Revolutionizing a metal fabricating business's in-house production game:

Skyrocketed Productivity And Minimized Lead Time

↓

Assemblik's Success Story

24%

Revenue increased

600

More orders handled in a year

30%

Customer waiting time reduced

Assemblik® , a once modest metal fabrication company, quickly established itself as a reputable local provider of premium-quality laser cutting, bending, and metal welding services across various industries in Queretaro, Mexico.

INDUSTRY

Metal Fabrication

DELIVERY TIME

December 2020

LOCATION

Queretaro, Mexico

Low delivery efficiency despite having a skilled team

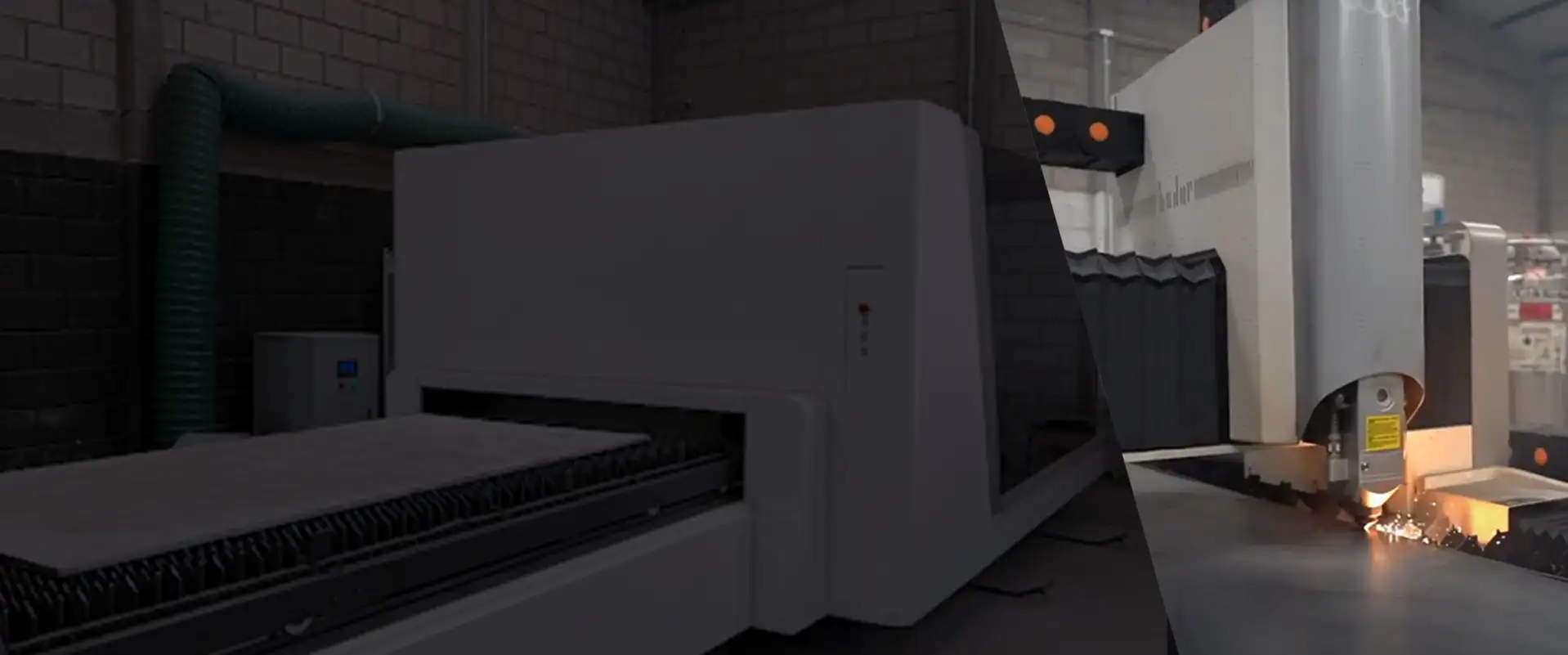

In its early days, despite a strong team consisting of seasoned engineers and designers in industrial manufacturing, Assemblik® struggled to keep up with demand and ensure timely delivery of products due to the lack of in-house laser cutting equipment. Fortunately, the tide turned after the company invested in Bodor Laser's cutting-edge machinery, bringing about a remarkable transformation in the company's business output and customer satisfaction level.

Three Bodor laser machines including a 12kW

After researching available options on the market, Assemblik®'s final decision to invest in Bodor's laser cutting machines was made taking account of positive reviews from industry friends and soon proved to be a game-changer for the company. Assemblik® has since added three different models of Bodor machines - the A3T3 2kW, A3 3kW, and P3 12kW - to their production line, enabling in-house material processing for reduced customer lead time and efficient production with improved quality control.

Our customers have been quick to recognize the improvements we've made.

Particularly impressed with Bodor high power models' capabilities on scaling up its productivity, the general director of Assemblik®, Adrian Alacon shared, “Beforehand, we receive over 1000 projects order a year and the daily working schedule was brimming, the customers have to wait in line for long lead time. ” Within 6 months of introducing Bodor’s machines, the company is capable of handling 800 project orders with ease." Our customers have been quick to recognize the improvements we've made, and that’s a real booster of positive word of mouth for our company and what made us stand out among the other local competitors," he added.

" The development and growth of our company is also the epitome of Bodor's gradual growth in Mexico. I am very happy to have chosen a reliable brand with a reliable group of people. " Adrian commented on the collaborating with Bodor laser. Looking to the future, Assemblik® plans to continue its partnership with Bodor and has already set its sights on investing in a fourth laser cutting equipment.

Efficiency to meet future growth

Winning customer satisfaction

Finding a reliable business partner

Competitiveness in the local market