Bodor Rocut

Classic Model | Automatic Coiled Sheet Laser Cutting Machine

Inquire Now

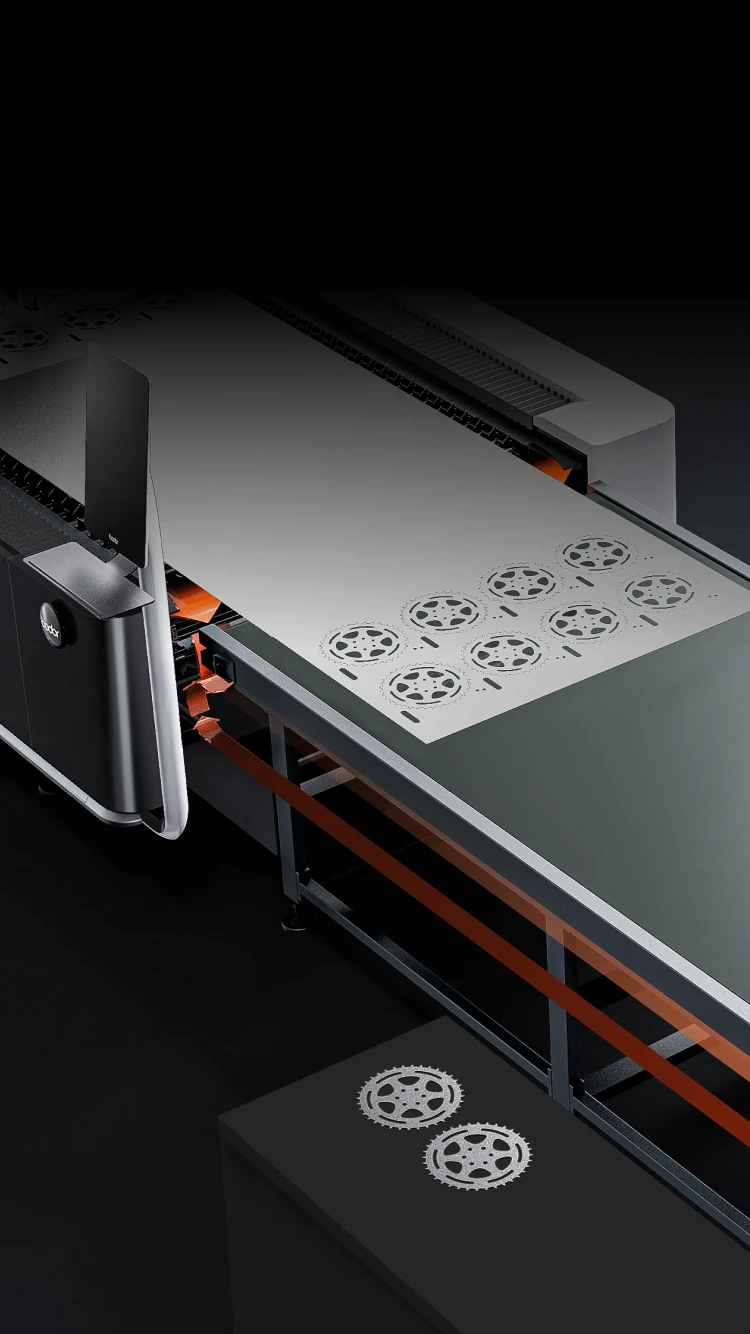

Uncoiling, leveling, and cutting all in one step.

Multi-use machine handles materials seamlessly.

The Rocut handles full steel coil processing in one go — integrating uncoiling, leveling, and cutting for seamless workflow.

Start saving from the first cut. The Rocut's continuous nesting optimizes coil material use, slashing scrap and component costs significantly.

No manual intervention is required, saving manual operation time. Standard parameters, one-click start, simple and easy to use.

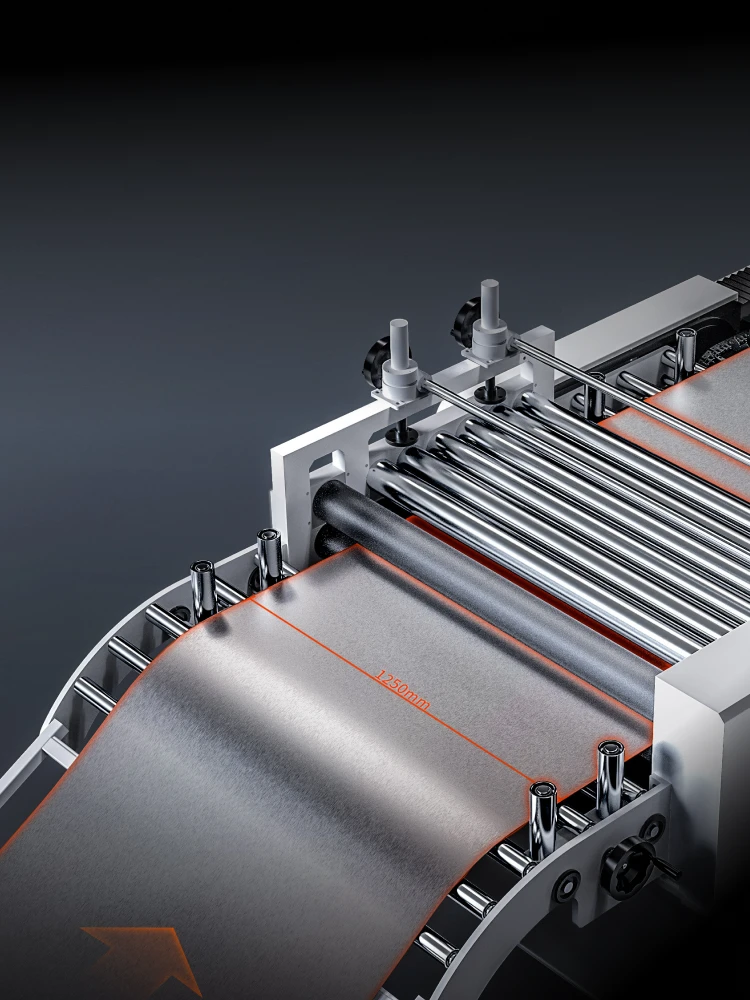

Standard dual-station uncoiler, with up to 6 optional uncoiler stations, allows for loading various

materials and thicknesses, without stopping for material changes due to station limitations.

It saves time and effort, improving production efficiency.

Standard dual-station uncoiler, with up to 6 optional uncoiler stations, allows for loading

various materials and thicknesses, without stopping for material changes due to station

limitations.

It saves time and effort, improving production efficiency.

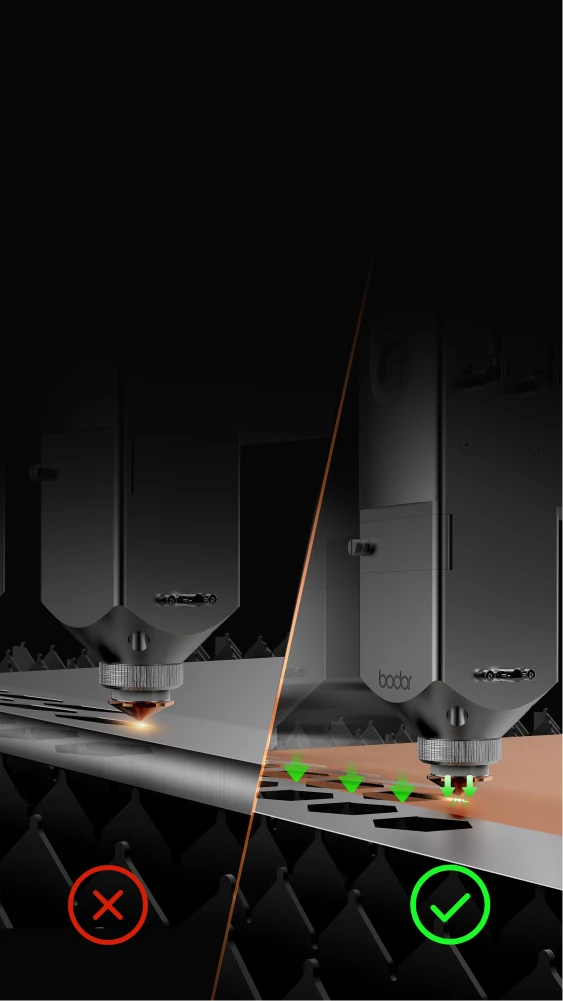

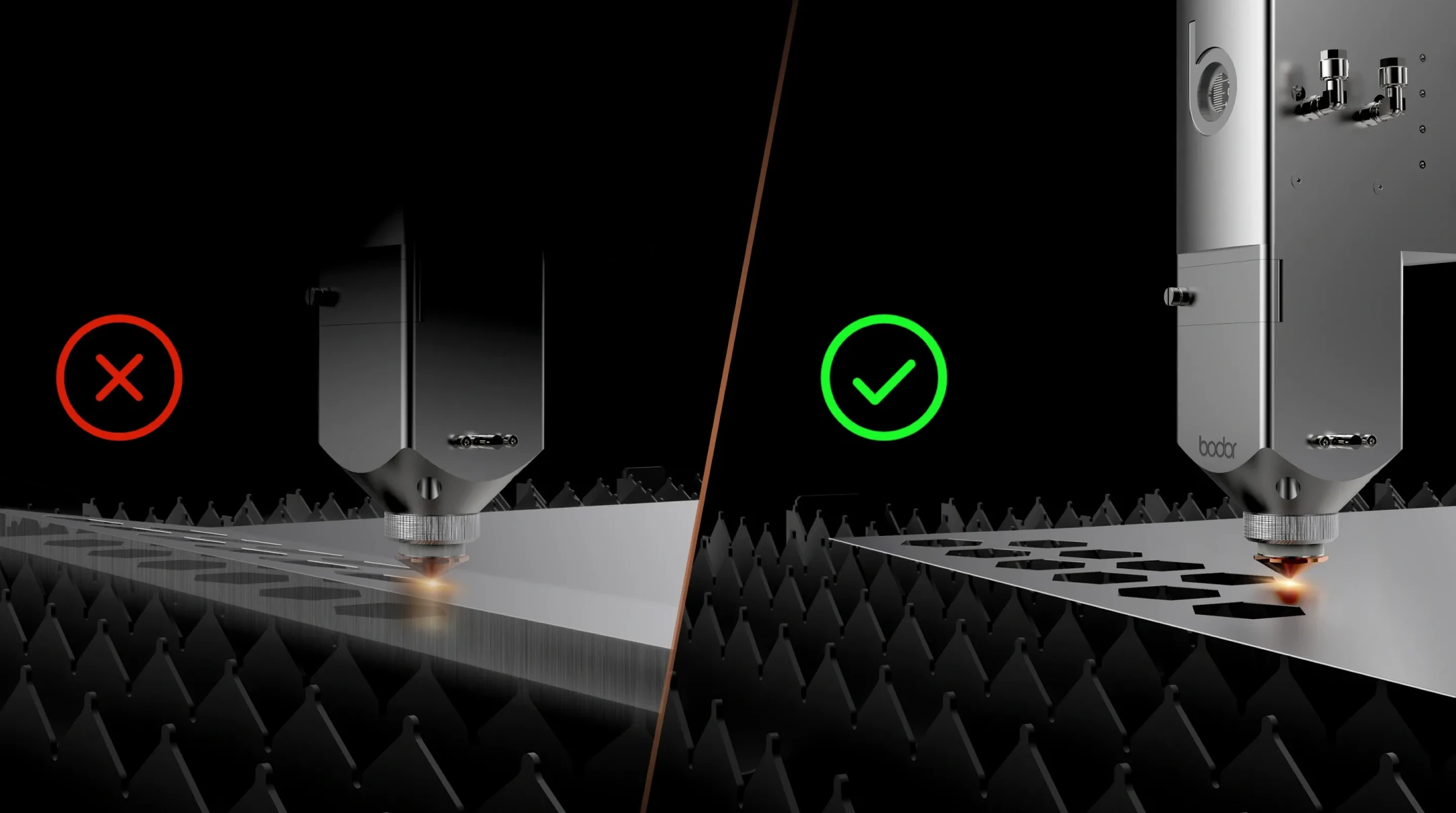

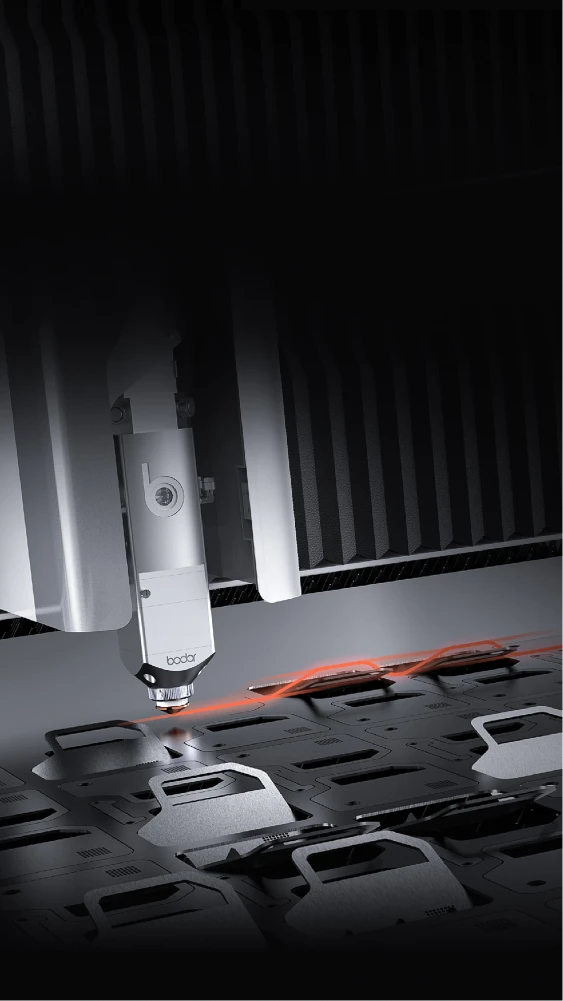

Through the powerful algorithm, it is able to adapt to the high-frequency vibration of thin sheets due to air pressure. The laser head sensitivity is intelligently adjusted, ensuring consistently stable cutting, thereby guaranteeing both cutting quality and efficiency.

Through the powerful algorithm, it is able to adapt to the high-frequency vibration of thin sheets due to air pressure. The laser head sensitivity is intelligently adjusted, ensuring consistently stable cutting, thereby guaranteeing both cutting quality and efficiency.

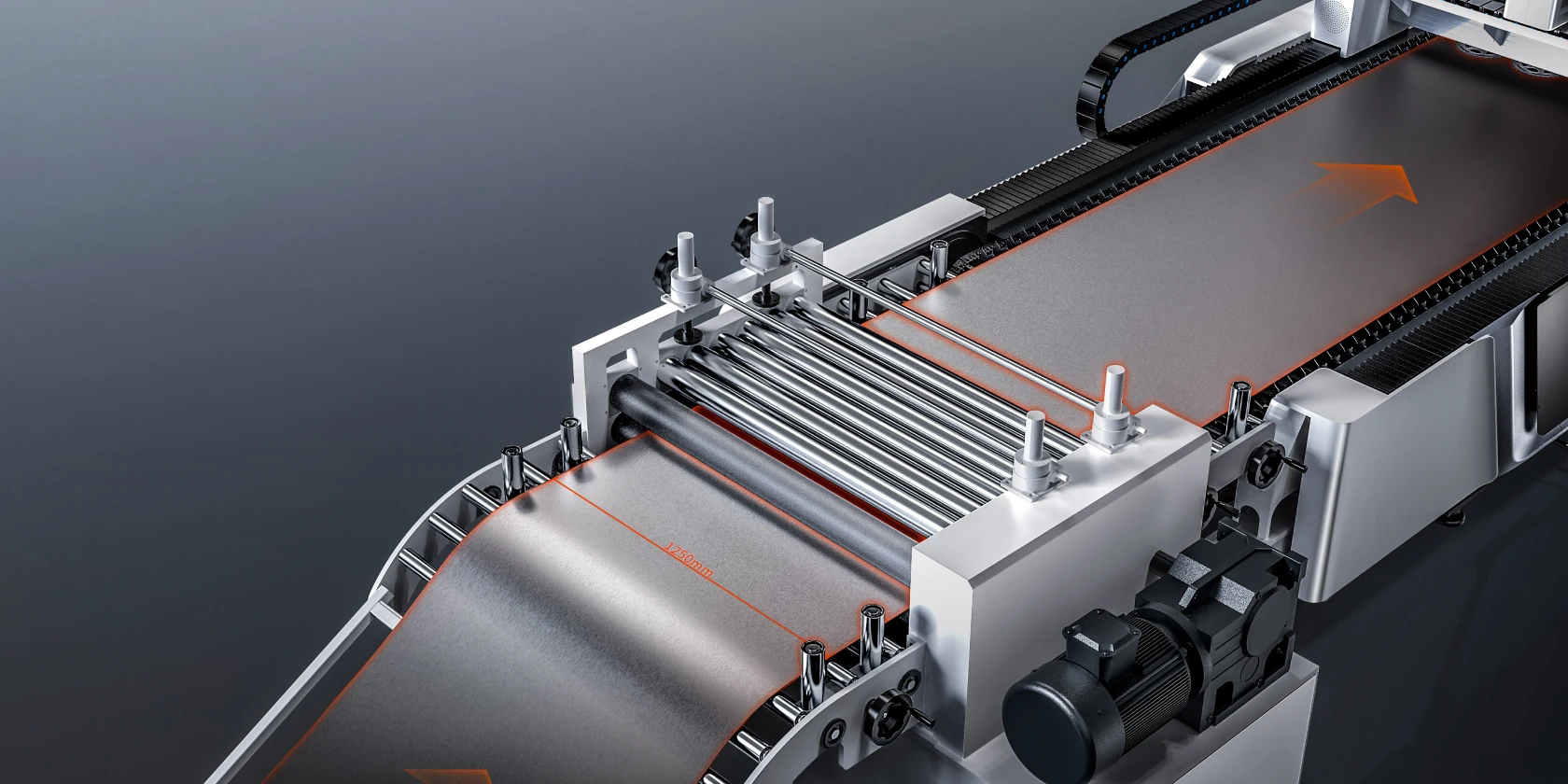

The ultimate size reduces redundancy in the coiled sheet laser cutting machine. The 1250mm size perfectly saves floor space.

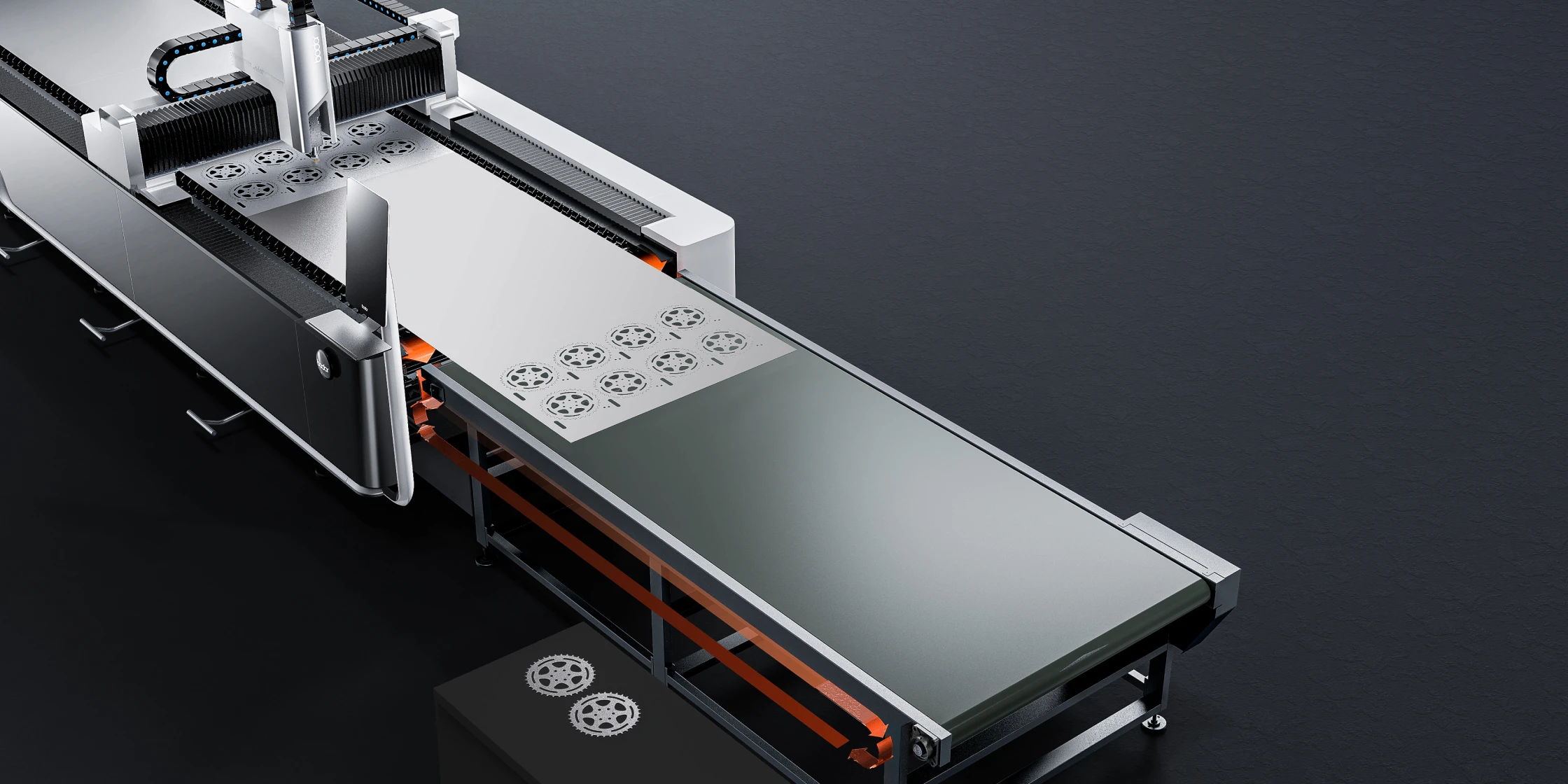

Optional workpieces receiving platform transports workpieces timely, facilitating sorting automatically.

Reduce Material Remnants,1250mm Perfect Size Saves Space

Self-developed servo-following sensors and path avoidance algorithms can accurately sense obstacles in real-time at 360° in the operating path, and plan the obstacle avoidance route in advance to reduce the risk of laser head collision significantly.

Self-developed servo-following sensors and path avoidance algorithms can accurately sense obstacles in real-time at 360° in the operating path, and plan the obstacle avoidance route in advance to reduce the risk of laser head collision significantly.

Regardless of whether you require general advice or specific support, we are happy to help you.