Laser Cutting Experts' Guide: From Basics to Pro Tricks

Learn essential and advanced laser cutting tips to boost your productivity. Discover expert tricks, recommended settings, and software tools that help you cut cleaner, faster, and more cost-effectively with fiber laser machines.

Cici

Mar 30, 2025Explore Laser Cutting Experts' Secrets.

Whether you're new to laser cutting or already running a production line, there's always something you can do to cut smarter, faster, and better. Today, we’re sharing practical tips—from beginner basics to pro-level tricks—to help you make the most of your fiber laser cutting machine.

Let’s dive into the best cutting!

Step 1: Don’t Skip the Basics

Even experienced operators sometimes overlook these essential checks:

Focus Point Accuracy

Ensure the laser’s focus is at or slightly below the material surface. Too high or too low? Expect burrs and burnt edges.

Pro tip: For carbon steel under 4mm, keep the focus at 0 mm (on the surface). For stainless steel or aluminum under 2mm, try a slight defocus of -1 mm for cleaner edges.

Match Gas to Material

Oxygen → Carbon steel (fast but oxidized edges)

Nitrogen → Stainless steel & aluminum (clean, oxidation-free)

Air → Thin mild steel (budget-friendly)

Example: One Bodor customer cutting 3mm carbon steel panels for furniture frames switched from nitrogen to air and cut gas costs by 60% without compromising quality.

Keep Nozzle Height Consistent

Too close = collision risk. Too far = a messy cut. Maintain stable height for better quality.

Recommended: 0.8–1.2 mm for most applications. Use automatic height control for consistent results.

Step 2: Upgrade with Pro Techniques

These tricks go beyond the basics and give you an edge in quality and efficiency:

Use Micro-Joints for Small Parts

Add tiny tabs to prevent small pieces from tipping or moving—this avoids damaged parts and protects your laser head.

When to use: Parts smaller than 50mm in any direction, or thin sheets (<1.5mm) that are prone to lifting.

Nest Smarter, Not Harder

Use intelligent nesting to arrange parts efficiently on the sheet. Bodor software does this automatically—maximizing material, minimizing scrap.

Case study: A sheet metal shop using BodorNest increased material utilization from 72% to 89% in just one month.

Avoid Burn Marks on Thin Stainless

Lower power slightly and speed up feed rate when cutting thin stainless. It keeps edges clean, especially with nitrogen.

Try Air Cutting for Thin Sheets

Air can reduce gas costs by up to 70%. Ideal for mild steel under 2mm or non-critical finishes.

Example: Try 1200W with 3 bar air pressure on 1.5mm mild steel for bracket production.

Balance Speed & Quality

Speed isn’t everything. Precision parts need that sweet spot between speed and accuracy.

Tip: For gear cutting or parts with tight tolerance (<0.1mm), reduce speed by 10–15% to minimize thermal drift.

Step 3: Let Smart Software Do the Work

Modern Bodor machines come with advanced features that make your job easier:

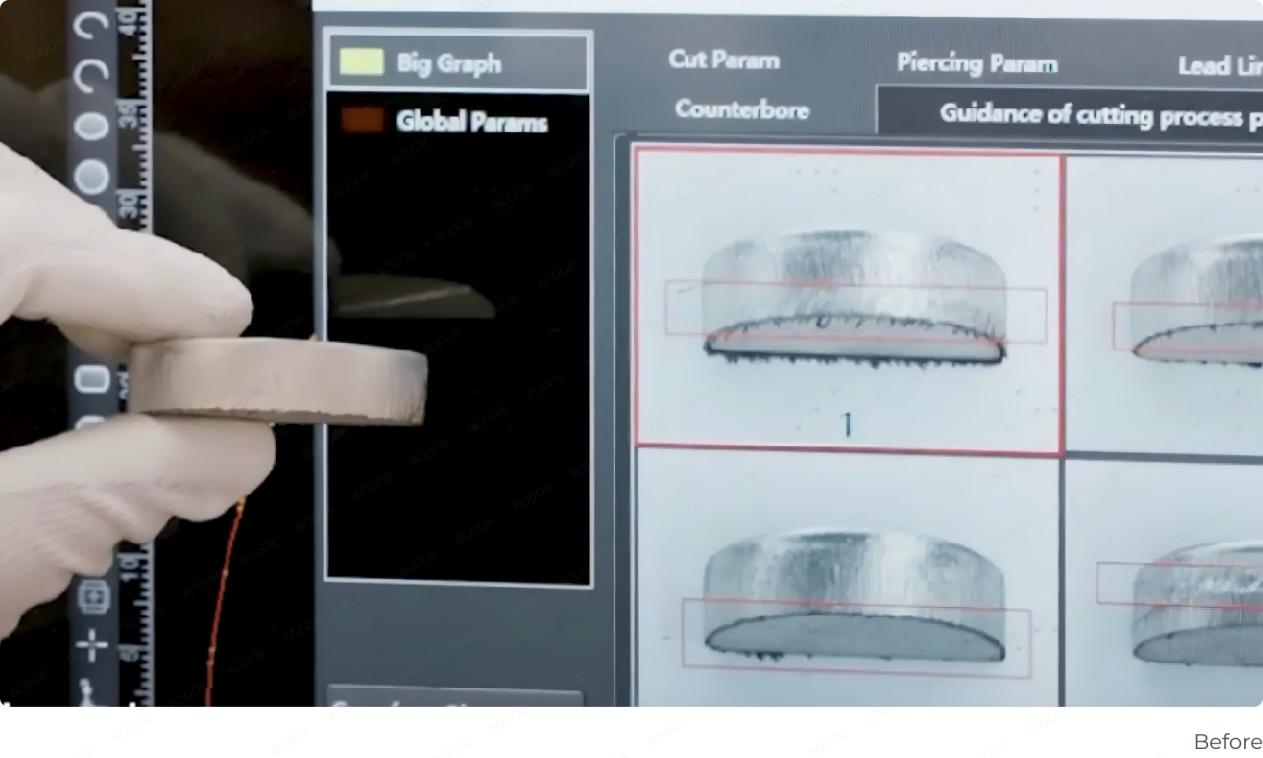

Intelligent Cutting Parameter Auto-Match

Powered by the BodorThinker system, it automatically identifies materials and graphics and matches optimal cutting parameters with one click. It reduces trial-and-error setup time, lowers the skill barrier, and enables even beginners to achieve high-quality cutting easily. Boost efficiency, extend machine lifespan, and make processing simpler and more professional.

Remnant Layout

Easily reuse leftover sheets by uploading a photo—no extra hardware needed. BodorNest automatically recognizes the remnant shape and nests parts efficiently, maximizing material utilization, cutting costs, and turning waste into value.

Don’t skip these features—they’re built to save your time and improve consistency.

Pro Tip: Don’t overlook these tools—they save time, and money, and prevent human error.

Step 4: Expert-Level Cutting Techniques

Want to go from great to elite? Try these advanced strategies:

Fine-Tune Like a Pro

Use dynamic focus, advanced piercing methods, and speed segmentation for tricky or thick materials.

Example: When cutting 10mm carbon steel, use gradual piercing with low power (40%) for cleaner entry points and longer nozzle life.

Master Thermal Control

Avoid heat warping by alternating cut zones, skipping areas, or using leapfrog cutting sequences.

Real tip: On large thin panels, cut non-adjacent parts first to let the metal cool before returning to the remaining sections.

Optimize Gas Use

Try switching gases mid-process based on part type. For example, oxygen for rough cuts, and nitrogen for clean finishes.

Advanced setting: Bodor systems can automate this with programmable layers in the nesting software.

Build a Custom Process Library

Keep track of what works—record your best settings by material, thickness, and design. Over time, this becomes a powerful knowledge base.

Suggestion: Create folders like "SS-2mm-decorative", "CS-6mm-brackets", and attach photos of results for future reference.

Go Automated

Connect your laser cutter with robotic loaders, unloaders, or MES platforms for seamless scheduling and batch tracking.

Step 5: Maintenance = Long-Term Performance

Even the smartest tech needs care. Make this checklist a habit:

Clean lens and nozzle regularly

Monitor gas purity and pressure

Clear slag buildup from cutting bed

Calibrate the laser head every few weeks

For a more professional laser maintenance manual, Learn More.

It’s More Than Just Cutting

Laser cutting isn’t just about turning on a machine—it’s about applying the right skills, tools, and habits. Whether you're creating car parts, steel structures, or fine art, these tips help you cut faster, cleaner, and smarter.

Looking to upgrade your workflow? Bodor combines precision hardware and intelligent software to help manufacturers stay ahead.

Ready to level up? Contact us now for the latest technology!

Leave a comment

Your email address will not be published. Required fields are marked*