Upgrading to Lightning-fast Fiber Laser Cutting from Outdated CO2 Cutting

A Polish Metal Furniture Manufacturer Elevates Processing Speed with Two Bodor Machines

Plast Stol's Success Story

3x

Cutting speed soared

60%

Processing efficiency enhanced

50%

Costs saved

Plast Stol is a Polish company specializing in the manufacture of metal furniture. It boasts a vast mechanical complex capable of producing various furniture components and finished products. The company is distinguished by its original designs, aiming at creating personalized interior styles for customers. Plast Stol remains committed to providing customers with high-quality products and professional services, which earns high praise from their business partners.

INDUSTRY

Metal Furniture

INSTALLATION TIME

2019

LOCATION

Czernica, Poland

Slow cutting speed of CO2 cutting led to Plast Stol's productivity bottleneck

Renowned for their expertise in crafting metal furniture with unique, original designs, Plast Stol has long stood at the forefront of the industry. However, their production has hit a bottleneck due to the sluggish processing speed of their CO2 cutting machines.

The CO2 laser source, a specialized gas laser source, operates by stimulating gas molecules within a laser tube to generate a laser beam. While it produces fine cutting seams, its processing speed for thick carbon steel is notably slow. Exacerbated by the limited power of Plast Stol's 4kW CO2 cutting machine, it further constrained cutting rates. This significantly hampered their productivity, resulting in prolonged production cycles for those large furniture and diminishing their competitiveness within the industry.

Moreover, the intricate structure of the CO2 laser source entails high maintenance costs. Additionally, with a photonic conversion efficiency of less than 10%, CO2 laser sources consume considerable electrical energy during operation. These factors exacerbated Plast Stol's financial burdens and hindered long-term company growth.

To break free from this productivity bottleneck, Plast Stol resolved to abandon the outdated CO2 cutting machine and seek more efficient processing methods.

Determined to upgrade equipment: investing in two fiber laser cutting machines

Compared to CO2 laser sources, fiber laser sources stand out for their characteristics of shorter wavelengths, higher energy, and greater conversion rates. The superior energy output of fiber laser sources translates into higher cutting efficiency and precision. Fiber laser cutting machines, at the same power level, boast cutting speeds 2 to 3 times faster than CO2 laser cutting machines, with smoother cutting sections. Additionally, fiber laser cutting machines incur lower maintenance costs, have longer lifespans, and require minimal consumables.

To enhance productivity and maintain its leading position in the industry, Plast Stol made the decision to invest in fiber laser cutting machines. During an online search, they came across Bodor Laser and were impressed by the excellent performance and functions of Bodor machines. Subsequently, Plast Stol reached out to Bodor's local dealer in Poland and received detailed, customized purchasing guidance.

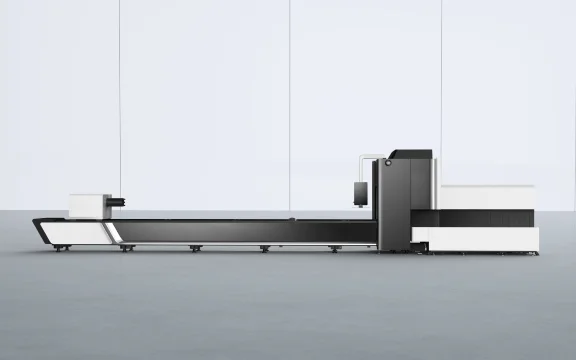

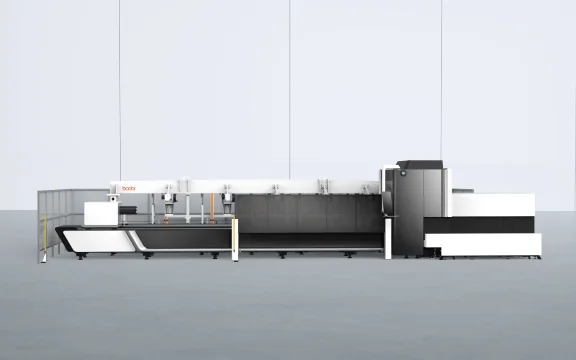

After careful consideration, Plast Stol purchased a P3 6kW and a T2 3kW fiber laser cutting machine, equipping the T2 with T-Trans, Bodor's professional automatic tube loading device.

Enhancing cutting efficiency and reducing costs with Bodor P3 and T2 machines

Embracing cutting-edge processing technology has yielded remarkable results for Plast Stol, with cutting speeds increasing by 300% and processing costs reduced by 50%.

Bodor fiber laser cutting machines boast state-of-the-art components, including the self-innovated BodorGenius laser head and BodorPower laser source. This top-tier hardware ensures not only lightning-fast cutting speeds but also a stable working process. Additionally, Bodor machines come equipped with a range of intelligent functions. From the one-click processing function of the P series to the lightning piercing function of the T series, Bodor machines offer efficiency and precision.

Furthermore, Plast Stol outfits their T2 with T-Trans, Bodor's professional automatic tube loading device, aiming to streamline operations. By seamlessly loading the next tube once the processing of the previous one is complete, T-Trans ensures a continuous and smooth workflow.

The machine upgrade proves to be sensible. Incorporating Bodor's state-of-the-art machines into its operations has not only propelled Plast Stol to new heights of efficiency, but has also fortified its position as an industry leader.