Ultra-high Power Laser Will Play A Bigger Role in Various Industries

With the advancement of the "Made in China 2025" strategy, the manufacturing industry in China is transforming into a high-end, intelligent type. Traditional processing technology had difficulties to meet the market's requirements for higher efficiency and higher precision in product production. Laser technology has become an indispensable tool in high-end manufacturing due to its high efficiency, low consumables, small material deformation, and strong adaptability to processing objects. With such a background, high-end laser processing equipment is receiving more and more attention. In current laser processing applications, laser cutting is the most popular application, and fiber laser is the most popular light source system.

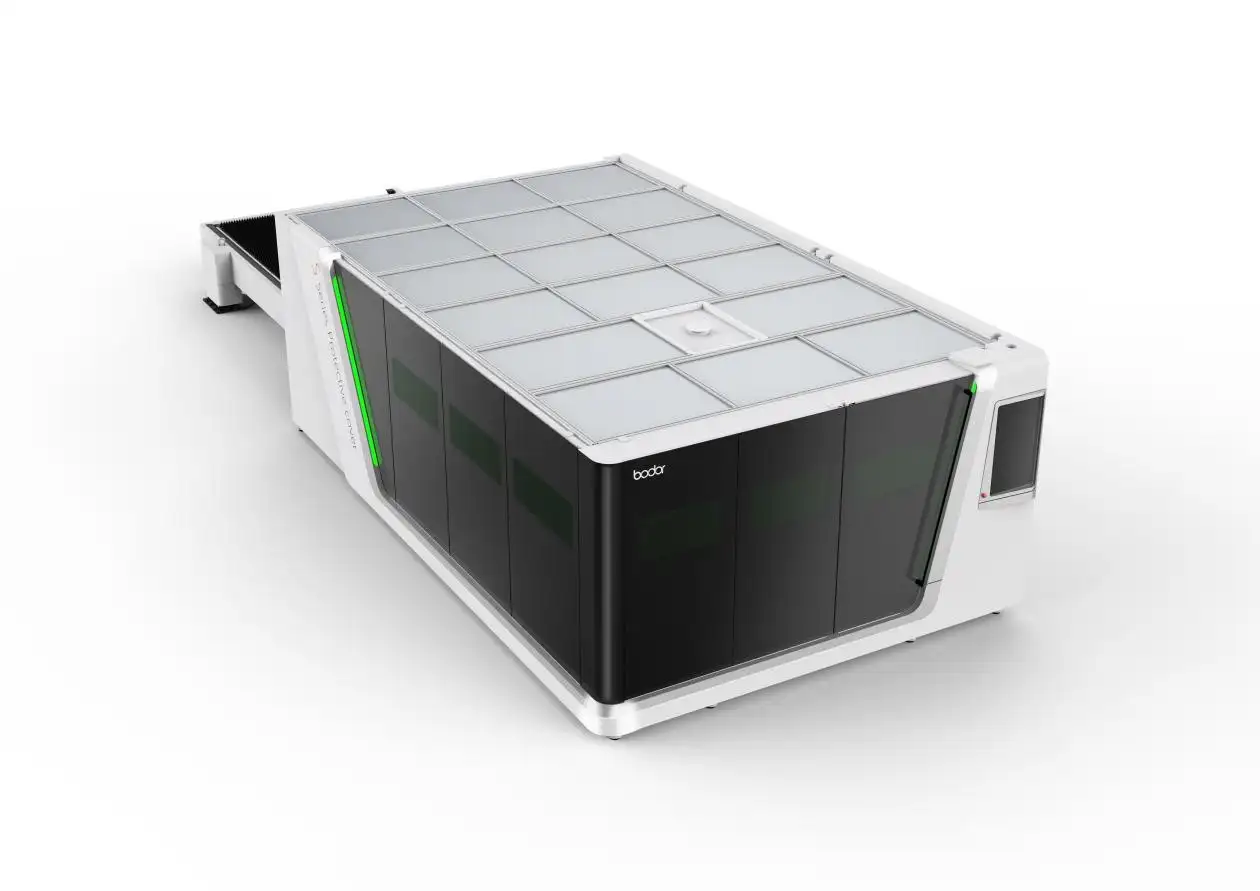

In 2018, the most mentioned words about laser cutting in China is “10 thousand-watt class”. With the substantial increase in the demand for medium and heavy plate processing, there are obvious advantages of ultra-high power laser cutting equipment between medium and small power laser cutting equipment. On the one hand, the efficiency of 10kw cutting equipment is much higher than that of medium and small power. On the other hand, after the power is greatly improved, the cutting process has also undergone a revolutionary upgrade, which ensures the cutting efficiency. It reduces the cost of user processing, and also solves the old problems such as “unstable production of thick carbon steel plates”. It can be considered that although the current 10kw cutting equipment will take a long time to go to the market in large quantities and to the end users, but with the gradual solution of stability and high price problems, the advantages of 10kw cutting equipment will be fully released.

At the Munich CIOE in Shanghai, we witnessed the latest breakthrough in the exploration of high-power domestic lasers. Max Laser has introduced 25000W ultra-high power fiber laser, which is the highest power fiber laser for cutting applications on the market. Its engineers performed a 70mm stainless steel cutting demonstration on site. It showed that the 70mm stainless steel end face was smooth and complete, and the taper was much smaller than the traditional processing techniques such as flame and plasma cutting, which can avoid secondary processing. It can be said that ultra-high power fiber lasers have unique advantages in ultra-thick sheet processing.

At present, the localization rate of high-power fiber lasers higher than 15kw is only 11% with high dependence on foreign imports, so the domestic replacement space is large. Driven by the demand in the shipbuilding industry, metallurgical industry, construction industry, etc., industrial equipment with high-power fiber lasers of 10kw and tens of thousands of watts will play a bigger role in high-end manufacturing applications.