Bodor M

Flagship | Tube Laser Cutting Machine

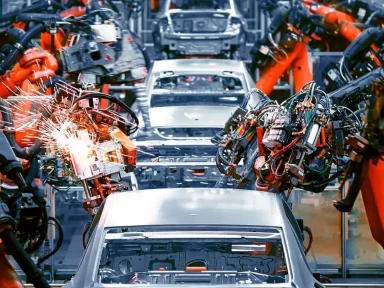

High Efficiency Across Work Scenarios

-

No Manual Intervention

M5’s 4-chuck mechanism enables hands-free, high-precision cutting — no manual intervention needed. This creates a secure, low-cost operating environment, keeping personnel safe and reducing labor expenses.

-

Strong Loading Capacity

Tackle tough metal tube-cutting tasks with ease. M5 handles diameters up to 530 mm, making it ideal for heavy-duty processing and diverse industrial needs.

-

0 Excess Material Waste

Minimize waste from the start. M5 maximizes material utilization during operations, cutting scrap and boosting cost-effectiveness — every piece of material is used to its full potential.