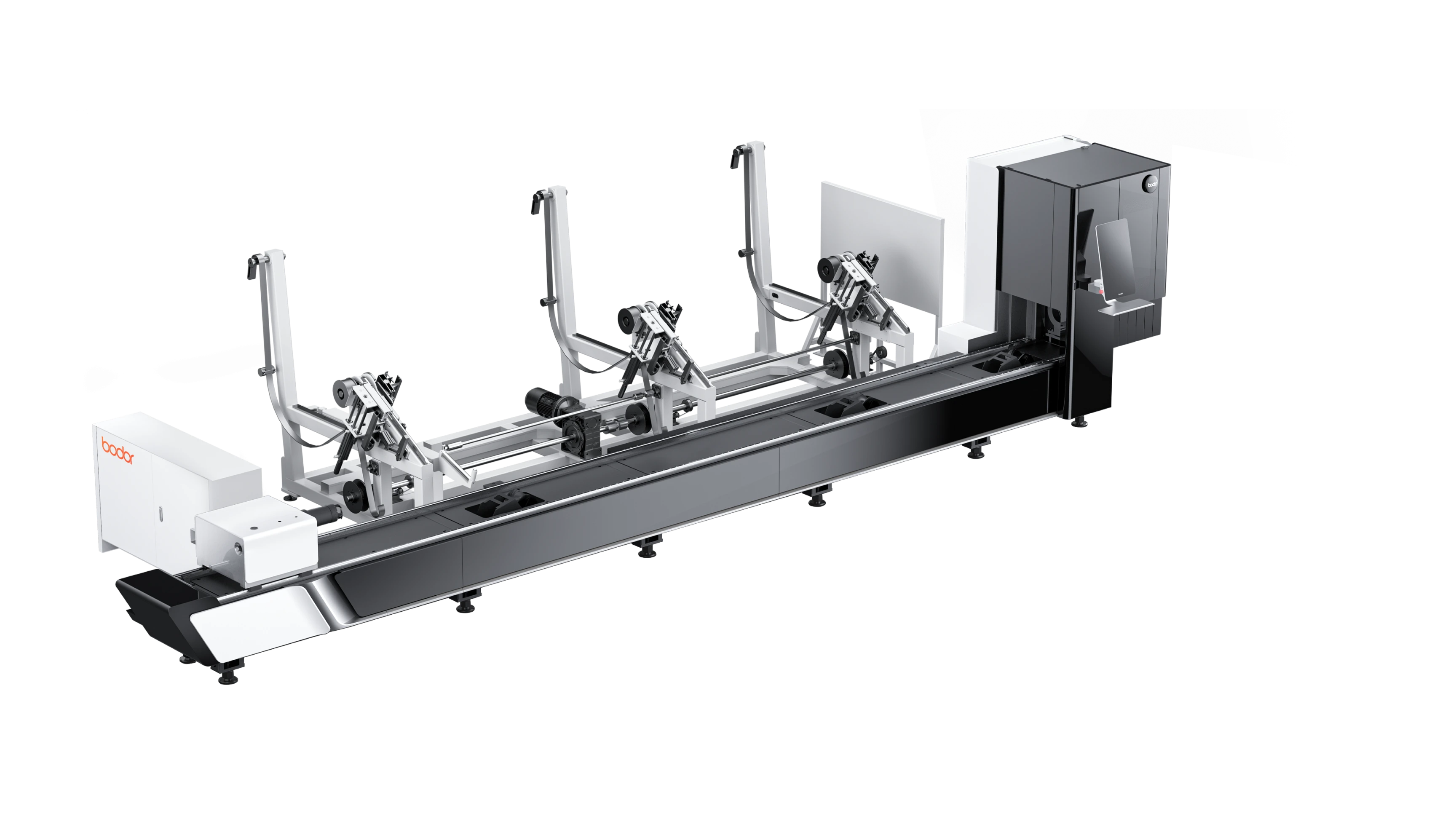

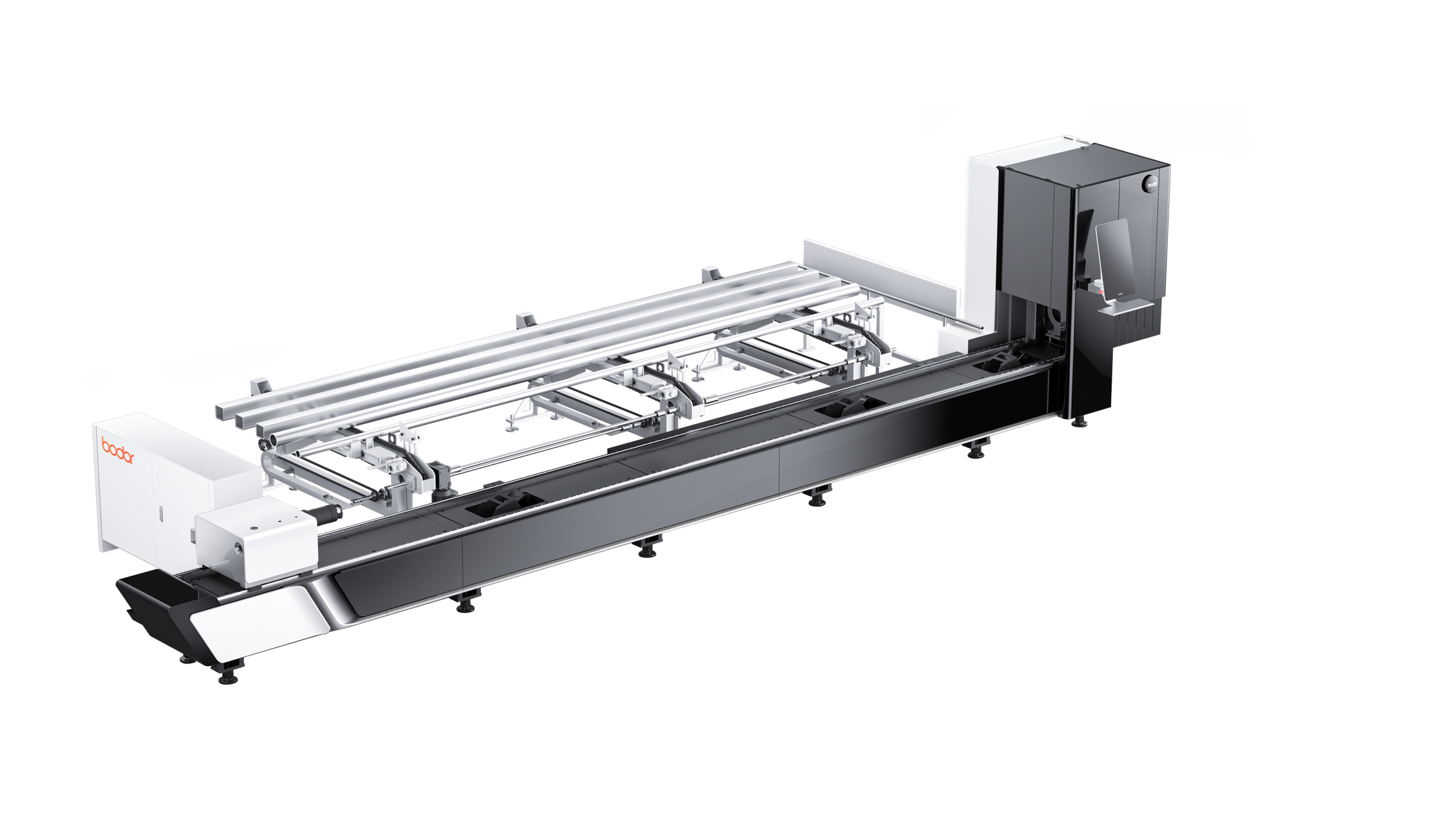

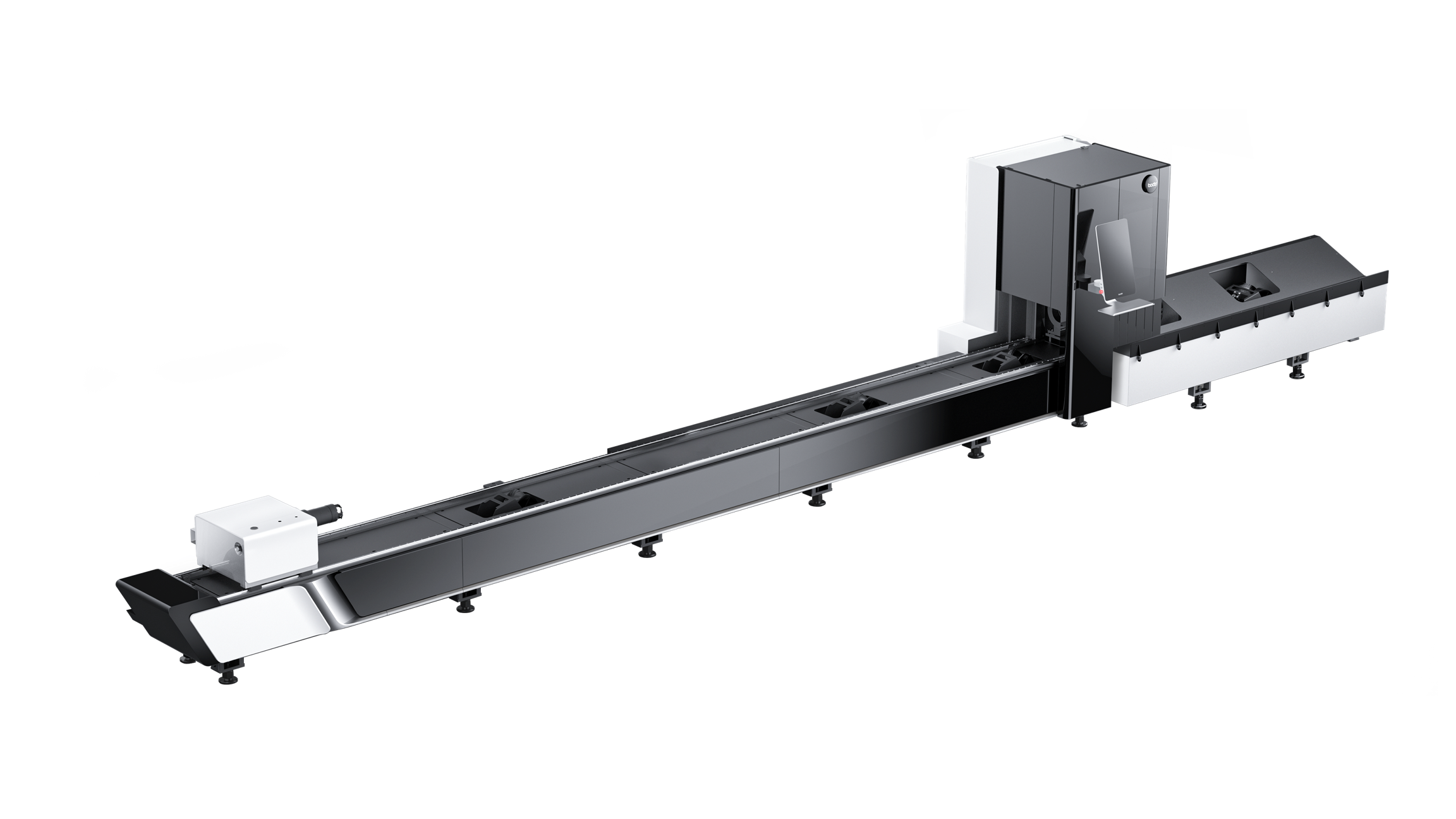

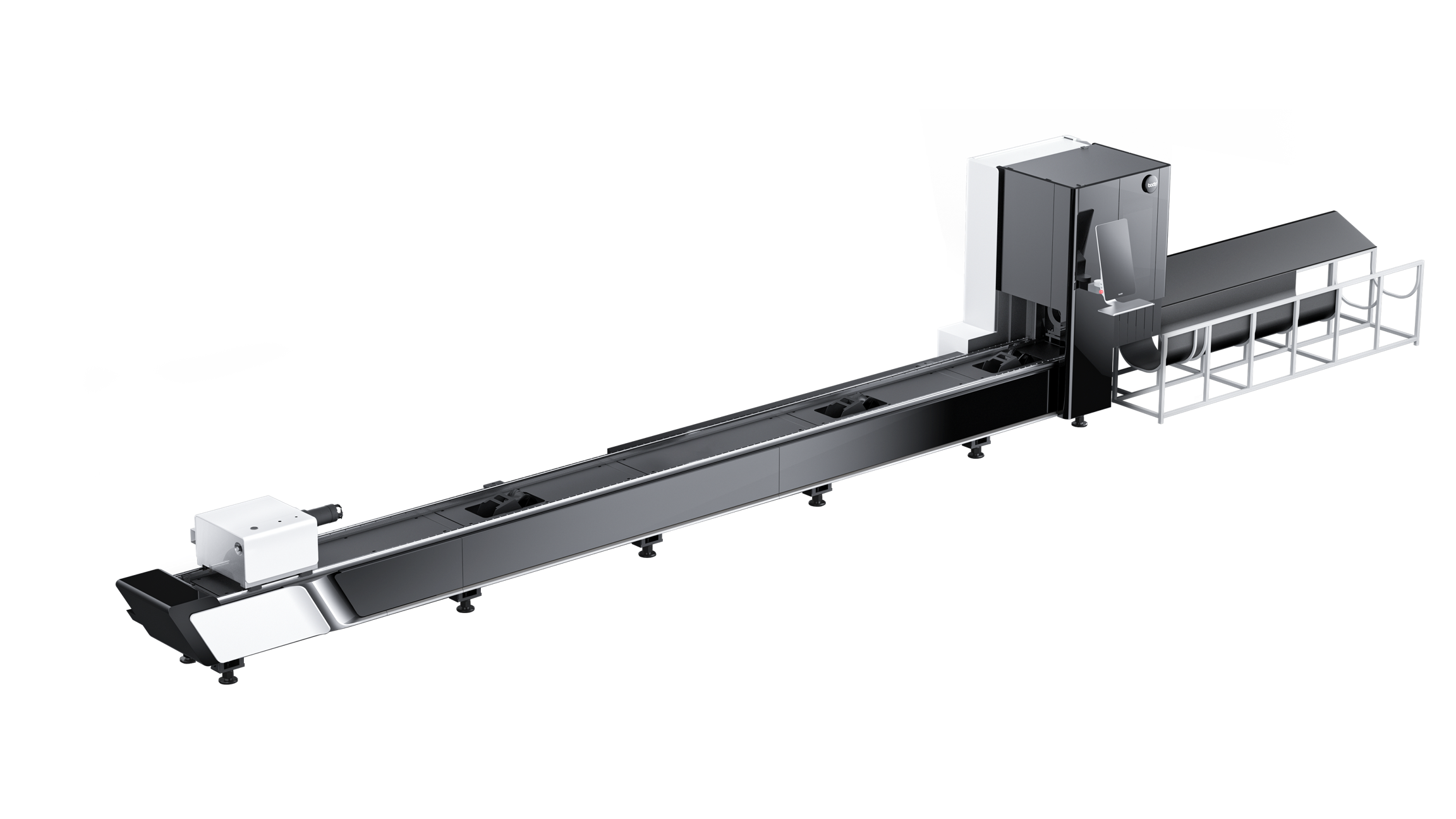

Bodor K

Classic Model | Tube Laser Cutting Machine

Industry Bestseller

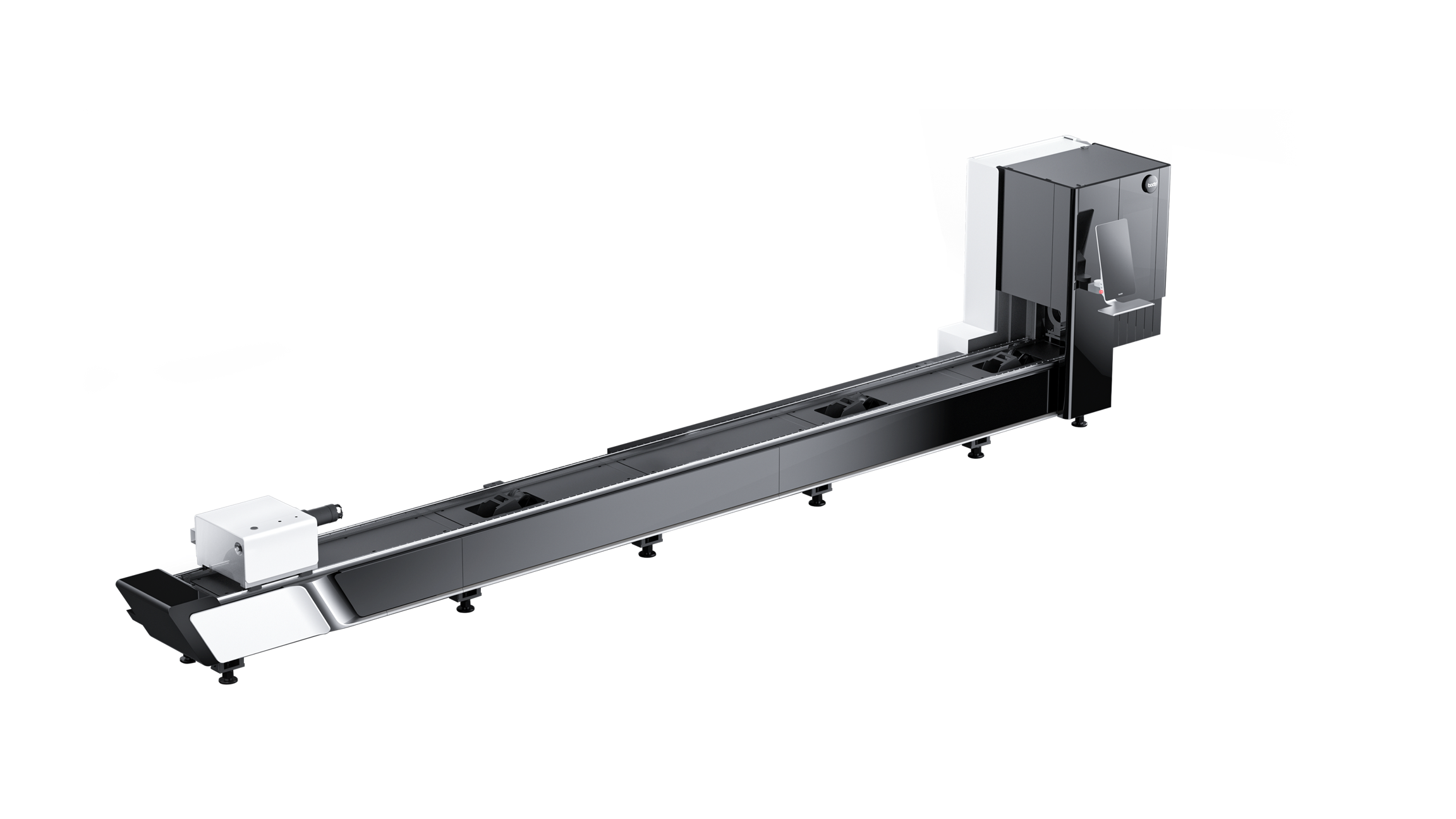

Easy Operation

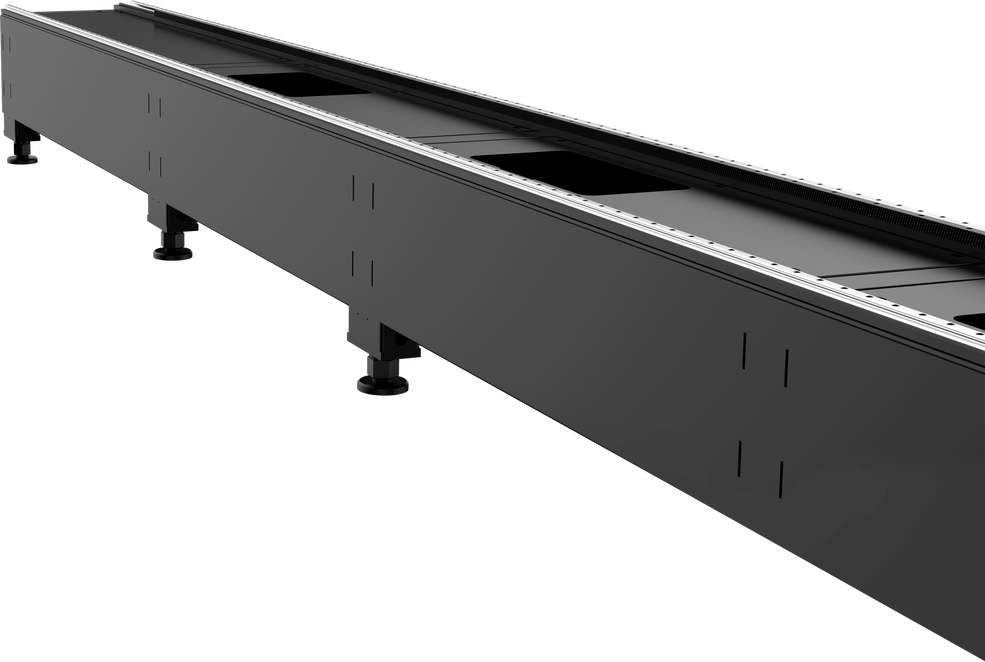

Bodor Laser has launched the K Series laser tube cutting machine to address the issue of high operational barriers in the market. This machine integrates features such as high-speed chucks, fast clamping response in 2S, ultra-short tail material, and a one-click start. It is designed to provide a simple, safe, and environmentally friendly tube cutting solution.