Bodor Tech Blog

Trending and helpful laser knowledge for your success

5 Irresistible Reasons to Use Handheld Laser Welders

Handheld laser welding is a state-of-the-art welding technology that has recently gained popularity. It offers a range of benefits that make it a more practical and efficient choice over traditional welding methods such as MIG and TIG. Here are five reasons to consider using a handheld laser welder for your next welding project.

Faster welding speed

Handheld laser welding machines are incredibly fast. The concentrated laser beam melts the metal or welding wiremetal almost instantly, and the welds cool down quickly, allowing for rapid production. According to solid research, handheld laser welders can be up to 4 times faster than TIG welding. This speed advantage means you can complete high-volume welding projects in less time and with less labor costs.

Easier learning and operation

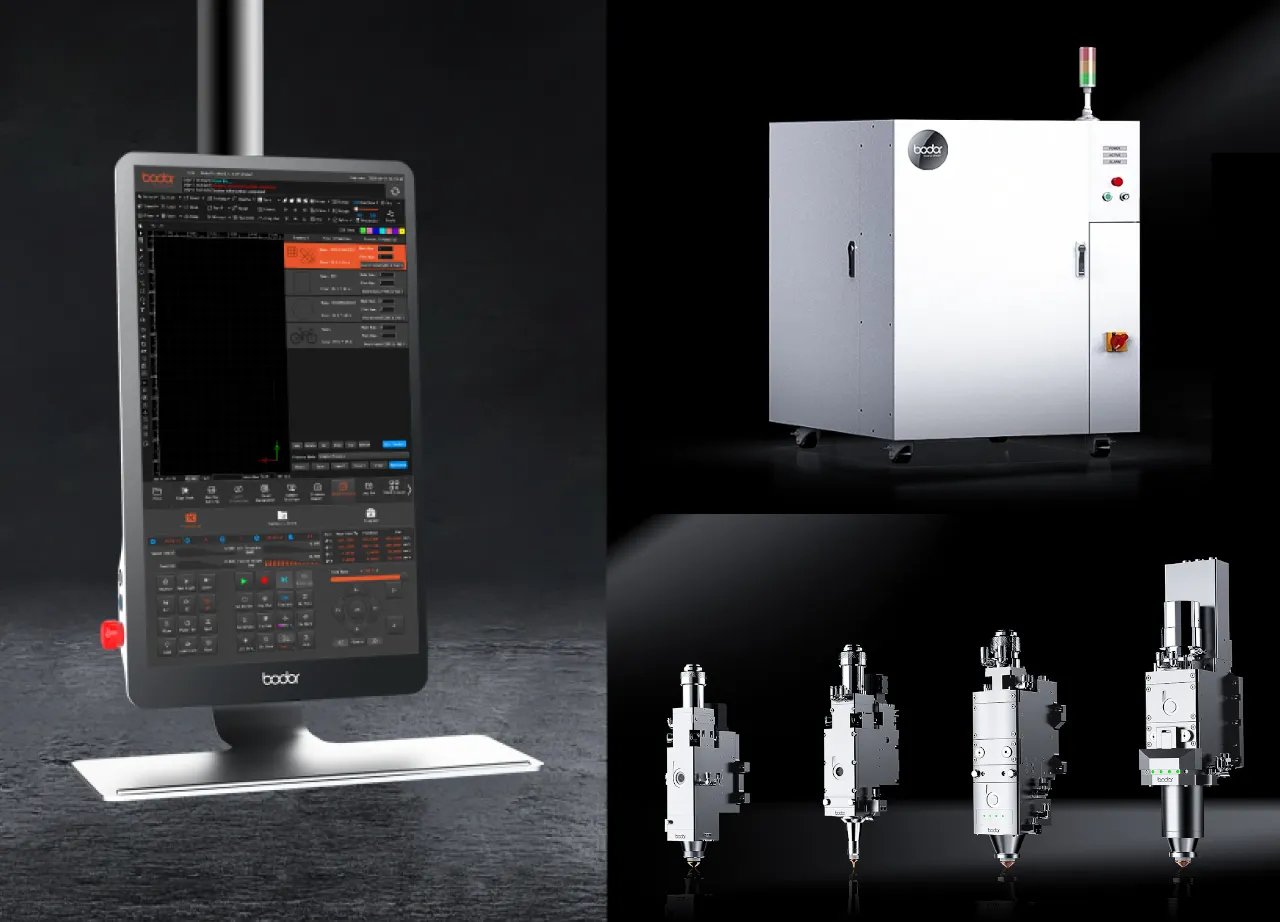

Handheld laser welders are also easier to learn and operate than traditional welding methods. The handheld laser welding machines do not contact the metal directlyrequire any pressure or contact during welding, reducing the risk of operator fatigue and injury. They also have simple and intuitive controls that allow you to adjust the laser power and select the optimal weld settings for various materials and thicknesses. For example, the Pro 1500 , has an intelligent knob control feature that optimizes user processes for users, increasing your capability and flexibility for your welding projects.

Higher welding quality

Another reason to use handheld laser welders is that they can produce higher-quality welds than traditional methods. Handheld laser welders use a high-energy laser beam that melts and fuses the materials together and produces narrow and deep welds free from defects, creating a strong and uniform bond. They also generate minimal distortion, deformation, undercut, or burn-through, resulting in a smooth and aesthetic finish.

Wider material and thickness range

Handheld laser welders can weld metals such as steel, aluminum, copper, and more, with thicknesses ranging from 0.5 mm to 4.0 mm at a laser power of 1500W. They can tackle dissimilar metals challenging for MIG or TIG welding. In addition, theselaser welders can fuse reflective metals like copper and aluminum, which are typically difficult to work with using conventional methods due to their high thermal conductivity and low energy absorption of energy.

| Material | Welding Thickness |

|---|---|

| Carbon Steel | 4mm |

| Stainless Steel | 4mm |

| Aluminum | 4mm |

| Copper | 2mm |

* Material & Thickness Range of Pro 1500

Safer welding process

When using handheld laser welding machines, the chances of fire, explosion, or electric shock are minimal due to the slightest or no absence of consumables, gas and , or electric arc usage during welding. This equipment also has low heat input and a small heat-affected area, which reduces the chances of thermal damage to the workpiece and its surroundings. Additionally, the voltage and current used in these machines are low, lessening the risk of electric shock to both operators and damage to the equipment.

The handheld laser welder is a powerful and versatile tool that improves welding efficiency, quality, and flexibility. If you are looking for a stable, flexible, fast, high-quality, and portable welding solution, you need to check out the Pro 1500 for your welding needs and contact us. We will answer all your questions and provide the most astonishing welding samples anytime.