A Revolutionary Change from Plasma Cutters to Efficient Fiber Lasers

Seven Bodor Metal Sheet and Tube Laser Cutting Machines Remarkably Increase Cutting Speed and Thickness

Troimeta's Success Story

7

Number of machine purchased

2x

Cutting thickness rose

6x

Production efficiency surged

Troimeta is a promising Lithuanian manufacturing enterprise that integrates design, engineering, production, and sales for metalwork. With over 100 skilled employees, its business reaches and sells well in North Europe, the Baltic area, Germany, and France. By adopting advanced laser cutting technology for metalwork fabrication, Troimeta has been thriving in the industry with an annual sales revenue of 2 million euros.

INDUSTRY

Metalwork Fabrication

INSTALLATION TIME

2018-2023

LOCATION

Vilnius, Lithuania

Low-productivity plasma tube cutters and incapable-for-complex-work plasma sheet cutters

Various product lines require Troimeta to apply different processing methods. The company used plasma tube cutters to manufacture containers, H-beams, shelves, and bridge parts with diameters ranging from 20mm to 200mm; and used plasma sheet cutters to produce banisters and cupboards with thicknesses from 1mm to 20mm.

However, these two kinds of plasma cutting machines did not make things easier for Troimeta.

The plasma tube cutting machines were inefficient and necessitated human work. For example, Troimeta could only process 50 tubes a day, far lagging behind its production needs. The workers had to drill holes manually since the machines could not create holes in the metals directly.

When processing intricate and complex patterns, the plasma sheet cutting machines created large kerf and evident tapers that compromised the cut quality of metalwork. As a result, the company had to give up many orders which needed elaborate fabrication.

Seven bodor metal sheet and tube laser cutting machines reverse the inefficiency situation

To increase production efficiency and improve product quality, Troimeta determined to turn to laser cutting technology as it exhibits stronger power and capacity than plasma cutting. The company conducted thorough research on many laser cutting brands and spotted Bodor.

The Bodor Team demonstrated the cutting scenes to Troimeta on-site and their excellent cutting samples impressed the company when it was checking the complex design generated by Bodor’s sheet laser cutting machine. The company specifically required to see the performance of Bodor’s tube cutting machine and was amazed by its fast cutting speed and quality.

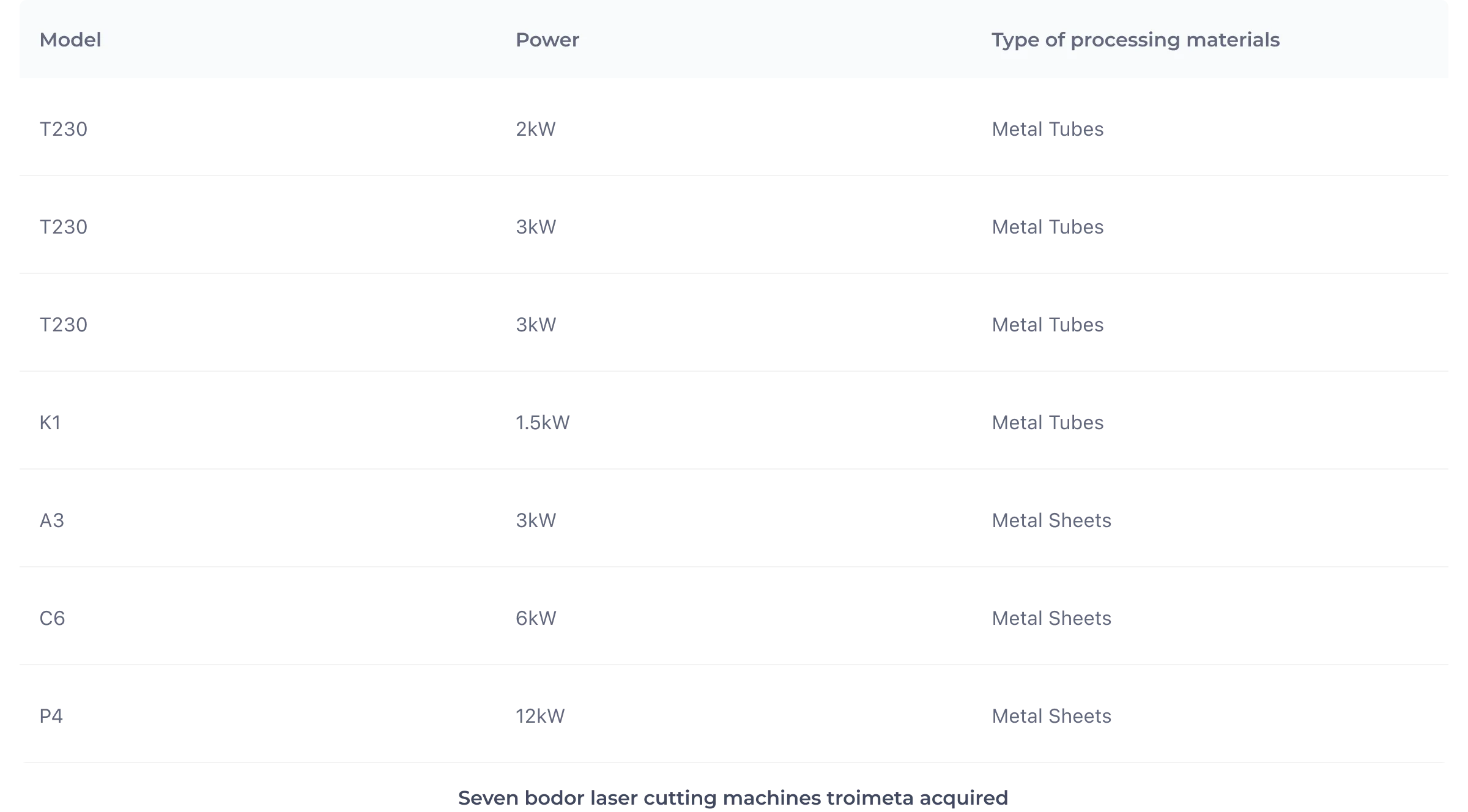

From 2018 to 2023, Troimeta invested in seven Bodor laser cutting machines in succession, covering a diverse product range of metal tube cutting machines and metal sheet cutting machines. The reasons that Troimeta firmly chooses Bodor are not only because of the remarkable capacity of the machines but also due to Bodor’s professional and responsive after-sales service.

Achieving a 6-fold enhancement in tube processing and a 2-fold increase in cutting thickness

Troimeta now has the capacity to process at least 300 tubes a day, efficiently surpassing the plasma’s maximum productivity of 50 tubes. This 6-time enhancement in speed allows the company to receive and finish many more orders in unit time.

By increasing the maximum cutting thickness from 20mm to 40mm, the company is capable of offering metalwork fabrication services to a larger customer base. Moreover, with the advanced Bodor P, C, and A series, it can achieve beautiful and delicate designs on its metalwork, greatly improving customer satisfaction.

The stable machine condition and responsive service provide assuring support to Troimeta to maintain daily operations. Since fiber laser cutting machines do not need to change consumables frequently as plasma cutters do, the company saves operational and labor costs as well.