tin tức công ty

Laser cutting/engraving application in feather and textile industry

2017-03-14Laser engraving, a new processing method characterized with high precision, convenience, fast processing, easy operation, high automation and so on, is widely applied in feather and textile industries. Counting in its application in apparel industry, laser technology take a great credit for the development of textile and apparel industry.

Laser engraving embroidery in ready-made clothes

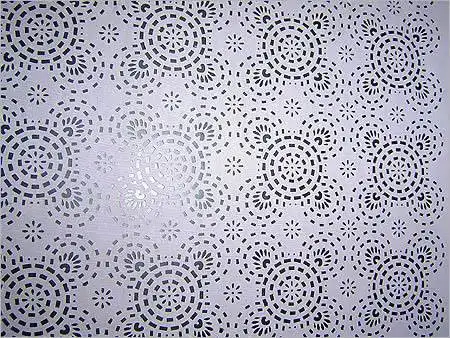

More than two thirds of the textile fabric can be processed with laser engraving machine for digital pattern drawing. Traditional textile processing craft requires post-processing such as grinding, pyrography and pressing, while laser engraving burn-out takes the advantages of convenience, fast-processing, flexible pattern switch, clear image, strong dimensional sense, a fair performance of the texture of different materials as well as a dynamic and evolving development. Combination of laser engraving with hollowing processing brings the final touch to this processing and adds radiance to each other. Application of laser engraving in apparel fabric and ready-made cloth embroidery: cloth fabric deep-processing plant, ready-made apparel factory, apparel fabric and processing trade enterprises.

Laser spray printing for jean contour

The dye in jean’s surface can be vaporized through exposure to laser beam from laser CNC engraving machine, which in turn will imprint images, gradient patterns, cat’s whisker matting effects, adding new charming to jean fashion. Laser engraving jean spraying decoration is a newly emerged, lucrative processing approach with huge potential market. It suits value added deep processing requirement of jean apparel plant, washing plant, manufacturing enterprises as well as family business.

Laser marking processing of feather material

Laser engraving technology is also widely used in shoe making and feather industries. Advantages of laser engraving machine lie in its capability of engraving and hallowing out different patterns in various feather materials. With flexible operation, it will not cause any deformation in feather surface, to highlight feather’s color and texture. It goes further to possess high engraving precision, hollowing without rough selvage, pattern selection without limitation etc., making it suitable for the processing of shoe vamp, shoe accessories, leather ware, cases and bags, apparel and so on.

Laser engraving machine works by connecting the laser equipment with laser engraving software to realize automatic work. At present, laser engraving machine is most mature and widely used technology in laser processing. By taking advantage of this technology, any intricate patterns and images can be processed with this technology. Hollowed engraving and non-pierced blind slot engraving can be carried out for the effect of different engraving depth, textures, contrast in shades, gradient color effect and other magic patterns and images. With this advantages, laser engraving caters to the new trend of international apparel manufacturing.