What are the advantages of helical teeth of CNC laser cutting machine over straight teeth

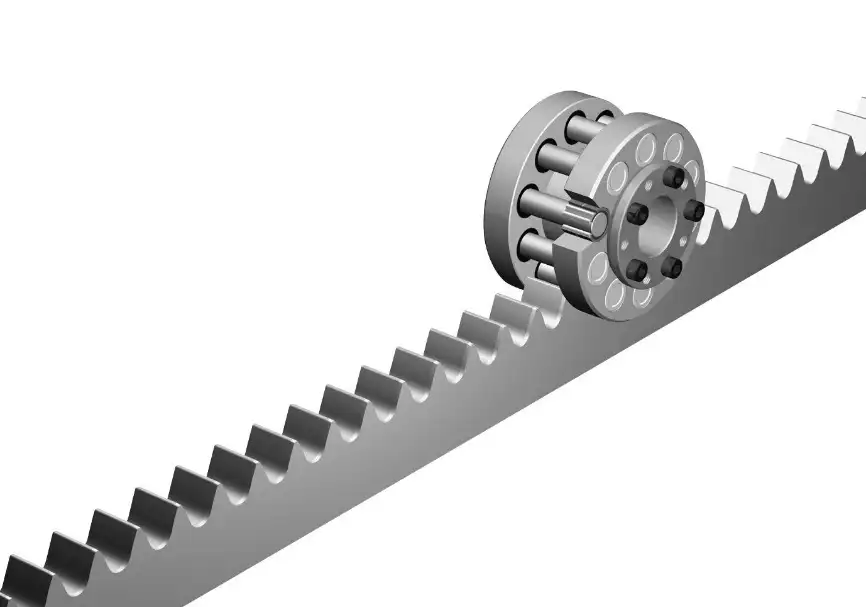

Several types of linear shaft transmission methods commonly used in CNC laser cutting machine tools include ball screws, gear racks, and linear motors. Ball screw drive is often used in low-speed, small-stroke CNC machine tools; rack and pinion drive is widely used to achieve high speed and large stroke; linear motors are mostly used in high-speed, high acceleration, special structure CNC machine tools. In addition, currently commonly used gear racks are divided into straight teeth and helical teeth.

1. Good meshing performance. When the spur gear is engaged, the contact line is a straight line parallel to the axis. Therefore, a pair of tooth profiles enter or exit the mesh at the same time along the tooth width, which is easy to cause shock and noise, and the transmission stability is poor. The contact line of the helical gear teeth is a straight line inclined to the gear axis. When the helical cylindrical gears are engaged, there is a certain limit to the tooth height. Therefore, during the engagement of the two tooth profiles, the length of the contact line gradually increases from zero to a certain position Afterwards, it is gradually shortened until it is disengaged, that is, the helical gear enters and disengages gradually, so the transmission is smooth and the noise is low. At the same time, this meshing method also reduces the impact of manufacturing errors on the transmission.

2. The degree of coincidence is large. The load of each pair of gear teeth can be reduced, thereby relatively increasing the load-bearing capacity of the gear, extending the service life of the gear, and smoothing the transmission.

3. Helical toothed standard gears do not produce undercuts with a minimum number of teeth that are less than straight gears. Therefore, a more compact mechanism can be obtained by using helical gearing.