Building the Future of Connectivity: The Application of Fiber Laser Cutting in Communication Tower Manufacturing

Fiber laser cutting is revolutionizing the communication tower manufacturing industry by offering unmatched precision and efficiency in cutting complex metal components like structural steel and tubular steel.

Enci

Jan 2, 2025The best fiber laser solution for your structural and tubular steel.

Introduction

Tele-communication towers are tall structures designed to support antennas and other telecommunications equipment. Their primary purpose is to transmit signals for mobile phones, television, radio, and data services. These towers come in several designs, including lattice towers, monopole towers and guyed Towers. Steel is the backbone of communication tower construction, valued for its strength, durability, and versatility. Both structural steel and tubular steel are engineered to support heavy equipment while maintaining a lightweight design, making them the ideal choice for modern telecom infrastructure. These materials ensure the towers can withstand the demands of heavy loads and harsh environmental conditions, all while delivering long-term reliability.

Why Communication Tower Need More Advanced Manufacturing Solutions?

As the telecommunications industry expands to meet the growing demands of 5G, IoT networks, and broadband connectivity, the need for high-performance communication towers has never been greater. Steel manufacturers play a pivotal role in this transformation, but they face increasing pressure to deliver components that meet exacting standards for:

1. Strength and Durability: Towers must endure harsh weather and provide reliable performance with minimal maintenance.

2. High Strength-to-Weight Ratio: Steel components must support heavy loads while keeping the structure lightweight for taller, more efficient designs.

3. Complex Designs: Modern towers require intricate, customized components to meet unique project specifications.

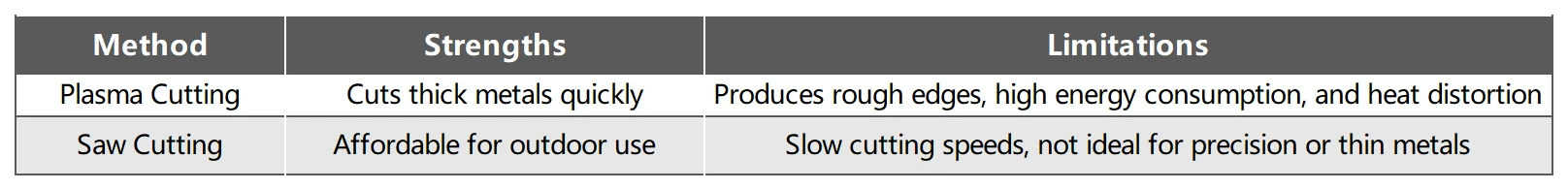

However, traditional cutting and welding methods often fall short when dealing with these challenges. These methods can be slow, lack precision, and lead to higher energy consumption and material waste.

While these traditional methods can be effective in certain applications, they often struggle with high-precision cuts and complex shapes required in modern communication tower designs. In contrast, fiber laser cutting technology offers significant advantages, providing faster speeds, cleaner cuts, and higher flexibility for intricate designs, enabling manufacturers to meet the evolving demands of the telecom industry with greater efficiency and accuracy.

Why Fiber laser is Solution?

The standout advantages of fiber lasers is their fast cutting speed and exceptional cutting precision. It can process tubular and structural steel much efficient, enabling manufacturers to meet tight deadlines without compromising quality. Moreover, modern communication towers often feature intricate lattice frameworks or unique shapes that traditional tools struggle to cut accurately. Fiber lasers excel at:

Complex Structures Handling:

1. Fiber laser cutting machines are highly adaptable, designed to meet the unique manufacturing needs of complex communication tower structures such as dead-end, angle, and cross structures. This flexibility ensures that the tower design aligns with specific project requirements with precision and efficiency.

2. Fiber lasers can process a wide range of structural steel types and configurations, including I-beams, H-beams, and L-shaped steel, providing manufacturers with the versatility to meet diverse structural demands

I beams H beams and L-shaped used in communication tower

High-Quality Cutting of Thick Steel:

Fiber lasers provide clean, precise cuts on structural steel and tubular steel, accommodating varying diameters and thicknesses.

1. Precision cutting is vital for maintaining the aerodynamics and structural integrity of tubular towers.

2. They easily manage intricate patterns, sharp angles, and tight curves, ensuring consistency and accuracy

.

Tubular steel in communication tower

Custom Design Capabilities:

Fiber lasers meet exact specifications for specialized components like brackets, flanges, and support beams, essential in tower construction. Their precision allows for custom cuts that ensure seamless integration of parts, even for complex or tailored designs.

With the demand for communication towers continuing to rise, especially in the context of 5G and beyond, advanced fiber laser manufacturing solutions will play a pivotal role in meeting the growing needs of the telecommunications industry. Investing in fiber laser technologies now ensures that your production line is ready for the challenges of tomorrow.

How Bodor Supports Your Business?

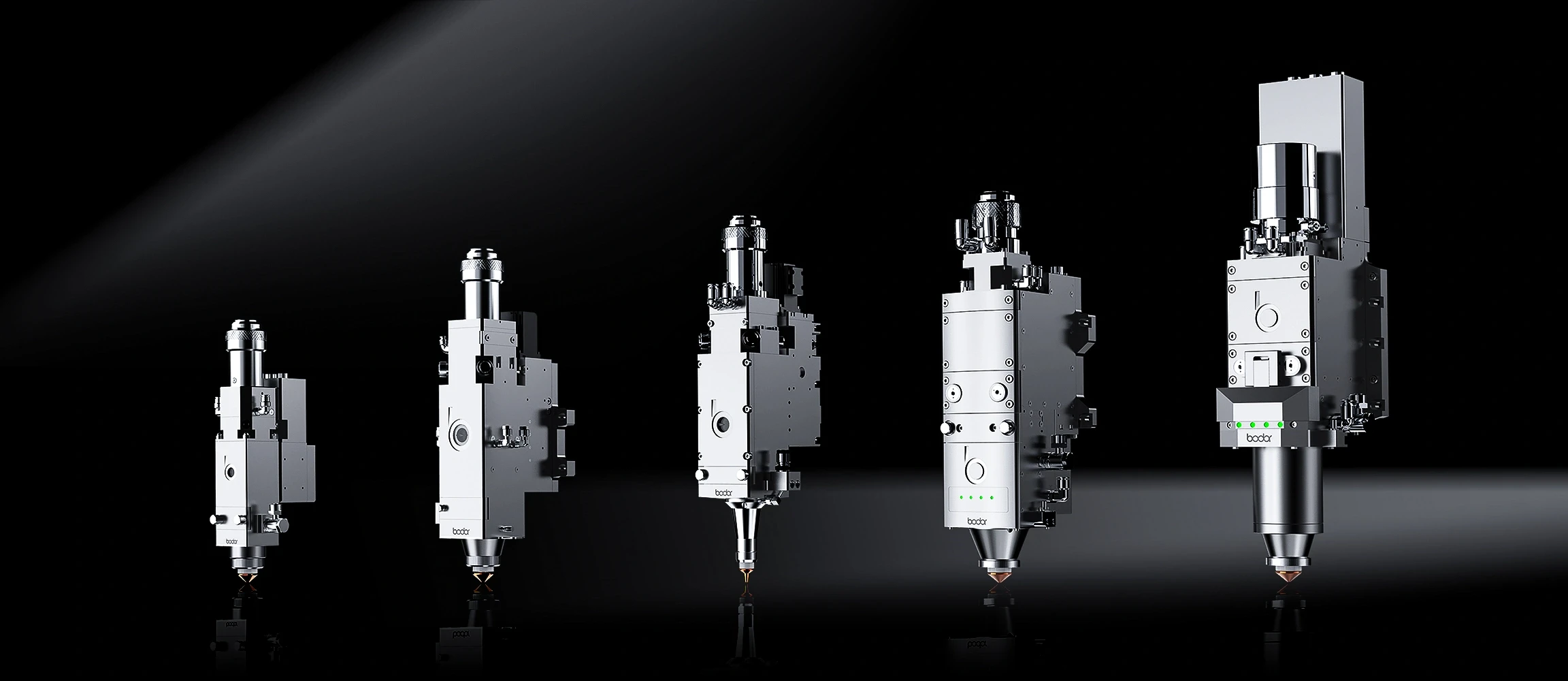

1. Core Technology for Better and Faster Cutting

BodorGenius intelligent laser head leverages advanced sensors and algorithms to detect obstacles like tilting parts and automatically avoids potential collisions. This technology significantly enhances cutting stability and operational efficiency, ensuring uninterrupted production. For manufacturers, this means a smoother workflow, reduced risk of damage to both the laser head and the material, and consistent high-quality cuts even in complex or large-scale projects.

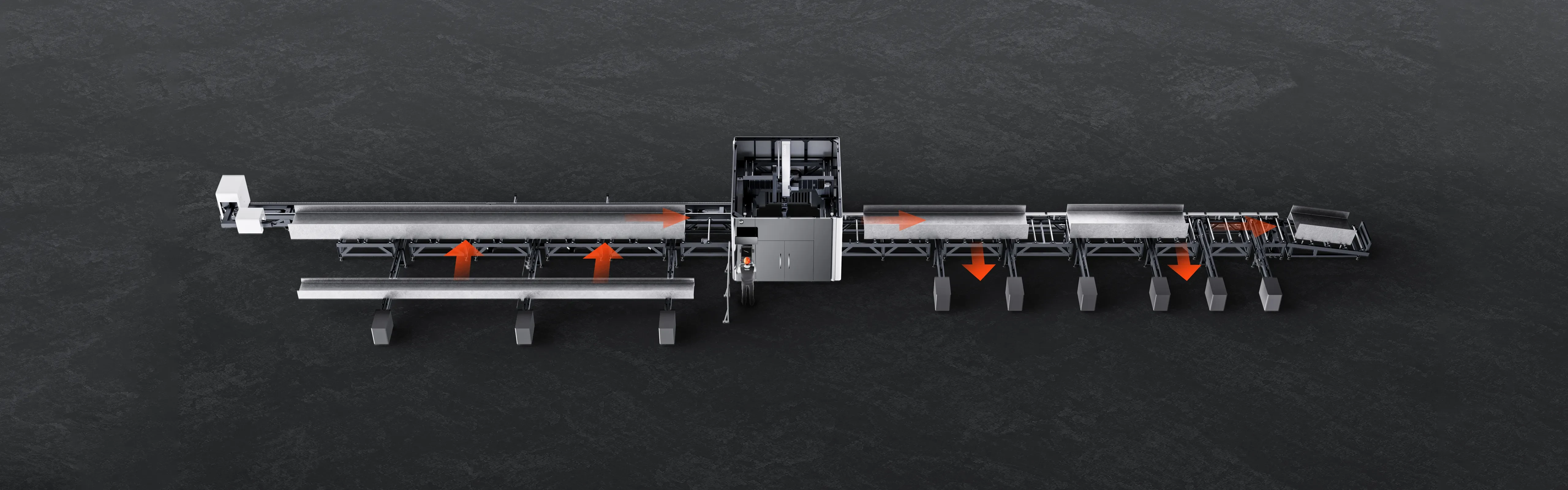

2. One Stop Processing Solution for Structural Steel

The U10 Pro High-Performance Profile Steel Laser Cutting Machine is a state-of-the-art solution that integrates multiple processes into a seamless operation. Combining loading, cutting, notching, hole-making, beveling, and unloading, the U10 Pro streamlines the production process, reducing the need for multiple machines and manual intervention. This all-in-one capability not only boosts efficiency but also ensures precision and consistency across a variety of profile steel applications. Designed to handle complex tasks with ease, the U10 Pro is ideal for industries requiring high-quality and versatile processing solutions.

3. High Automatic&Flexibility Processing Solution for Tube Cutting

The Bodor all-new M Series flagship tube laser machine revolutionizes tube cutting with its innovative Dual Process Parallel Processing capability. This advanced feature allows for simultaneous tube cutting and loading or simultaneous tube cutting and unloading, significantly boosting cutting efficiency while catering to diverse processing needs. Moreover, designed for heavy-duty applications, the M5 model is the ideal choice for large metal tube processing, capable of cutting tubes with diameters of up to 510 millimeters.

How to Get Started?

Adopting fiber laser technology is easier than you think. Here are a few steps to help get started:

1. Assess Your Needs: Identify bottlenecks in your manufacturing processes.

2. Choose suitable fiber laser solution: Look for a machine that can handle the steel thickness you typically work with is important. Leave your processing requirements here, our laser expert will contact you to provide tailored fiber laser cutting solution.

3. Training and Support: Its essential to invest in proper training for your team to ensure they can maximize the technology’s potential. Bodor offer free training and ongoing after-sale support for your team to ensure they’re equipped to use the laser cutting technology efficiently.

Conclusion:

The communication tower industry is evolving rapidly, and adopting advanced technologies like fiber lasers is essential for staying competitive. Fiber lasers offer manufacturers the precision, speed, and cost-efficiency needed to thrive in a demanding market. Whether you’re cutting, welding, or maintaining communication tower components, fiber lasers can help you achieve better results in less time and at lower costs.