Beyond Cleanliness: The Art and Excellence of Bodor Cable Assembly Standard

Cable assembly that is out of sight in a laser cutting machine is often overlooked due to its technical simplicity. However, Bodor Laser, as the global leading laser equipment manufacturer, sets a meticulous standard for its cable harness assembly. For a number of years, Bodor has been following the spirit of creating revolutionary value for customers and its expertise in laser application technologies has been supported by the commitment to excellence, even in areas that customers might not see.

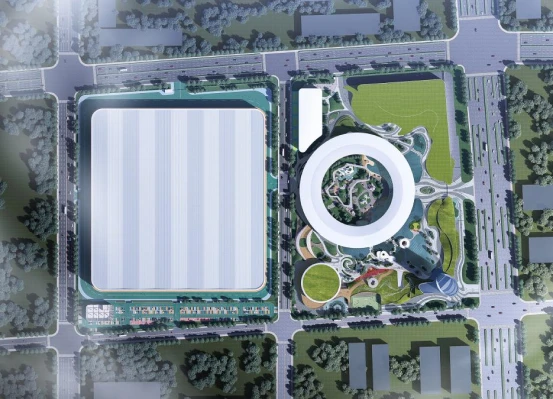

“Veins and nerves” of Bodor laser equipment

Designing the cable assembly process is an important part of modern manufacturing. It takes considerable time and cost and is essential for troubleshooting and maintaining products. Therefore, quality cable assembly directly impacts the reliability, efficiency, and cost-effectiveness of products during their lifespan.

Understanding and researching cable assembly in depth can help optimize the design and manufacturing processes, ultimately enhancing product quality and performance.

Neat and clean cable assembly. Here’s how it’s achieved.

We have meticulous assembly logic and process standards for the cable assembly of laser cutters. Benchmarking against the cable assembly standards of world-class automotive enterprises, Bodor Laser provides specialized Standard Operating Procedures (SOP) and Standard Inspection Procedures (SIP) for each product series. This ensures the completion of cable assembly with the most rational assembly process flow and strict quality control mechanisms, aiming for high-quality and efficient outcomes.

Bodor Laser's cable assembly process combines functionality and artistry. Using topological and hidden wiring technology, standard fixings such as comb plates and cable clamps to fix the cables, ensures the cables are smooth, neat, standardized, and firm. At the same time, considering cable diameter, bending radius, and laying margin factors, the wiring distance and other data are accurately quantified to centimeters. This minimizes problems of movement, wear, twisting, and entanglement caused by tension or pressure on the cables.

Quality management: Bodor’s commitment to excellent quality

In terms of quality management, a production supervision mechanism is established to ensure the standardization and specification of each step in cable assembly through self-inspection, specialized inspection, and final inspection. Quality control is strictly carried out according to acceptance criteria to regulate the overall quality of cable assembly, aiming to achieve a quality goal of "zero defects".

Through lean and integrated cable assembly processes and quality control, Bodor Laser significantly reduces machine failures and safety hazards due to wiring issues, thereby reducing product cost. Based on the result of Bodor Laser's tests, a high-quality cable assembly process can achieve a lifetime maintenance-free rate of up to 98%, placing it at a top-tier level within the industry.

About Bodor Laser

Founded in 2008, Bodor is an international top-notch intelligent and automated laser cutting and welding solution provider for automobiles, aviation, medical care, electronics, metal processing, and various industries. With more than 3,000 employees worldwide, including 20% dedicated to R&D, its service scope spans over 180 countries and regions. The global service centers and engineers provide customers with 24/7 timely support, maintaining long-term and stable partnerships with a variety of manufacturing enterprises.