Addressing Cost and Quality Challenges Brought About by Outsourcing

A German Metal Fabrication Company Revolutionizes to In-house Production with Bodor’s T2 and P4 Laser Cutting Machines

Tewe GmbH's Success Story

2x

Costs saved

30%

Cut speed surged

2x

Product qualification rate improved

TeWe, located in Bayern, Germany, stands as a distinguished metal fabrication company with a rich legacy spanning two decades. The company boasts two state-of-the-art plants, collectively spanning 2,500 square meters. Serving industries such as mechanical emquipment manufacturing and wind power generation, TeWe has evolved into a pivotal supplier for renowned entities like Siemens. Founded with a commitment to quality and a sense of responsibility, TeWe’s unwavering dedication to excellence positions them as a key player in the global market.

INDUSTRY

Metal Fabrication

INSTALLATION TIME

2019

LOCATION

Bayern, Germany

High cost, unpredictable lead time, and uncontrollable workpiece quality

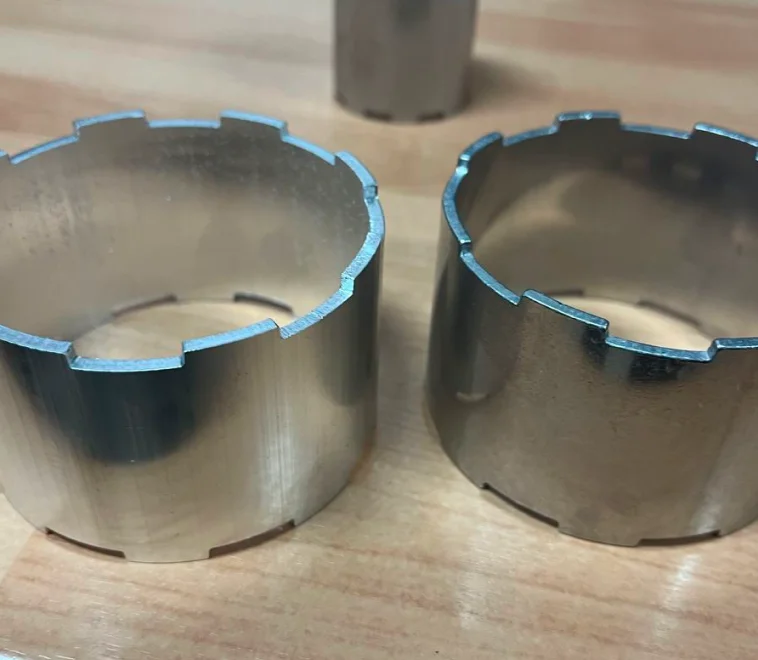

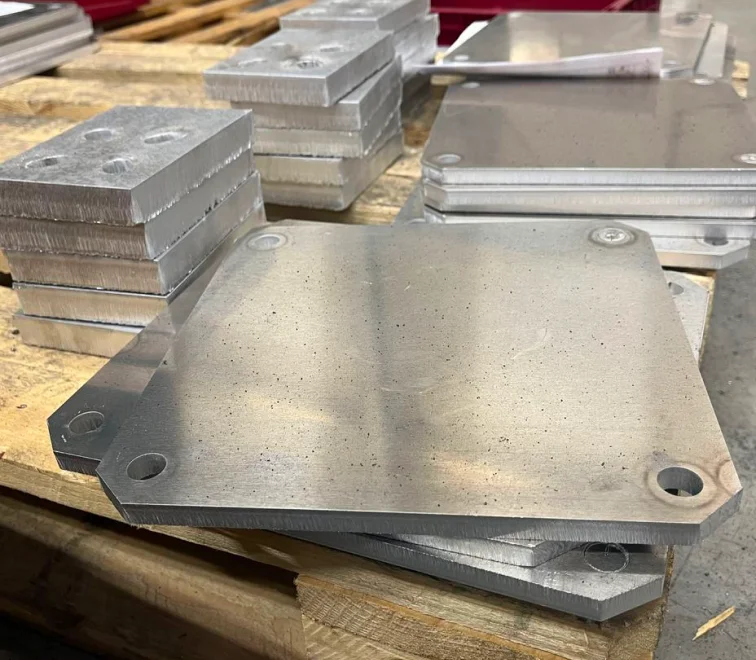

TeWe, which mainly processes carbon steel, stainless steel, and aluminum in thicknesses from 1-15mm and 2.5m wall thickness aluminum tubes, used to face various challenges in processing, including high cost, unpredictable lead time, and uncontrollable workpiece quality.

TeWe outsourced nearly 20,000 parts a year, and the cost of outsourced sheet metal parts remained high, impacting the financial position directly. Besides, engineers faced challenges in ensuring product quality and controlling lead time due to the difficulty in monitoring the production process of outsourced parts. The above issues collectively affected its overall efficiency and competitiveness and became a bottleneck in business operations.

TeWe was inclined to look for automation solutions and decided to purchase a new laser cutting machine. Initially, they received a quote from a German laser company. However, their high price made it financially challenging for suppliers like them who deal with low-value individual parts. As for other European companies, it was tough to visit their machines personally, and most of them lacked local service. None of them could solve TeWe’s problem.

TeWe’s strategic investment: enhancing manufacturing with Bodor laser cutting machines

During an online search, TeWe came across Bodor’s website and was attracted by Bodor laser cutting machines, especially the T Series tube laser cutting machines. These machines are equipped with a number of intelligent functions, such as one-second center searching and lightning piercing, which can effectively address the quality and efficiency challenges TeWe faced. In addition, the exclusive BorderGenius T laser head can make cutting preciser and improve cutting efficiency.

Before long, they witnessed the machines firsthand at an exhibition. To their satisfaction, Bodor machines demonstrated not only efficient cutting speeds but also outstanding performance in material adaptability and precision.

Therefore, after careful consideration, TeWe invested in a Bodor T2 3kW laser tube cutting machine in 2019 and a P4 22kW laser sheet cutting machine three years later. Bodor cutting machines effectively solved TeWe’s difficulties and provided a comprehensive solution to their manufacturing needs.

Half the cost savings and significant improvements in productivity and quality

The utilization of Bodor machines enables the customer to achieve impressive results in efficiency, cost, and quality.

Introducing Bodor’s advanced laser cutting equipment, the cutter is so fast that it can cut a 15mm aluminum part in about 40 seconds, substantially improving production efficiency.

As a result of shifting from outsourcing to in-house cutting, TeWe saves nearly half of its costs, and the quality and lead time of the workpiece processing become controllable. Engineers can better monitor production parameters to ensure product quality, significantly reducing the need for secondary processing. Flexible control over delivery times makes the production schedule more manageable.

Furthermore, the company is impressed by Bodor Laser’s after-sales service, which solves problems for them promptly via instant online communication.