Compact Innovations, Big Impact: Bodor’s Vision for the Future Unveiled at JIMTOF 2024

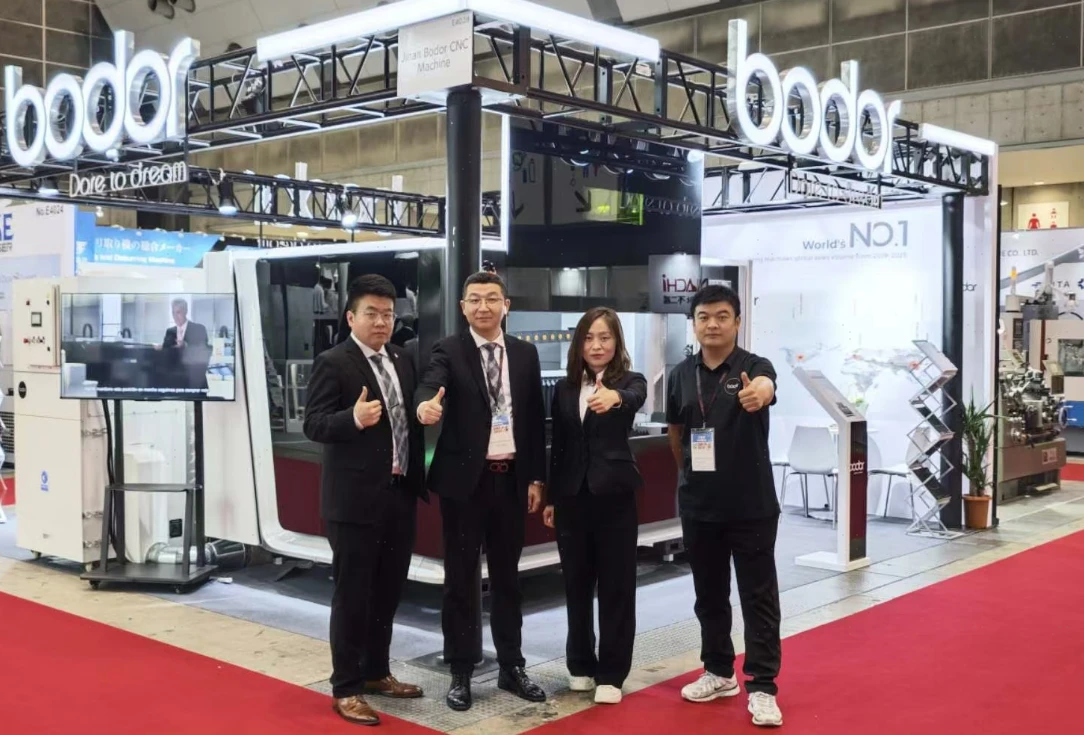

Tokyo, Japan –JIMTOF, one of the world’s premier machine tool exhibitions, returned to Tokyo Big Sight from November 5-10, drawing global leaders, innovators, and manufacturers to witness the latest advancements in machine tool technology. Bodor introduced a compact yet powerful world of laser innovation to the manufacturing industry in this space of possibility. Located in East Hall 4, Bodor’s Booth E4028 quickly became a focal point, drawing in visitors with its high-performance solutions and advanced approach to meeting the evolving needs of modern production.

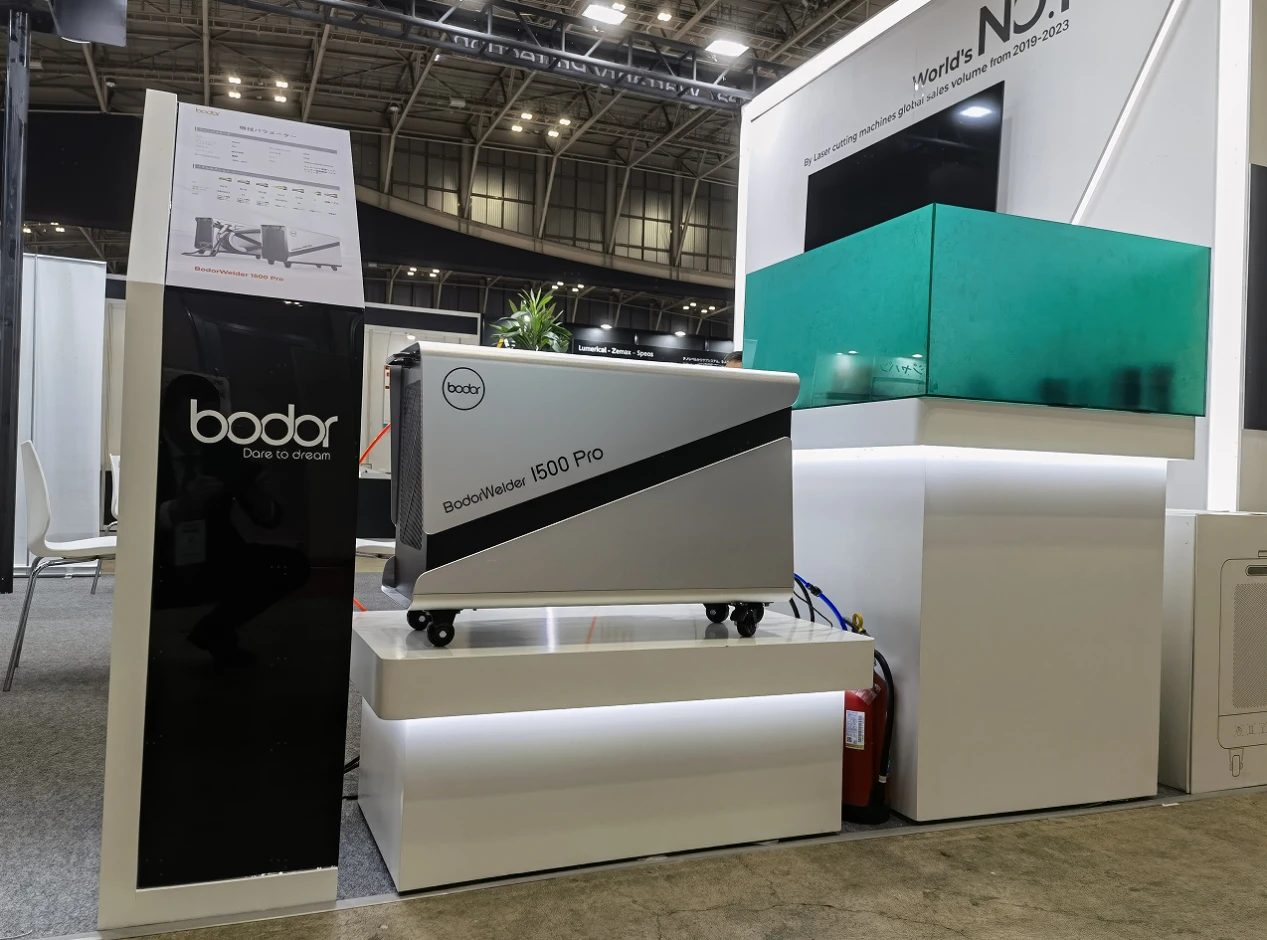

Rising demand for continuous production capabilities, safer work environments, and the need for precise, high-quality parts are fueling growth in the machine tool market. In response, Bodor presented cutting-edge solutions designed to meet these evolving industry requirements. The focal point of Bodor’s exhibit was the Air1200 and Pro1500 handheld laser welders. Equipped with innovative cooling technology, these welders deliver continuous light output even in demanding environments, ensuring reliable performance under extreme conditions. With a simple one-knob operation, the Air1200 and Pro1500 offer a user-friendly experience, allowing operators to manage these smaller yet powerful machines efficiently. Designed to provide professional-grade welding performance in a lightweight, portable form, these solutions are ideally suited for industries such as steel products, automotive and construction.

Accompanying the welding machine was Bodor’s line of versatile, compact cutting solution: the i5 6kW Compact Fiber Laser Cutting Machine. This powerful, compact machine represents Bodor’s dedication to delivering top-tier performance in a space-efficient design. Featuring high-speed, precise cutting capabilities, the i5 demonstrated how manufacturing efficiency and power can be maximized without requiring extensive floor space. Its compact footprint meets the needs of today’s manufacturers who balance production demands with spatial limitations, making it a standout for production facilities looking to optimize space and output.

Accompanying the welding machine was Bodor’s line of versatile, compact cutting solution: the i5 6kW Compact Fiber Laser Cutting Machine. This powerful, compact machine represents Bodor’s dedication to delivering top-tier performance in a space-efficient design. Featuring high-speed, precise cutting capabilities, the i5 demonstrated how manufacturing efficiency and power can be maximized without requiring extensive floor space. Its compact footprint meets the needs of today’s manufacturers who balance production demands with spatial limitations, making it a standout for production facilities looking to optimize space and output.

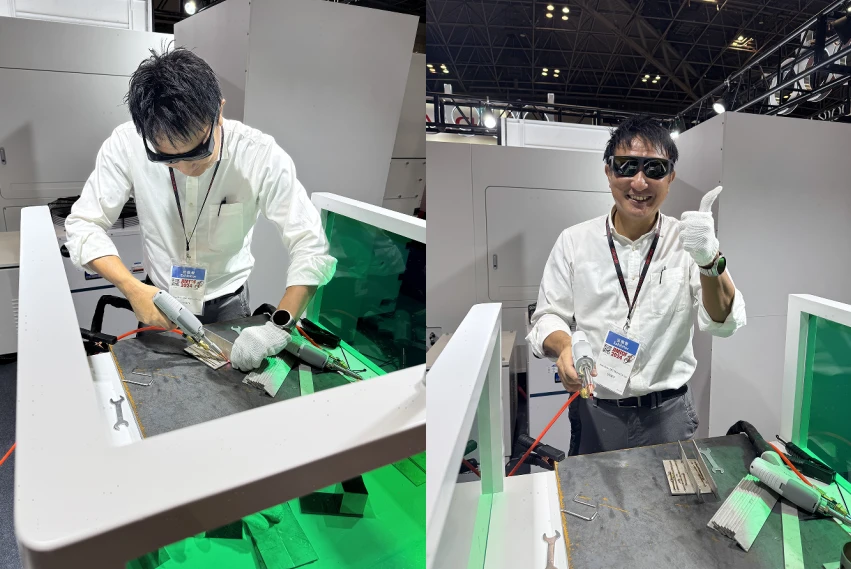

At JIMTOF, Bodor’s booth offered visitors more than just an opportunity to view products. Attendees were invited to experience Bodor technology firsthand through live, interactive demonstrations of Bodor’s advanced cutting and welding solutions. This immersive setup allowed visitors to test the laser machine themselves, giving them a feel for the intuitive operation and precision that Bodor prioritizes in its user-centered designs. The hands-on experience underscored the company’s focus on creating accessible, easy-to-use solutions that empower manufacturers to achieve high-quality results efficiently. Bodor’s commitment to user-friendly technology resonated with professionals across industries, reinforcing the company’s reputation for practical innovation.

At JIMTOF, Bodor’s booth offered visitors more than just an opportunity to view products. Attendees were invited to experience Bodor technology firsthand through live, interactive demonstrations of Bodor’s advanced cutting and welding solutions. This immersive setup allowed visitors to test the laser machine themselves, giving them a feel for the intuitive operation and precision that Bodor prioritizes in its user-centered designs. The hands-on experience underscored the company’s focus on creating accessible, easy-to-use solutions that empower manufacturers to achieve high-quality results efficiently. Bodor’s commitment to user-friendly technology resonated with professionals across industries, reinforcing the company’s reputation for practical innovation.

Attendees especially expressed appreciation for the welders’ ergonomic design, which reduces operator fatigue, and for the machines’ ability to consistently produce high-quality welds across various applications. The live demos underscored Bodor’s dedication to creating tools that combine performance with ease of use, empowering manufacturers to achieve precise, professional-grade results without complex setup or operation.

In a world where manufacturers are seeking eco-friendly and efficient technologies, Bodor’s compact designs offer powerful solutions with minimized energy consumption and a reduced environmental footprint. As JIMTOF 2024 concludes, Bodor looks forward to furthering its mission of delivering high-performance laser technology that meets the evolving needs of the global manufacturing community. We thank everyone who visited us at Booth E4028, and we are excited to continue collaborating with industry leaders and partners to drive meaningful change in the manufacturing world.

In a world where manufacturers are seeking eco-friendly and efficient technologies, Bodor’s compact designs offer powerful solutions with minimized energy consumption and a reduced environmental footprint. As JIMTOF 2024 concludes, Bodor looks forward to furthering its mission of delivering high-performance laser technology that meets the evolving needs of the global manufacturing community. We thank everyone who visited us at Booth E4028, and we are excited to continue collaborating with industry leaders and partners to drive meaningful change in the manufacturing world.

About Bodor Japan

Since entering the Japanese market in 2016, Bodor has led among Chinese brands in laser cutting industry sales. The company has established a robust network of professional agents in major cities like Tokyo, Osaka, Nagoya, and their surrounding areas, ensuring prompt on-site technical support and 24/7 online assistance services to our valued customers. Bodor remains committed to R&D, aiming to innovate further in laser cutting and welding technology to serve Japanese customers better. Bodor will continue to deepen its engagement with the Japanese market, advancing intelligent manufacturing upgrades and striving to align more closely with customer values.