Transforming Pressure Vessel Manufacturing with Bodor Laser Cutting Solutions

Pressure vessels are important in industries like food processing, pharmaceuticals, and renewable energy. They must meet strict safety and performance standards, which means their production requires high precision and reliability. Traditional cutting methods often fall short because of low accuracy, inefficiency, and high costs. Laser cutting technology solves these problems, improving production speed and product quality.

Cici

Dec 30, 2024Precision & Efficiency for Pressure Vessels!

In this post, we explain how laser cutting technology benefits pressure vessel manufacturing and helps companies achieve better results.

Key Advantages and Applications of Laser Cutting in Pressure Vessel Manufacturing

Laser cutting technology provides significant advantages for pressure vessel production, combining precision, efficiency, and versatility to meet the industry’s demanding requirements. Here’s how Bodor’s laser cutting machines transform the manufacturing process:

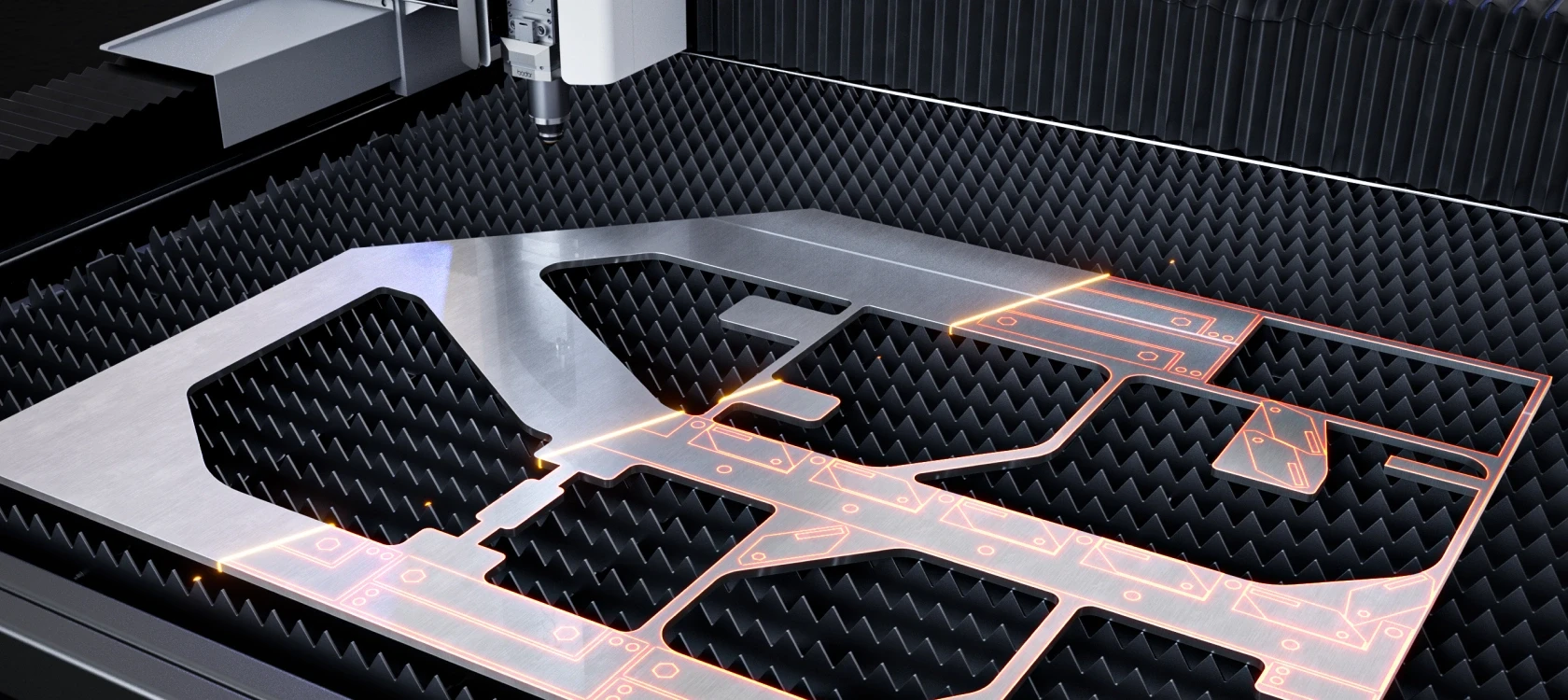

1. Precision and Quality

● Accurate Cutting for Thick Materials: We offer customized power options based on customer needs, enabling the cutting of carbon steel and stainless steel up to 80mm with exceptional precision and accuracy.

● Clean, Burr-Free Edges: Laser cutting provides smooth cutting surfaces, reducing or even eliminating the need for secondary polishing processes like grinding or buffing. Additionally, Bodor's self-developed system includes intelligent features such as Cutting Parameter AutoMatch, which helps customers optimize cutting surfaces with system-generated prompts.

● Batch Consistency: Whether producing shells, heads, or nozzles, laser cutting ensures uniform quality across batches, meeting ASME and ISO certifications.

2. Material Efficiency

● Minimal Material Waste: A narrow kerf width reduces material loss. This is very important for expensive metals like stainless steel and alloys.

● Optimized Material Usage: Remnant Layout, an intelligent feature in the BodorThinker control system, maximizes sheet utilization and reduces scrap by using optimized algorithms, nesting techniques, and a deep learning module for smarter layout adjustments.

3. Speed and Productivity

● High-Speed Cutting for Large Volumes: Laser systems operate significantly faster than traditional methods, reducing production times for pressure vessel components.

● Quick Adaptability: Easily switch between designs or material thicknesses, ideal for custom or varied production needs.

4. Flexibility for Custom Designs

● Support for Complex Geometries: Laser cutting excels at intricate patterns, curved edges, and precision cutouts, essential for advanced vessel designs.

● Versatile Material Handling: Process a wide range of metals, from carbon steel to aluminum alloys, to meet diverse requirements.

● Effortless Customization: Quickly adapt to unique designs without extensive retooling, reducing lead times and costs.

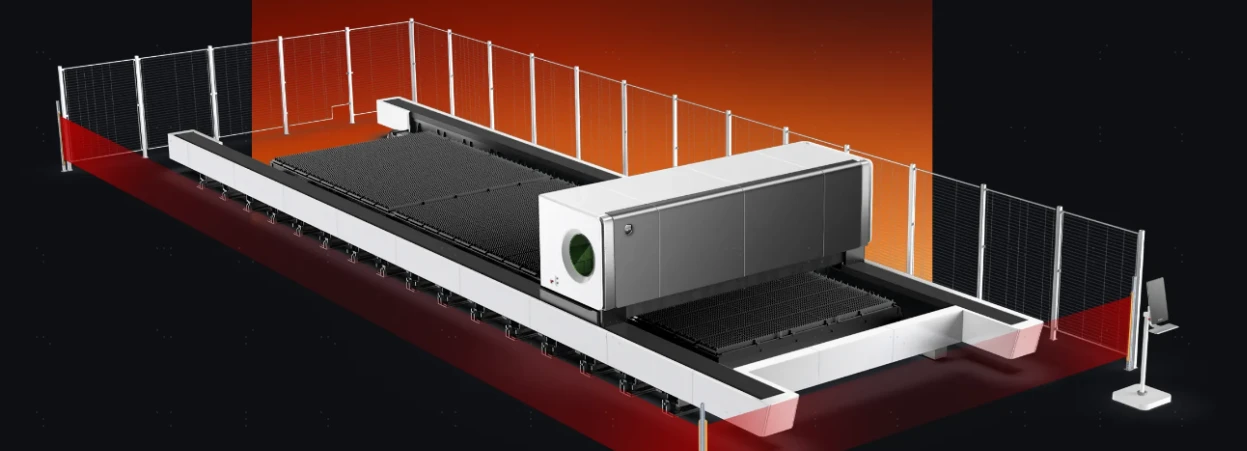

Bodor’s Cutting-Edge Solution: H Series Laser Cutting Machine

The Large-format H Series Laser Cutting Machine is purpose-built for large-scale processing needs, offering unmatched capabilities:

1. Processing Size: 12500mm*3200mm to 24500mm*3200mm

Fits the large sizes needed for pressure vessel parts. This allows for easy production of big pieces like vessel heads and cylindrical sections.

2. Bevel-Cutting Feature: Optional for advanced applications

Perfect for creating angled cuts necessary for precise welding preparation, ensuring strong, reliable joints in pressure vessels.

3. High-Power Options: Available in 12kW to 60kW

Cuts through high-strength alloys and thick materials effortlessly, meeting the stringent demands of pressure vessel manufacturing.

With intelligent automation and precision features, the H Series is ideal for pressure vessel manufacturing. Discover more intelligent features here.

The Future of Pressure Vessel Manufacturing

Laser cutting technology is revolutionizing how pressure vessels are made. The combination of precision, efficiency, and defect reduction empowers manufacturers to create stronger, more reliable products while optimizing production timelines.

Are you ready to enhance your pressure vessel manufacturing process? Let Bodor help you transform your production line and achieve unparalleled quality and performance.

Leave a comment

Your email address will not be published. Required fields are marked*