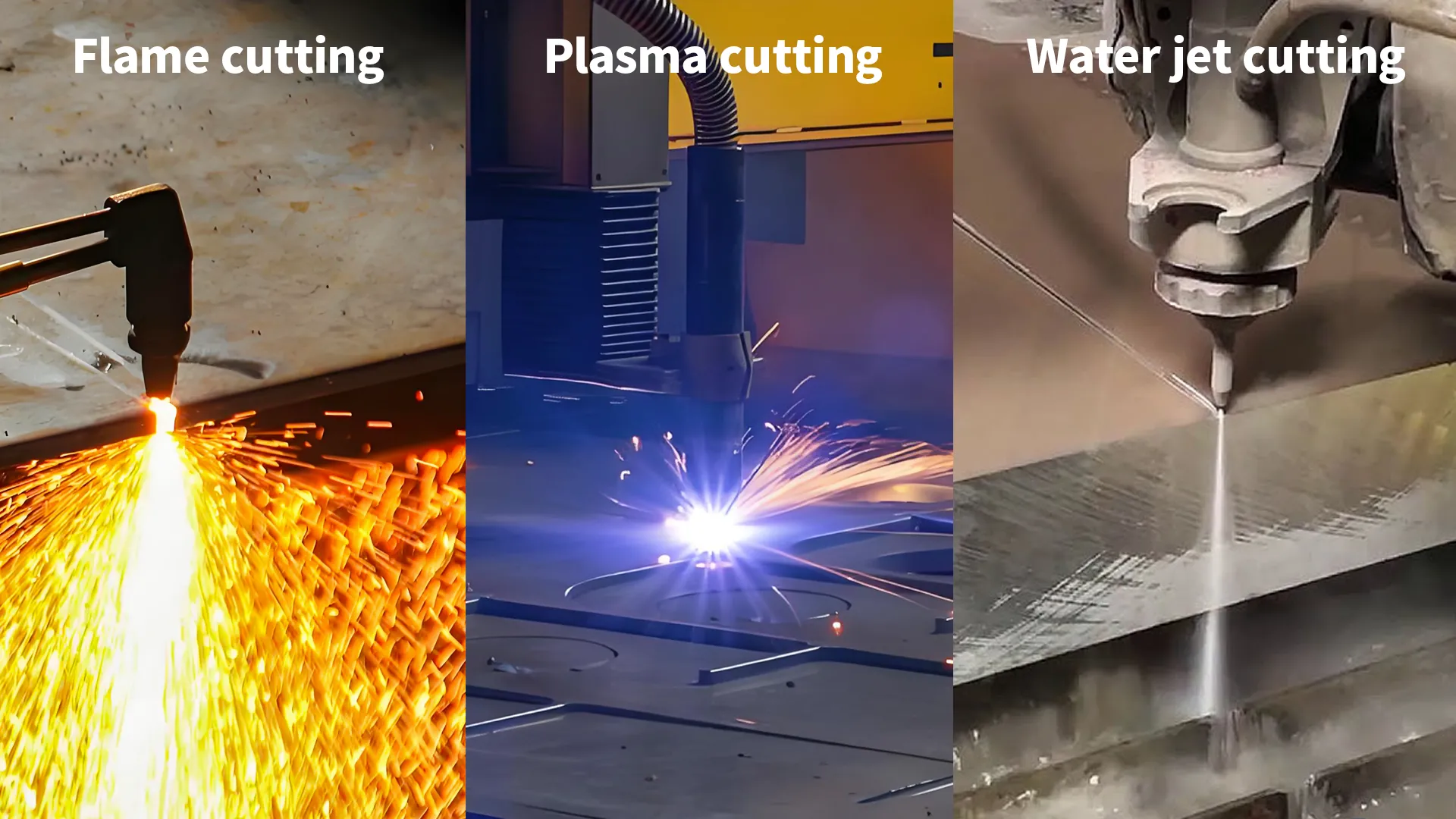

For years, traditional cutting methods like mechanical saws, plasma cutting, water jet cutting, and flame cutting have been used to process building materials like steel and aluminum. However, these methods now face several significant drawbacks:

- Low Precision: Mechanical saws and flame cutting struggle to achieve the accuracy required for intricate or custom designs, often leading to rough or inconsistent cuts.

- High Material Waste: Traditional methods such as plasma cutting and water jet cutting, while effective for certain tasks, can result in significant material waste due to less precise cutting and larger kerf widths. This drives up costs for manufacturers.

- Limited Flexibility: Mechanical saws, in particular, lack the ability to accommodate design changes mid-production. Adjusting or reconfiguring parts can be costly and time-consuming compared to traditional methods.

- Slow Production Times: When processing thick materials like steel, methods such as flame cutting and water jets are often too slow to meet tight production schedules, especially when large volumes are required.

How Does Bodor Laser Technology Solve These Issues?

Bodor ' s fiber laser cutting machines provide advanced solutions that overcome these challenges:

Unmatched Precision: Fiber lasers allow for clean, precise cuts, reducing the need for secondary finishing processes. This is particularly important in creating intricate patterns or tight tolerances, which are crucial in applications like facades, metal roofing, and decorative panels.

- High Speed and Efficiency: With high-powered lasers, you can cut through a variety of materials quickly, ensuring that large-scale projects like steel structure fabrication or aluminum framework production can stay on schedule. For industries that work with high volumes of material, such as pipe cutting for plumbing or HVAC systems, fiber lasers can significantly boost productivity.

- Versatility in Materials: Fiber laser machines can handle various building materials, including steel, aluminum, copper, and even composite panels. Whether you're working on metal cladding, partition walls, or even custom window and door frames, fiber laser technology provides the flexibility to work across diverse material types and thicknesses, from thin sheets to thick structural beams.

- Reduced Material Waste: Fiber lasers are known for their precision, which leads to optimized material usage. This is particularly useful in high-cost materials like stainless steel or aluminum commonly used in elevators, architectural exteriors, and load-bearing beams.

- Customizable Designs: Fiber laser machines are perfect for cutting intricate and complex designs, allowing manufacturers to create custom-built architectural features, such as metal staircases, ornate gates, and decorative metalwork.

Let Laser help you in these scenes!

Bodor Laser ' s fiber laser machines are widely used in various applications within the building materials industry, including:

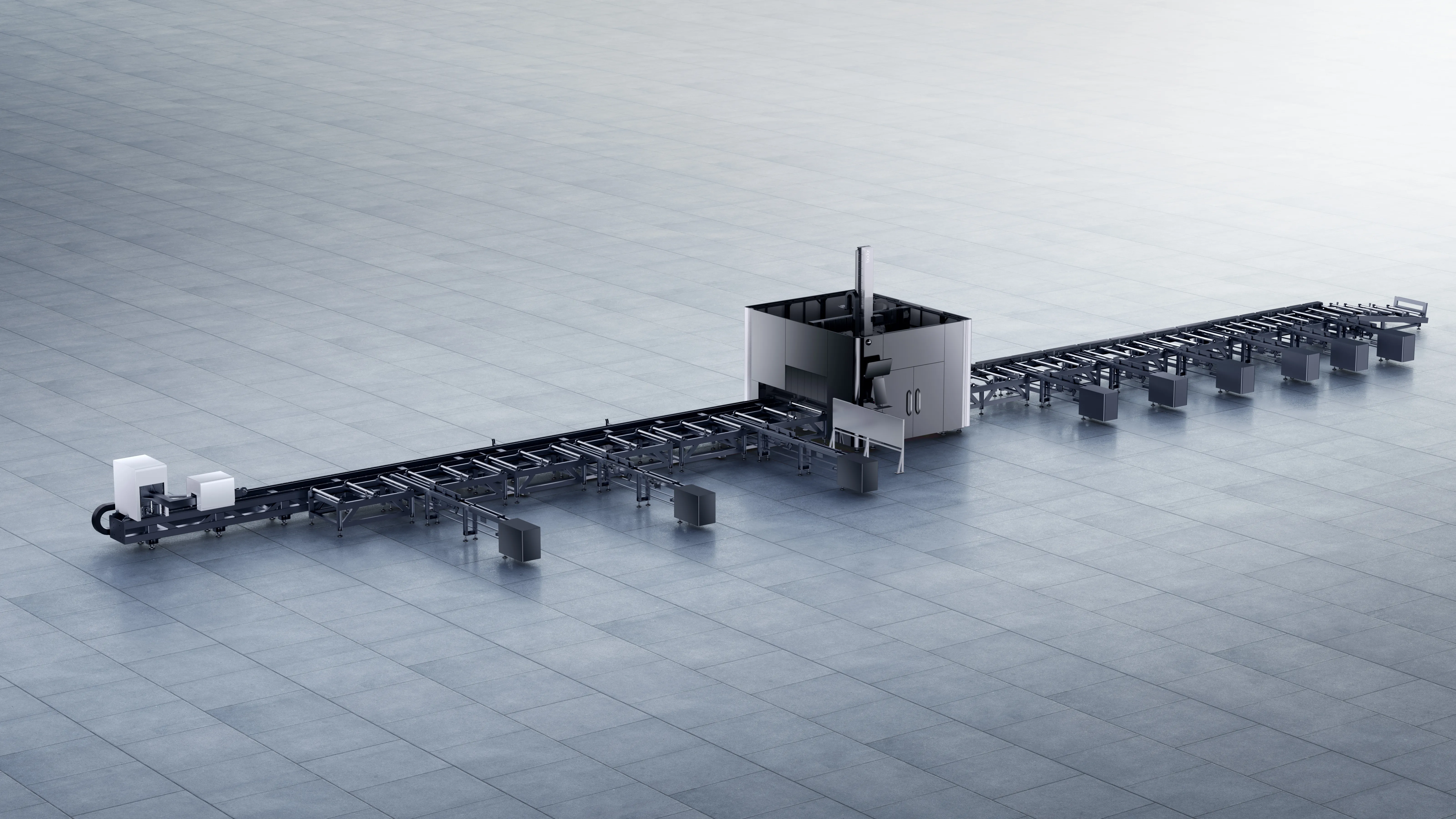

Structural Steel Fabrication: From steel beams to columns, fiber lasers ensure precise cutting, reducing assembly time for large construction projects. U10 pro, special for structural cutting, adaptation Tekla. More details about the U10 pro.

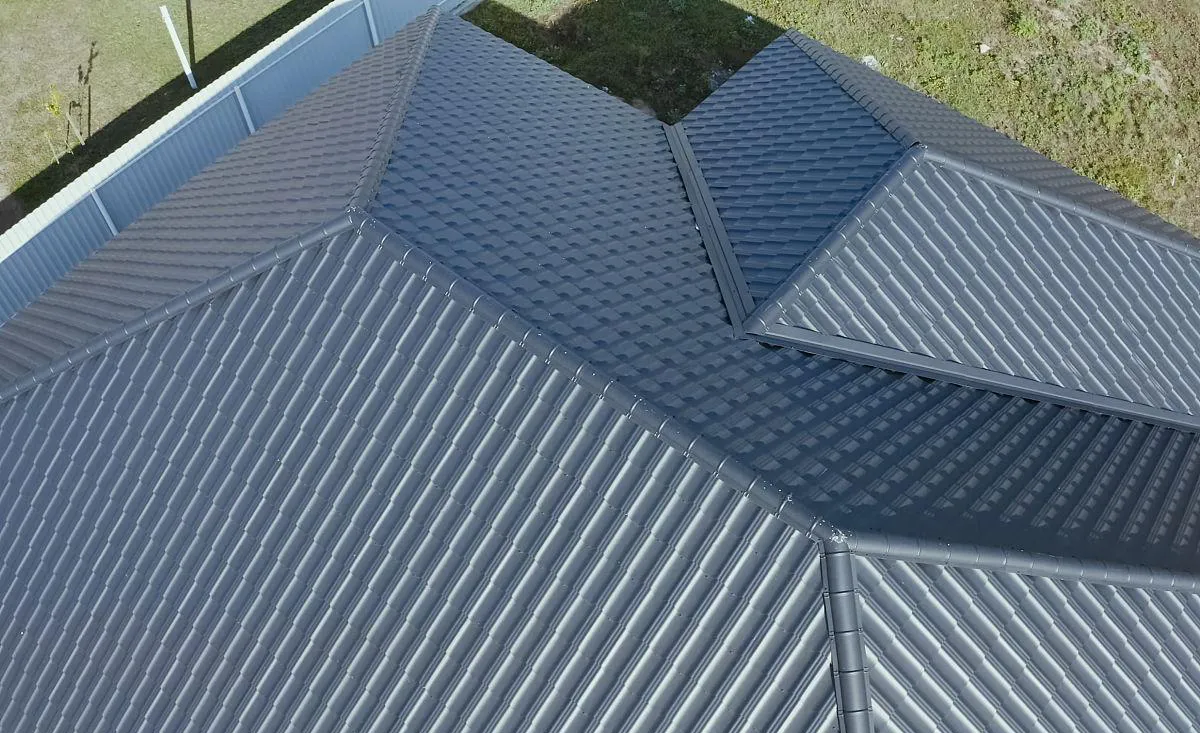

Metal Roofing and Facades: Fiber lasers offer the capability to cut and shape metal sheets used for roofing and exterior facades, delivering both functionality and aesthetic appeal. P series, professional sheet cutting machine, high performance with the intelligent optimization cutting function . More details about the P series.

Pipe and Tube Cutting: With specialized attachments, Bodor' s machines can handle tube cutting for plumbing, structural supports, and more, providing a versatile tool for construction firms. T series, professional tube cutting machine, suitable for round tube, square tube, section steel, special type tube, etc. More details about the T series.

Decorative Metalwork: Architects often require custom decorative panels and ornamental designs for building facades and interiors. Fiber lasers provide the intricate cutting necessary to bring these designs to life. Bodor provides free cutting software that can handle complex designs. You only need to import the drawing, supporting common drawing formats such as DXF, DWG, and G-code.

Bodor Laser' s machines have been instrumental in projects ranging from steel structure fabrication to the manufacture of facades and decorative panels. These machines ensure accuracy in both heavy-duty applications and aesthetic architectural features.

Elevate Your Cutting Capabilities with Bodor Laser

Bodor Laser' s machines have been instrumental in transforming the way building materials are cut, from steel structure fabrication to the production of facades and decorative panels. Their machines guarantee precision in both heavy-duty applications and intricate architectural designs.

As the construction industry continues to push for innovation, upgrading your cutting processes with Bodor Laser ' s fiber laser machines is the logical next step. From enhanced precision and speed to unparalleled versatility and cost savings, these machines are designed to meet the evolving needs of modern construction projects.

Ready to revolutionize your building material cutting? Explore Bodor Laser ' s cutting-edge fiber laser machines today and take your projects to the next level. Learn more.

Leave a comment

Your email address will not be published. Required fields are marked*