Bodor Tech Blog

Trending and helpful laser knowledge for your success

The Secret to Self-Cooling Welding Machine: Why Do We Use Refrigerant?

Like most manufacturing tools, laser welders generate heat when in operation and need to be properly cooled to achieve maximum performance. Adequate cooling is essential to maintain the longevity of laser welders, as overheating very likely disrupts everyday welding work and slows down progress.

Seeing an unmet need, Bodor has developed an innovative solution to tackle the challenge. Pro 1500, the latest addition to Bodor’s product line, is a turnkey handheld laser welding machine that self-cools and provides consistent power even in extreme environments. Refrigerant is a critical component in the technology of self-cooling, as it works more efficiently than water or air for cooling.

Why refrigerant?

Technically speaking, the refrigerant cooling method utilizes a closed-loop cycle, absorbing heat from the laser welding machine and transferring it outside. It is good at keeping machinery operations at a stable temperature.

Refrigerant vs. water cooling

Water cooling, also called liquid cooling, is a method of heat removal from components and equipment. Yet, refrigerant is more efficient than the use of water cooling. For one thing, refrigerant requires less energy to evaporate and condense than liquid. While it takes in heat emissions, the refrigerant cools the air before pushing it back out to the system. Refrigerant also has a higher heat capacity than water, meaning that it absorbs more heat than water does under usual circumstances.

For another, refrigerant works much easier in terms of maintenance. The water cooling system requires an extra water tank or a radiator for circulation. Consequently, regular maintenance is indispensable. Users must exchange water frequently to prevent issues like corrosion within the water cooling system. As for refrigerant cooling, the same refrigerant can be recycled repeatedly, lasting for many years without any concerns.

Refrigerant vs. air cooling

Air cooling systems use fans or blowers to dissipate heat that the laser welding machine generates. While cost-effective, air cooling constantly struggles with high-powered laser applications. The circulation of air cooling is often limited by the ambient temperature, making it less suitable for environments with elevated temperatures or humidity levels.

Unlike air cooling, refrigerant is able to eliminate heat dissipation from high-power machinery operations. It enables Pro 1500 to function perfectly in all kinds of working locations, substantially lowering labor costs and investment.

Added benefits

The self-cooling technology has an additional advantage: a more lightweight fabric.

Pro 1500 has a tiny footprint, both physically and ecologically. Without built-in water tanks or fans, its integrated design makes it far more portable than other types of welding machines, bringing in exceptional convenience and flexibility to everyday work.

Furthermore, the refrigerant-cooling mechanism works smoothly with the technology of Constant Temperature Circulation. Combined with this technical patent, Pro 1500 ensures the consistency of laser power 24/7.

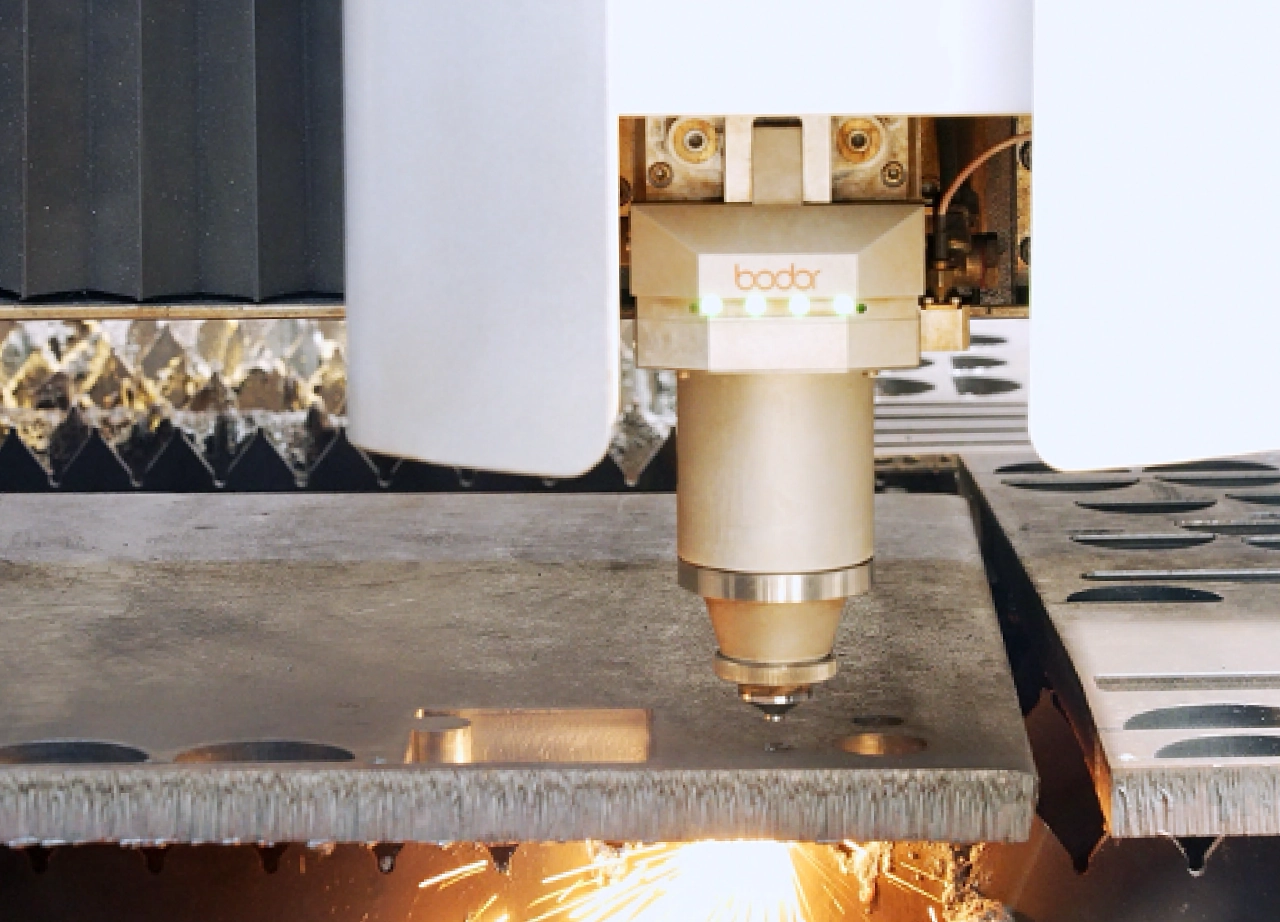

Bodor: a creative laser solution provider

The launch of Pro 1500 marks an incredible milestone that Bodor has successfully stepped into the field of laser welding. If you want to invest in a portable, economical laser welding machine, be sure to contact us for more details. In the meanwhile, we are releasing more information about Pro 1500 as well as its relevant technologies. Follow us on social media and stay tuned for more updates!