Efficiency Revolution from Traditional CNC Punch Press to Fiber Laser Cutting

A Malaysian Electronics Company’s Journey to Break Through the Productivity Bottleneck with Bodor A3 Laser Cutting Machine

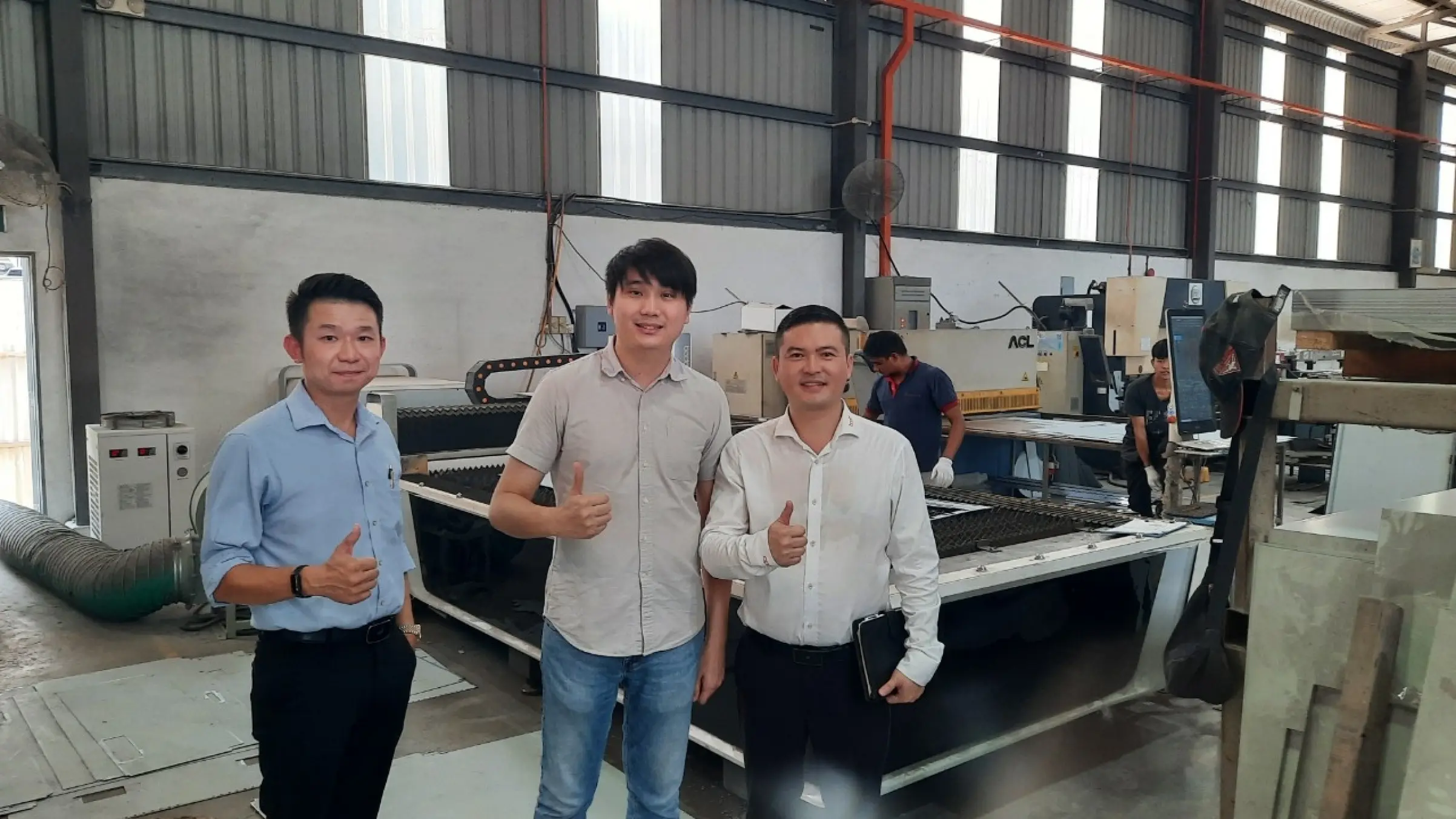

EE-Tech’s Success Story

30%

Order quantity improved

2x

Production efficiency increased

30%

Labor costs saved

EE-Tech, a distinguished Malaysia-based company, boasts over two decades of expertise in the manufacturing industry. The company specializes in designing and manufacturing standard or custom-built switchboards for industrial and commercial buildings and has a leading position in panel technology. Behind EE-Tech’s ascendancy lies the consistent delivery of high-quality and reliable products and services.

INDUSTRY

Electronics

INSTALLATION TIME

March 2022

LOCATION

Penang, Malaysia

Traditional time-consuming CNC punch press hindered the production efficiency of EE-Tech

EE-Tech, a prominent Malaysian company, has established itself as a leader in designing and manufacturing switchboards for industrial and commercial buildings. Despite their success, EE-Tech faced a significant challenge with their production efficiency, relying solely on a single CNC punch press machine.

The utilization of the CNC punch press machine contributed to the low production efficiency experienced by EE-Tech. The CNC punch press may require frequent manual tool changes when processing sheets of different shapes and sizes, leading to time-consuming procedures. Additionally, for intricate shapes and profiles, the CNC punch press may necessitate multiple processes, resulting in lower efficiency. The slow processing speed and inevitable manual interventions led to extended production times and increased labor costs.

The consequences of the low production efficiency were evident in potential dissatisfaction among clients. EE-Tech recognized the pressing need for a more efficient production method to sustain long-term growth and uphold their reputation for delivering high-quality and reliable products.

Revolutionizing efficiency and standards with Bodor A3 3kW laser cutting upgrade

In pursuit of a solution, EE-Tech embarked on a quest to explore advanced manufacturing technologies. The company sought alternatives that could significantly enhance production efficiency, reduce turnaround times, and maintain the high standards of their products.

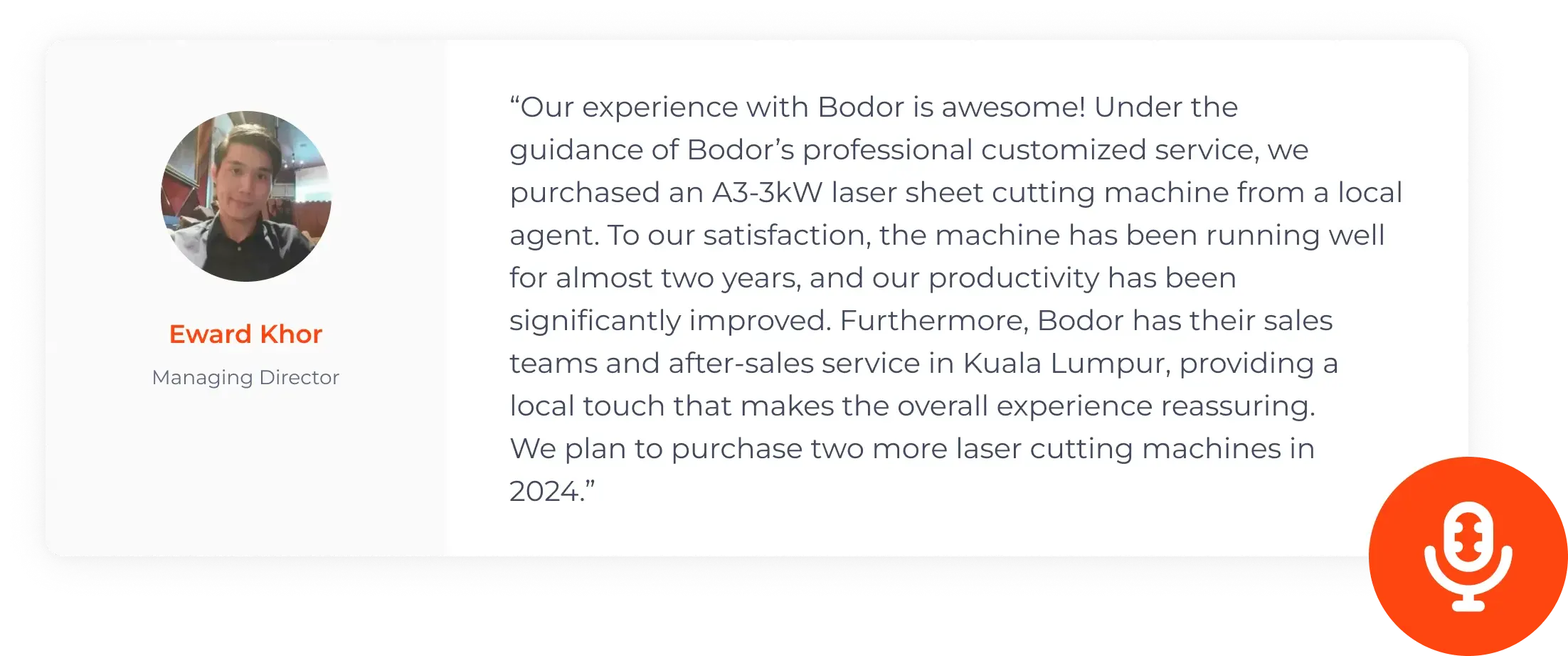

EE-Tech set its sights on the Bodor laser cutting machines, which have gained great acclaim for consecutive years as the top-selling products in the global market, and contacted Bodor Laser's sales team. Through the sales presentation and witnessing the cutting process of the Bodor machines firsthand, EE-Tech found that fiber laser cutting can boast a significantly faster cutting speed, surpassing CNC punching by more than ten times. EE-Tech realized that Bodor Laser could perfectly address their current challenges. Both the outstanding performance of the machines and the professional service provided by the Bodor Laser team left a profound impression on them

After careful consideration and in line with their commitment to excellence, EE-Tech purchased an A3 3kW entry-level sheet fiber laser cutting machine from a local agent. The machine arrived at the factory in March 2022 and was put into operation later that same month.

Farewell to delays, efficiently producing high-quality workpieces with laser technology

Since using the Bodor A3 laser cutting machine, EE-Tech has been relieved of the worry of delivery delays. Thanks to the self-developed BodorPower laser source and BodorGenius laser head, Bodor laser cutting machines prove capable of cutting a wide range of materials with high quality and efficiency. It particularly excels in the efficient cutting of thin metal sheets. The workpieces after laser cuts exhibit a bright and burr-free finish, eliminating the need for secondary polishing and streamlining the workflow. Additionally, Bodor Laser’s self-developed functions such as lightning piercing and active obstacle avoidance can further enhance processing efficiency.

Bodor laser cutting machines’ stable and high-quality operation has empowered EE-Tech to streamline their workflow, leading to increased productivity and reduced production costs. They experience a smoother and faster production cycle, allowing them to fulfill more orders. Now, EE-Tech meets and even exceeds the high standards expected in the competitive manufacturing landscape.