Laser-Cutting Automation Improves The Manufacturing Efficiency of Fitness Equipment.

Discover how Bodor's automated laser cutting machines revolutionize the fitness equipment industry with precise cuts, faster production, and cost-effective solutions. Learn more about how automation boosts efficiency and quality in manufacturing.

Cici

Feb 12, 2025Stronger Cuts, Smarter Automation—Power Your Fitness Equipment with Bodor!

If you’re already using laser cutting machines for your fitness equipment manufacturing, you’ve seen the benefits of precision and speed. But have you considered taking it a step further? Upgrading to automated laser cutting could be the game-changer your production line needs. Automation not only enhances efficiency and accuracy but also significantly reduces costs and turnaround time, giving your business the competitive edge in a rapidly evolving market.

Why Laser Cutting Matters in Fitness Equipment

Fitness equipment needs to be strong, durable, and safe to use. This means the metal parts must be cut with extreme accuracy. If the parts are not cut accurately, it will directly affect the subsequent welding effect, thus affecting the quality of the finished fitness equipment. Traditional cutting methods, like saws or shears, often leave rough edges or cannot achieve the correct shapes. But the cutting effect of the laser cutting machine is completely different.

Laser cutting uses a focused beam of light to cut through metal like a knife through butter. It's fast, precise, and leaves a clean edge. Whether it's the frame of a treadmill or the handles of a weight machine, laser cutting ensures that every part is cut to perfection.

Automation: The Game Buff

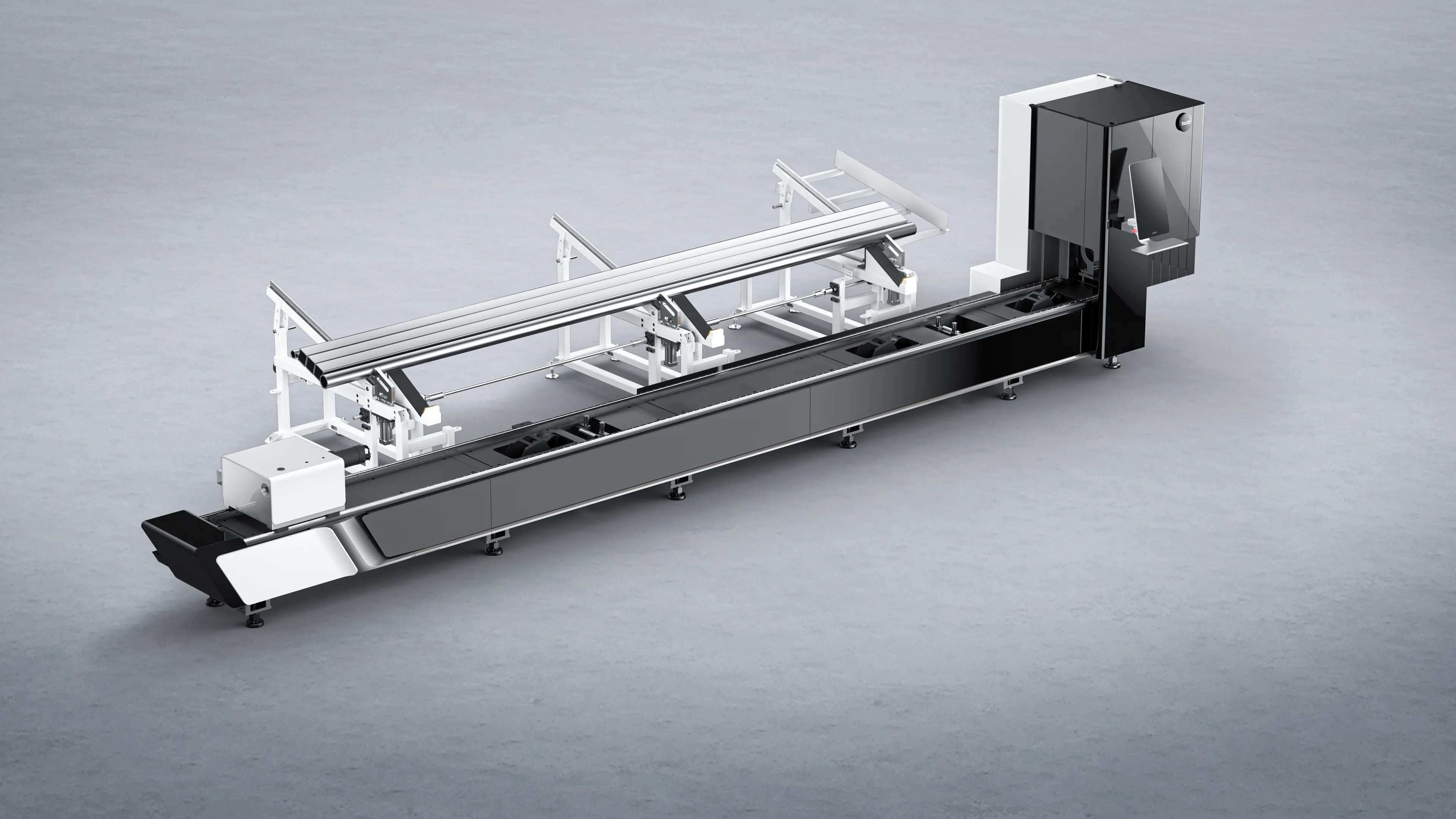

One of the biggest advantages of Bodor's laser cutting machines is their automation. In the past, cutting metal was a time-consuming process that required skilled workers to operate the machines. With automation equipment, the cutting process is faster and more efficient. Bodor's automatic tube laser cutting machine can cut steel pipes in batches without manual loading and unloading. This not only speeds up production but also reduces the chance of human error.

For fitness equipment manufacturers, this is a game-changer. Automated laser cutting allows them to produce more parts in the same amount of time with fewer labor costs than non-automated laser cutting machines. This significantly boosts the company’s competitive edge in the market.

Many fitness equipment makers already use laser cutting machines, but adding automation will be a game-changer. Upgrading to automated cutters will bring new energy to your business. To learn more, contact our experts by clicking here: Contact us

Benefits for Fitness Equipment Manufacturing

1. Precision and Consistency: Compared to other cutting methods, fiber laser cutting machine provides better cutting accuracy. This means that every piece of equipment is made to the same size, ensuring consistent quality across all products.

2. Speed and Efficiency: Automated laser cutting is much faster than traditional methods. Bodor's machines can operate around the clock, cutting parts quickly. This helps manufacturers meet deadlines and produce large amounts of equipment in a short time.

3. Cost-Effectiveness: Although laser cutters are costly upfront, they pay off over time. Automation reduces the need for skilled labor, which lowers production costs. Plus, the precision of laser cutting means less waste, as there are fewer mistakes and less material wasted.

4. Flexibility: Fitness equipment comes in different shapes and sizes, and manufacturers often need to make custom parts. Bodor's laser cutting machines can be easily programmed to cut different shapes and sizes, offering the flexibility to meet various design needs.

Which automation can you choose?

Bodor offers different solutions:

● Semi-automatic

Place it manually on the storage stand piece by piece.

● Full-automatic

Place a bundle of pipes directly into the storage bin without manual arrangement.

Contact the salesperson for assistance

The Future of Fitness Equipment Manufacturing

As fitness trends continue to grow, so does the demand for high-quality fitness equipment. Manufacturers need to keep up with this demand while ensuring that their products are safe and durable. Bodor's automated laser cutting machines provide the perfect solution. With their speed, precision, and flexibility, these machines are helping manufacturers produce better equipment faster and at a lower cost.

In conclusion, Bodor's automated laser cutting machines are playing a crucial role in the fitness equipment industry. By making the production process faster, more efficient, and more precise, they're helping manufacturers meet the growing demand for top-quality fitness equipment.