Bodor laser sets annual sales volume new record in 2022, despite the economic downturn challenges

Bodor Laser announces over 6000+ units of laser cutting machines sold in 2022, setting another annual worldwide sales record, despite the ongoing challenges all over the world due to the economic downturn and supply disruptions.

Over the years since the pandemic outbreak, the laser cutting machine equipment market has taken a hit from the halt in production and end-use sector operation as the import and export activities are greatly impeded. Emerging out of the crisis stronger, Bodor has managed to achieve an impressive 32% compound annual growth rate from 2019 to 2022.This significant sales growth is a testimony to Bodor’s resilience and competitiveness as a prominent player in the global laser cutting equipment market.

Striding into Industry 4.0 with increased investment in technology R&D

The remarkable annual sales success is underpinned by Bodor's practices in ramping up the investment in technological R&D. Between 2016 and 2022, Bodor reported a 30 times increase in R&D investment..In addition, Bodor has expanded its R&D teams outside of China, establishing four overseas R&D centers in Germany, the US, Japan, and India.

In March 2022, pioneering the laser scanning laser cutting technology, Bodor announced the launch of laser scanning cutting machines, which marks a revolutionary technical advance to the existing laser cutting solutions, as well as the creation of a brand new category of CNC laser cutting equipment. Equipped with Bodor self-researched optical system device, optical path space programming technology, and patented processing algorithm, the scanning laser cutting models are recognized for their ultra-high efficiency--- the machines are able to work on an extensive range of materials of more thickness at a higher speed compared with the conventional laser cutters of the same power. This well-received technological innovation troubleshoots the issues of beam reflection during high-reflective metal batch processing.

The rising issues of skilled labor shortage, limited working hours, and labor costs make equipment automation and digitization a key trend in the manufacturing landscape. Plus, the tolls that the pandemic and the global economic downturn take on industrial output is a “wake-up call” for business owners to lean towards cost-effective production by taking advantage of the automated equipment. Keeping up with the trend in the industry, Bodor devised laser cutting machines integrated with automation solutions to optimize performances of loading-unloading, storage, and intelligent sorting of parts. In addition, Bodor develops the MES system, which integrates the functions of equipment management, cost analysis, orders management, and more into one visualization management platform, bringing the conventional workshop into the digitized production era.

Stringent quality assurance approach and customer-oriented services

The other key contributor to Bodor‘s annual sales growth lies in the organization’s stringent quality control system and all-around, responsive services. Equipment quality being the top priority, Bodor ensures each link of the production chain is in compliance with European standards and international quality control requirements, With the certification of CE/ISO9001 serving as the cornerstone, Bodor’s quality assurance approach encompasses 12 inspection procedures including 650°C thermal aging treatment for solidity inspection; 3-axis inspection and positioning to maximize precision, etc. Moreover, Bodor leverages an AI-based Big Data Cloud Center to manage the whole process of equipment production and trace the source; over 2200 monitored links of the production chain record the detailed parameters of the machines to ensure that the data is traceable.

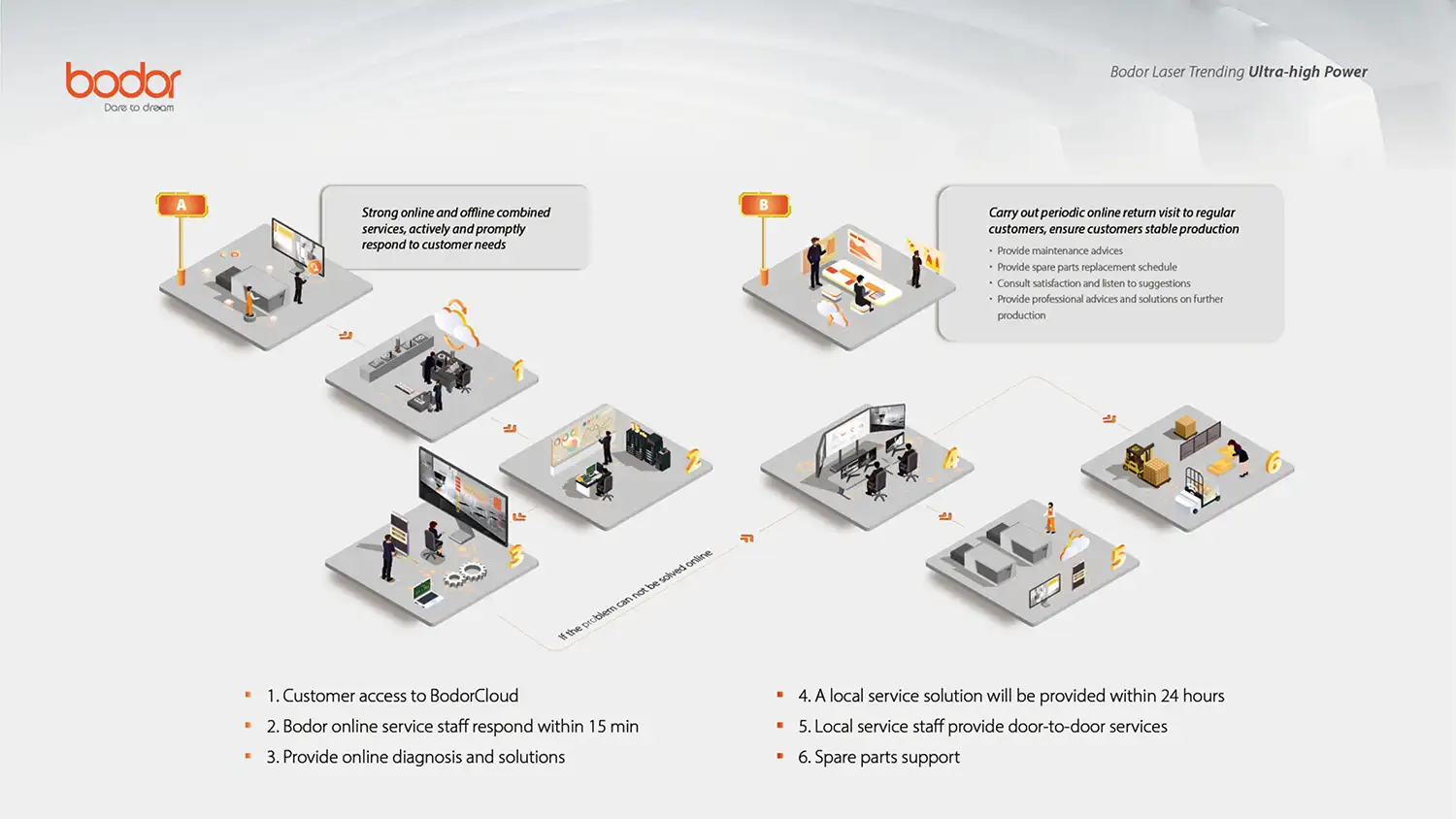

Navigating an increasingly competitive laser cutting market, Bodor believes customer-oriented service makes the organization a distinguishable player today, in long term, and in the future. With more than 180 service networks around the world, Bodor provides 24-hour localized customer support through engineers with years of experience. The application of AI technology is also incorporated in the repair and maintenance solutions, in order to deliver the customer service that is best catered to customers’ individual demands. Bodor service team employs the AI-based cloud service platform for real-time monitoring of the operation status of the sold equipment. Once a malfunction alert based on the real machine operation situation is issued, the service specialists are able to respond to the alert and provide assistance in the most prompt manner.

Looking ahead

As of the end of the first month of the current fiscal year of 2023, the signs continue to point to the market growth of Bodor. Upholding the core mission of changing human lives with laser technology, Bodor will stay at the forefront of technological innovation and change. Moving forward with momentum, the organization is geared up to defy the odds and deliver new record results again in the volatile global market.