The Brazilian Agricultural Machinery Manufacturer Boosts

Precision and Production Efficiency with Bodor Laser, Achieving 30% Cutting Efficiency Improvement

CSC2000's Success Story

30%

Cutting efficiency

CSC2000, a leading agricultural machinery manufacturer in Minas Gerais, Brazil, has transformed its production processes by upgrading to Bodor's cutting-edge laser technology. Through the adoption of Bodor's A3 3kW scanning fiber laser cutting machine and subsequent purchase of the K2 3kW fiber laser tube cutting machine, CSC2000 has significantly improved both the speed and precision of its operations, leading to greater efficiency and superior product quality.

INDUSTRY

Agricultural machines manufacturing

INSTALLATION TIME

2023/07

LOCATION

Minas Gerais

The Challenges

Materials:

Thin sheet metal for agricultural machinery parts Tubes for structural frames

Business Requirements:

● Need: Higher precision in cutting and faster production speeds to meet increasing market

demand.

● Issue: The plasma cutting technology lacked the necessary precision and speed for thin sheet

metal, leading to rework, production delays, and higher costs.

CSC2000 faced growing challenges in maintaining product quality and speed with their existing plasma cutters. The machines could not achieve the required precision for thin metal cutting, leading to rough, imperfect edges that needed additional work. The slow cutting speed further contributed to bottlenecks in the production line, delaying deliveries and increasing costs. Faced with these issues, CSC2000 needed to find a more advanced cutting solution to meet market demands while improving efficiency and reducing costs.

Bodor's Solutions

Machines in Use:

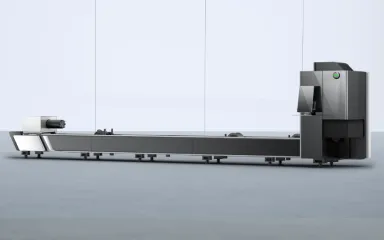

Bodor A3 3kW Fiber Laser Cutting Machine - option scanning cutting function (sheet metal)

Bodor K2 3kW Fiber Laser Tube Cutting Machine (tubes)

Advantages:

● Precision: High-precision cutting for thin sheet metal and tubes, resulting in cleaner edges

and minimal rework.

● Speed: Significantly faster production, reducing bottlenecks and improving order fulfillment

times.

● Cost Savings: Lower operational costs compared to plasma cutting, with reduced maintenance

needs and energy consumption.

● Flexibility: Ability to process both sheets and tubes, enabling CSC2000 to produce a wider

range of components.

● Support: Comprehensive on-site installation, training, and ongoing after-sales support with a

rapid technical response.

CSC2000 first invested the Bodor A3 3kW Scanning Fiber Laser Cutting Machine, designed to handle thin metal sheets with high precision. The machine's advanced scanning cutting function capability allowed for accurate cutting of high reflective materials, greatly reducing the need for secondary processing. Two months later, to enhance their capabilities further, CSC2000 added the Bodor K2 3kW Fiber Laser Tube Cutting Machine. This machine enabled them to cut tubes with equal precision, expanding their production range.

Bodor's dedicated service team in Brazil provided on-site installation and training, ensuring CSC2000's staff could effectively operate the new machines. With Bodor's 24/7 customer support and quick technical response, CSC2000 was able to keep their production running smoothly with minimal downtime.

Results

Since incorporating Bodor's A3 and K2 machines into their production line, CSC2000 has experienced a dramatic improvement in their manufacturing processes. The precision of their cuts improved significantly, allowing for cleaner, burr-free edges that minimized the need for secondary processing. This, in turn, reduced production time and labor costs.

Moreover, the cutting speed saw a substantial increase, enabling CSC2000 to meet client orders faster and with greater reliability. The ability to cut both sheets and tubes with high precision opened up new possibilities for their product range, allowing the company to cater to more complex machinery components. The flexibility and efficiency of Bodor's machines have empowered CSC2000 to serve its customers better and maintain its competitive edge in the agricultural machinery sector.

In addition to improved operational performance, the switch to Bodor's fiber laser machines has also resulted in lower maintenance costs than the previous plasma technology, further contributing to overall cost efficiency.