Bodor Tech Blog

Trending and helpful laser knowledge for your success

Shipbuilding: Exploring Laser Applications and Solutions

Ships represent the most complex, advanced construction an industry produces. Shipbuilding, the process of constructing ships and other floating vessels, typically takes place in specialized facilities called shipyards.

Shipbuilding industry trends

Over the long term, the shipbuilding market is expected to

grow due to increasing seaborne trade and economic growth, rising energy consumption, the

demand for eco-friendly shipping services, and the advent of robotics.

The manufacturing process incorporates a variety of technologies and procedures that require metal cutting or fabrication. Currently, most shipbuilders are applying traditional processing techniques, such as flame and plasma cutting, to produce steel blocks and parts for ships.

However, the mechanical processes with traditional methods

are very labor-intensive as they demand constant maintenance. The cutting processes of flame

and plasma involve cutting fluids that could contaminate soil and water, posing significant

threats to the environment. The limitations have made the shipbuilding production line more

complicated, and as a result, many manufacturers are now seeking better alternatives.

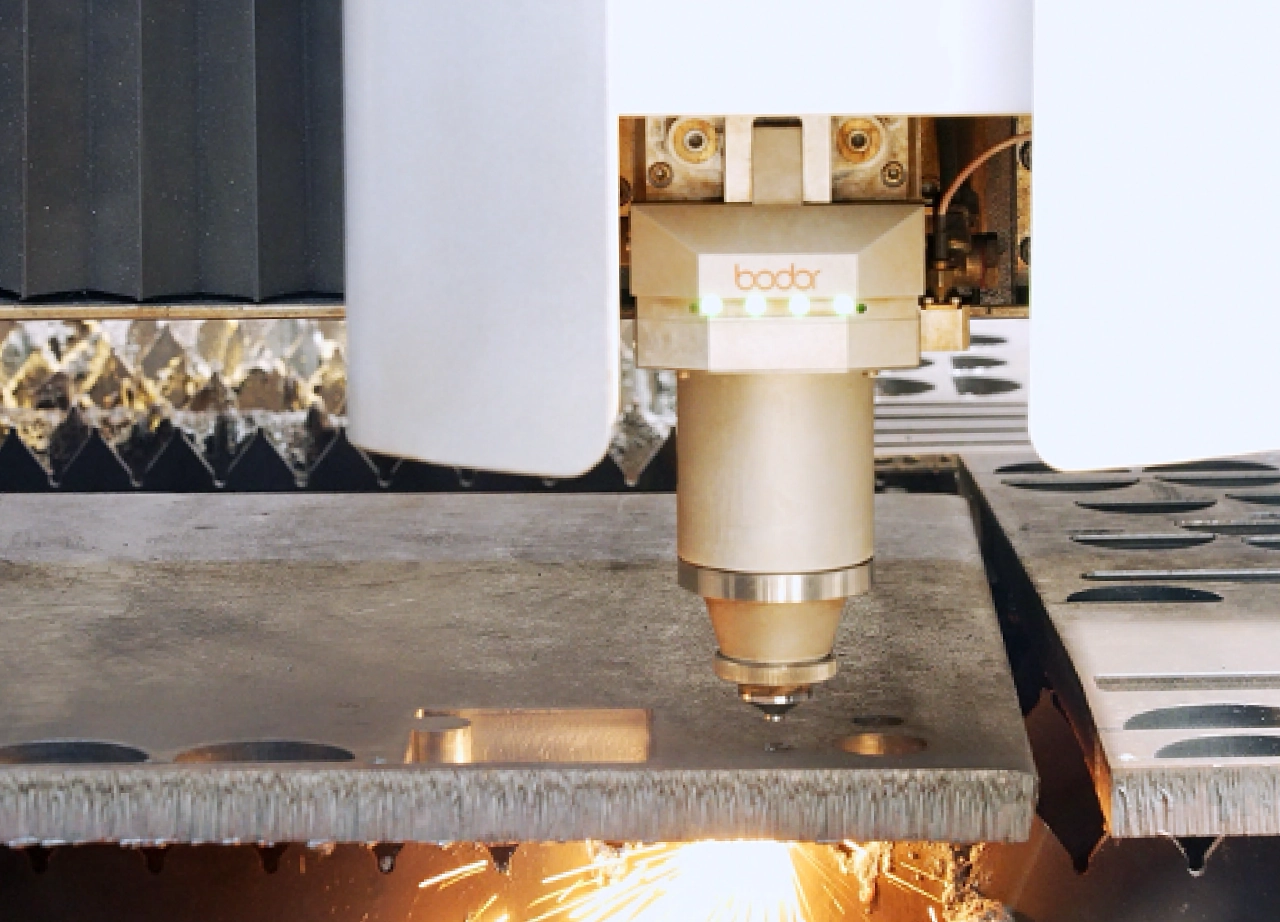

Laser application in shipbuilding

When compared to flame or plasma cutting, laser machines have exhibited many advantages in aspects of production quality, efficiency, and sustainability.

When it comes to metal processing, lasers utilize a

precise, high-density beam for scanning and tracking. The beam increases the temperature in

the scanning area, inducing a formation in the metal material.

This non-contact processing method eliminates the risks of

damage to the surface, resulting in clean and straight cuts with minimal taper and heat

deformation.

Besides the quality presented, lasers are able to cut

faster for much lower operating costs. Meanwhile, they are an environmentally conscious

choice as they generate no harmful particles or gases. The inclusion of dust removal

features in laser technology addresses concerns about workshop dust pollution and further

promotes sustainable development.

Laser technology finds applications in shipbuilding,

including the manufacturing of piping systems, keels, stiffeners, and sternposts.

·Ship plate cutting - Through eliminating the need

for secondary processes like edge milling, drilling, handling, and polishing, laser

technology streamlines the entire production line. It is also particularly effective in

cutting small circles and holes, ensuring that the frame assembly clearance is controlled

within a range of 1mm.

·Ship hull framework processing - In order to connect the frames, decks, and bulkheads, the ship structure requires the support of channel steel and angle steel. Laser cutting machines are an excellent choice for fabricating these strong and stable components.

Bodor: The go-to resource for shipbuilding

Bodor aims to provide the right laser solution for

shipbuilding technology. In the manufacture of pipes, valves, side keels, posts, and

other components, the production must be highly reliable and robust.

The company’s goal is to meet the increasing demands

of shipbuilding construction and processing. Switching could largely reduce your energy

costs in metal fabrication.

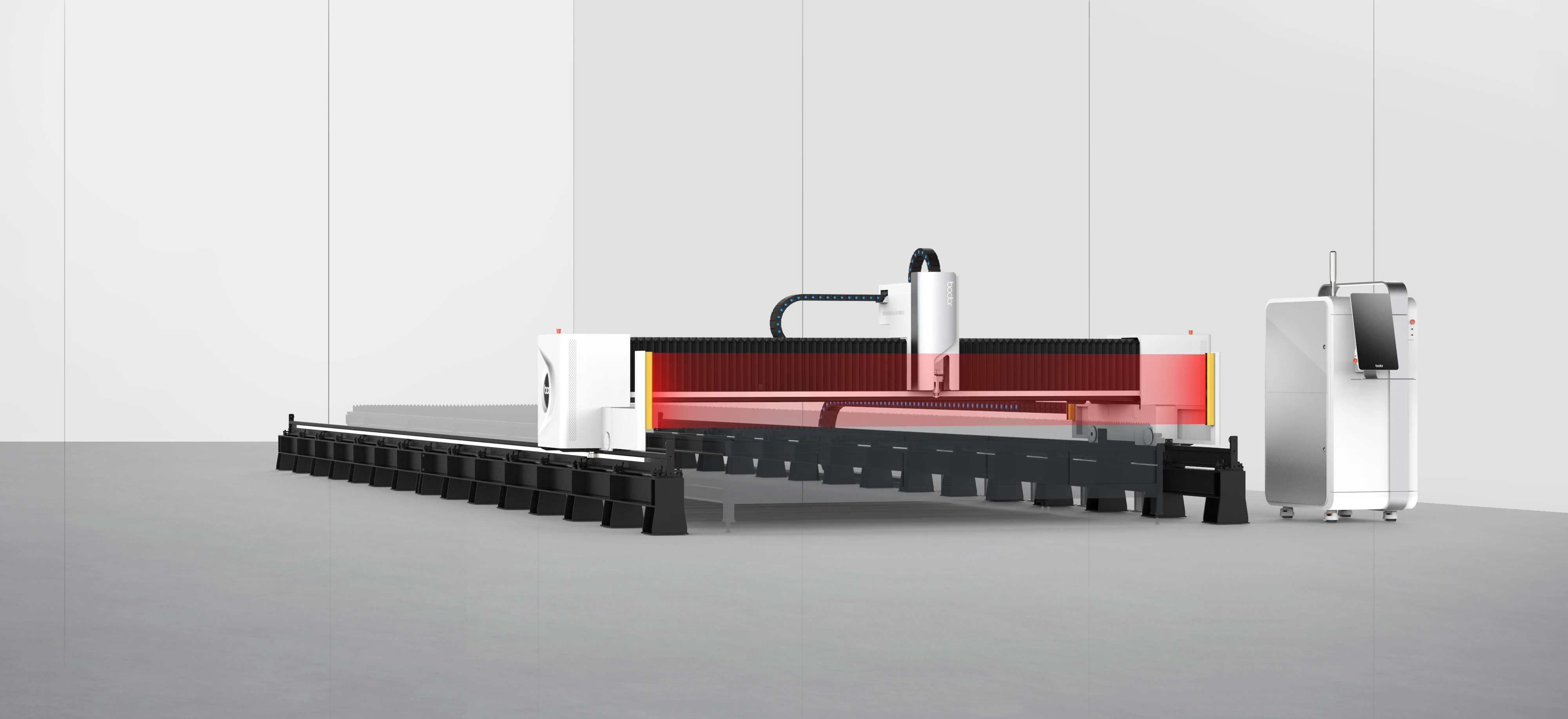

Specifically, for sheet metal processing, Bodor G Series and H Series

are ideal for large format cutting as they ensure reliable series production with maximum precision.

(Bodor G12)

(Bodor H Series)

As for tube processing, discover Bodor M Series laser cutting machine along with its intelligent

features. Equipped with 4 chucks, this high-end product produces quality cuts and utilizes

every piece of material to the largest extent possible.

(Bodor M2, 4 chucks)

If you are interested in any of Bodor’s laser solutions for shipbuilding, please contact us or download our shipbuilding whitepaper. Whether you are looking to enhance efficiency, precision, or productivity in ship construction, our team is available to present you detailed information and answer any questions you may have regarding Bodor laser technologies.