Bodor's Breakthrough in Independently Developing and Manufacturing Laser Cutting Machines

From Precision Manufacturing to Intelligent Production, A New Era in Laser Cutting

Since its inception, Bodor Laser has been firmly committed to independent innovation. Today, the company has fully developed its laser sources(BodorPower), laser heads(BodorGenius), and operating systems(BodorThinker) — a rare and impressive feat in the field. This technological independence has given Bodor Laser control over every step of the production process, resulting in products that are both cutting-edge and reliable. Customers worldwide are experiencing dramatic improvements in precision and efficiency, thanks to these high-performance laser solutions. Let's explore how Bodor produces its core components in-house.

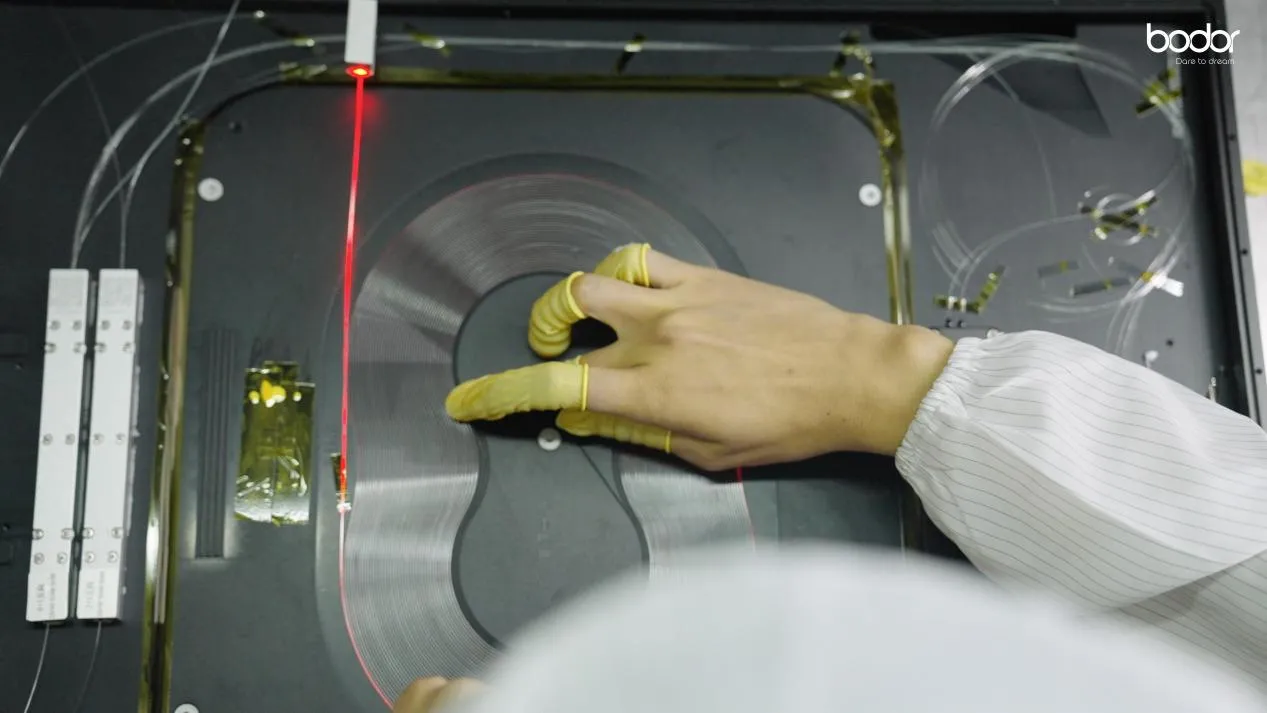

1. Ultra-Clean Precision: Crafting Lasers Like Surgery

Imagine a production environment as clean and controlled as a hospital operating room. That's the level of precision Bodor Laser achieves in its Class 1,000 dust-free clean room and Class 100 dust-free FFU flowbox. It also uses standard and efficient production processes and a strict and complete quality management system to safeguard the production and manufacturing of self-developed laser heads and laser source.

Just like a surgeon performing a delicate procedure, Bodor's production team ensures every component, from the fiber optics to the mechanical elements, is handled with the utmost care.

2. Pushing the Limits with Rigorous Testing

Bodor Laser's commitment to quality doesn't stop at production. Advanced testing equipment meticulously checks the optical paths and beam quality, to ensure the optical fiber has high conductivity. Every laser source undergoes a rigorous 24-hour full-power test before leaving the factory. Only when the hard-core standard of ‘'actual measured power ≥ rated power'' is met can it be packaged and shipped out.

By pushing the limits of quality control, Bodor Laser provides its clients with reliable, Professional Models that are built to last — an essential advantage in industries where downtime and precis

ion are critical.

3. The absolute advantage of independent innovative production

The laser heads and finished lasers are connected and paired in a dust-free manner in the fiber connection room. The integrated production process avoids the problem of component contamination caused by the secondary assembly of laser heads and lasers from different manufacturers and brings stable and consistent product performance. Afterward, the professional application cutting team will uniformly conduct on-machine function debugging and performance inspection. Bodor is committed to bringing product performance to the highest level.

4. Endless Possibilities on the Horizon

Behind the birth of a beam of light is the pursuit of excellence by a group of people. Each production process is equipped with different production management, quality control, response plans, and measures to implement high-standard product quality goals resolutely. The innovative self-developed MES system can realize the visual management and traceability of ultra-clean workshops. In terms of environmental control, the combination of the thousand-level cleanliness management specification and the responsible person system can comprehensively improve the reliability and stability of products.

What’s more, Bodor provides a five-year warranty for laser heads, laser sources, and operating systems based on confidence in product quality. Learn More.

The future of laser cutting is bright — and Bodor Laser is at the forefront of that change, continuously pushing the boundaries of what's possible. With every innovation, the company is paving the way for a new era of manufacturing, where efficiency, intelligence, and precision go hand in hand.

About Bodor

Founded in 2008, Bodor is an international top-notch intelligent and automated laser cutting and welding solution provider for automobiles, aviation, medical care, electronics, metal processing, and various industries. With more than 2,900 employees worldwide, its service scope spans over 180 countries and regions. The global service centers and engineers provide customers with 24/7 timely support, maintaining long-term and stable partnerships with a variety of manufacturing enterprises.