Bodor ECO Series Officially Released — Full Power. Lower Costs. Smarter Welding.

Discover Bodor’s ECO Series handheld laser welding machine — combining full-rated power, faster welding speeds, and up to 50% labor cost savings. Smart, efficient, and automation-ready for next-gen manufacturing.

Bodor Laser, a global leader in laser cutting and welding solutions, proudly unveils its latest innovation — the ECO Series Self-Cooling Handheld Laser Welding Machine. Designed to meet the evolving demands of modern manufacturing, the ECO Series offers a perfect balance of power, efficiency, and cost-effectiveness, setting new standards in laser welding technology.

Responding to the Challenges Faced by Global Manufacturers

Rising labor costs, skilled labor shortages, and the growing demand for flexible and efficient production have become common challenges for manufacturers worldwide. Bodor's ECO Series answers these challenges, offering full-rated power, simplified operation, and tangible cost-saving advantages.

“At Bodor, we are committed to empowering our customers with intelligent, reliable, and future-ready laser solutions. The ECO Series embodies this commitment by making high-performance welding easier and more economical for manufacturers of all sizes,” said Patrick, Product Manager of Bodor Laser.

Smarter Welding, Tangible Benefits

The ECO Series is designed to deliver superior welding capabilities while minimizing operational costs:

True Full-Rated Power: Achieves deep weld fusion depth and strong joints, even on demanding materials.

Exceptional Welding Speed: Three times faster than traditional MIG or TIG welding on thin sheets, significantly improving production efficiency.

Cost-Effective Operation:

- Consumables cost reduced by up to 25% through nitrogen compatibility

- Labor costs cut by 50% thanks to one-pass welding and simplified operation

- Operators can master the ECO Series within 30 minutes, with no welding certification required.

Versatile Functions: Integrated cutting and cleaning capabilities expand workshop flexibility.

Automation Ready: Equipped with an IO port for seamless integration into automated production lines, meeting the growing trend toward smart manufacturing.

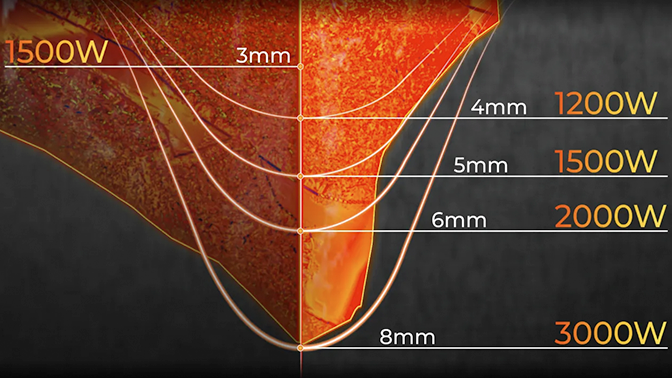

Left: Typical 1500W Welding Depth from Other Brands – 3mm

Right: Bodor ECO 1500W Welding Depth – 5mm

Driving Sustainable and Efficient Manufacturing

The ECO Series goes beyond technical innovation. By reducing material waste, optimizing labor use, and supporting continuous 7×24 operation, it enables manufacturers to achieve sustainable growth while lowering overall production costs.

The ECO Series is now officially available worldwide. To learn more about how it can revolutionize your welding operations, visit the Bodor website or contact your local Bodor representative.

About Bodor Laser

Bodor Laser, founded in 2008, is a globally recognized provider of intelligent laser processing solutions, integrating research and development, production, sales, and service. From 2019 to 2024, the company achieved the world’s No.1 laser cutting machine sales volume for six consecutive years. In 2024, Bodor Laser ranked 17th in the global machine tool industry TOP list. Bodor has a workforce of over 3,000 employees and provides services to more than 180 countries and regions worldwide.