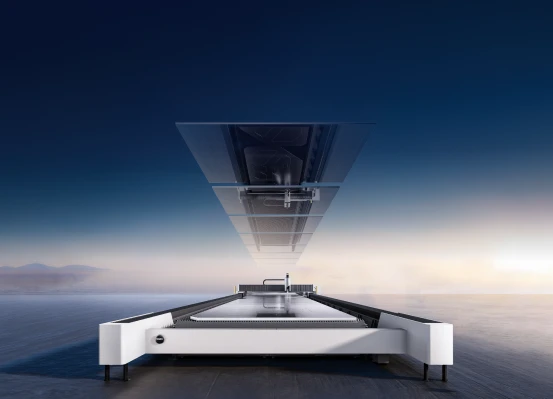

Bodor Unveils Groundbreaking Upgrade to M Series Flagship Fiber Laser Metal Tube Cutting Machine

August 13, 2024 – Bodor, a global leader in the laser industry, is excited to announce the launch of its latest laser technology upgrade: the M series flagship fiber laser cutting machine. Equipped with the revolutionary capability of Dual Process Parallel Processing, the all-new four-chuck laser machine represents a groundbreaking advancement in tube cutting. This technological leap underscores Bodor’s unwavering commitment to delivering cutting-edge solutions that meet the evolving needs of modern production environments.

What is Dual Process Parallel Processing?

Dual Process Parallel Processing allows for simultaneous tube cutting and loading or simultaneous tube cutting and unloading. Specifically, while the C3 and C4 chucks clamp the final workpiece for cutting, the C1 and C2 chucks perform the loading of the next raw material.

[Simultaneous Cutting and Loading]

As the C1 and C2 chucks clamp the tubes for cutting, the C3 and C4 chucks perform the unloading of the previously processed workpiece. Once unloading is complete, the C3 and C4 chucks join the cutting process.

[Simultaneous Cutting and Unloading]

Whether it’s loading new material or unloading the previous batch during cutting operations, the M Series seamlessly integrates these processes to streamline workflows and elevate productivity to unprecedented levels.

Five cutting modes to meet all processing tasks

One of the standout features of the M Series is its Intelligent Cutting Modes Switching system. The five operation modes, 2+0, 2+1, 3+0, 3+1, and 3+1&2+2, are designed to adapt to different tube weights and lengths. The four chucks can automatically switch between these modes, meeting a wide range of operational conditions and requirements.

Whether your operation demands heavy-duty tube processing, high-speed cutting efficiency, or zero-waste material cutting, the M Series handles it all with remarkable precision. This intelligent system gives operators full control over every mode, enabling them to achieve the best possible results in any scenario, making the M Series an incredibly versatile tool for various industrial applications.

Innovative Four-Chuck Design for Zero tube wastes

Equipped with a revolutionary four-chuck structure, the M Series allows for the workpiece to move either forward or backward during the final cut, achieving true zero-tail material cutting with impeccable precision. The four-chuck system also automates the cutting and unloading processes, eliminating the need for manual intervention and significantly reducing safety risks.

Tailored for the Future

As industries face increasing pressure to optimize processes and maintain competitive edges, the new M Series flagship fiber laser is engineered to empower businesses across sectors. This upgrade is exceptionally suited for industries like steel structure, fitness equipment, vehicle manufacturing, machinery construction, agricultural machinery, and oil and gas tubes to handle the complexities of today’s production challenges while offering the flexibility and performance needed to adapt to future demands.

"At Bodor, we understand the challenges that our customers face in today’s fast-paced market," said Adam, the CEO of Bodor’s overseas marketing center. "The upgraded M Series is not just a product, but more a catalyst for transformation, providing the tools necessary to drive growth, efficiency, and innovation across the board."

With years of expertise in laser technology, we continue to invest in groundbreaking technologies and partnerships that will shape the future of tube processing. Our commitment to sustainability, quality, and customer success remains at the core of our operations as we move forward.

The M Series is now ready to order and available worldwide. For additional information on the Bodor M series, please contact our expert sales engineers

About Bodor

Founded in 2008, Bodor is an international top-notch intelligent and automated laser cutting and welding solution provider for automobiles, aviation, medical care, electronics, metal processing, and various industries. With 2900+ employees worldwide, its service scope spans over 180 countries and regions. The global service centers and engineers provide customers with 24/7 timely support, maintaining long-term and stable partnerships with a variety of manufacturing enterprises.