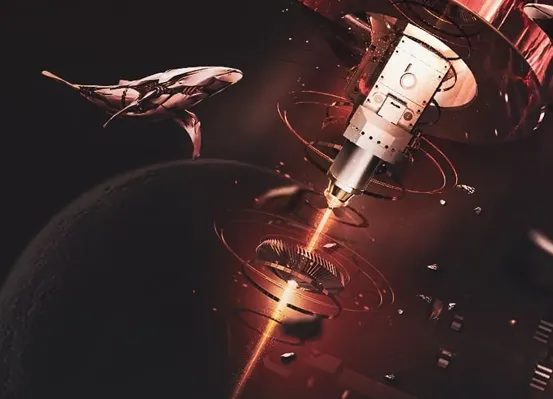

Bodor Laser Launches U10: Multi-tasking Laser Profile Cutting Machine

November 2024 – Bodor Laser introduces the U10 Laser Cutting Machine, an all-in-one system designed to address the evolving needs of modern manufacturing. The U10 combines sheet, tube, and profile processing in one powerful platform, making it an essential tool for industries seeking greater efficiency, reduced costs, and streamlined production workflows.

Filling Market Gaps with the U10

In an era of growing demand for flexible, automated, and efficient machinery, the U10 Laser Cutting Machine fills a crucial gap in the industry. Traditionally, manufacturers needed multiple machines to handle different types of material processing, such as sheets, tubes, and profiles. This approach not only increased equipment costs but also led to longer production times and higher operational complexity.

Bodor Laser saw an opportunity to address these pain points by creating a machine that could manage all three processes within a single platform. The U10 is the result—an all-in-one solution that optimizes production, reduces downtime, and lowers the cost of ownership for manufacturers.

Key Features of the Laser Profile Cutting Machine U10

● Master all types of steel processing

Handles the cutting of plates, tubes, and profiles within one machine (Cutting table is optional).

● Intelligent deviation correction and positioning

Intelligent cutting route adjustment avoids cutting misalignment and reduces laser head collisions, ensuring worry-free profile processing.

● Compatible drawings with Tekla

Compatible with Tekla software, it allows for one-click drawing splitting - no need to use manual and efficient intelligent recognition.

● Locking notch in one operation

By executing lock seam/notch cutting in one pass, the equipment eliminates the need for manual polishing.

● Bevel Cutting

Tubes and plates can be processed with bevels. Its good bevel cutting surface greatly improves the subsequent welding efficiency.

● Flexible Loading for Continuous Processing

For sheets, tubes, and profiles, the zoning of different materials allows continuous cutting, with one area carrying out cutting while others are being loaded and unloaded.

Meeting Today's Demands, Anticipating Tomorrow's Challenges

As a global leader in laser cutting technology, Bodor Laser not only meets current market demands but also actively prepares for future challenges. The U10 goes beyond a simple technical upgrade—it's a forward-looking solution designed to adapt to the growing needs of an ever-evolving industry. By investing heavily in research and development, Bodor Laser continues to push the boundaries of what's possible in laser cutting technology.

The introduction of the U10 reinforces Bodor Laser's position as an innovation leader. The company consistently offers unique, cutting-edge solutions that empower manufacturers with smarter, more efficient technology options.

A Legacy of Innovation

Innovation has always been the driving force behind Bodor Laser's success. The launch of the U10 innovative machine reinforces this commitment, offering a groundbreaking solution for fabricators worldwide. This dedication to innovation has been the cornerstone of Bodor Laser's growth. From its early days to its current status as a global leader, the company has always prioritized research, development, and the delivery of groundbreaking solutions to the industry. With a focus on filling key gaps in the market and understanding the evolving needs of manufacturers, Bodor Laser has set new standards for laser cutting technology.

Through continuous innovation, Bodor Laser has driven industry transformation, giving manufacturers a competitive edge and opening up new growth opportunities.

About Bodor

Founded in 2008, Bodor is an international top-notch intelligent and automated laser cutting and welding solution provider for automobiles, aviation, medical care, electronics, metal processing, and various industries. With more than 2,900 employees worldwide, its service scope spans over 180 countries and regions. The global service centers and engineers provide customers with 24/7 timely support, maintaining long-term and stable partnerships with a variety of manufacturing enterprises.