What leads to the increasing popularity of fiber laser?

The year 2020 is a remarkable one. Not only was our peaceful life broken by the sudden pandemic but also the development of economic was hit by shocking challenges in spite of which the laser industry, running into its turning point of historical development, achieved growth against the downtrend, and especially with the market demands for 10kW+ laser cutting technology being continuously triggered and released, the booming 10kW+ laser cutting machines are becoming a vane in the field of metal processing.

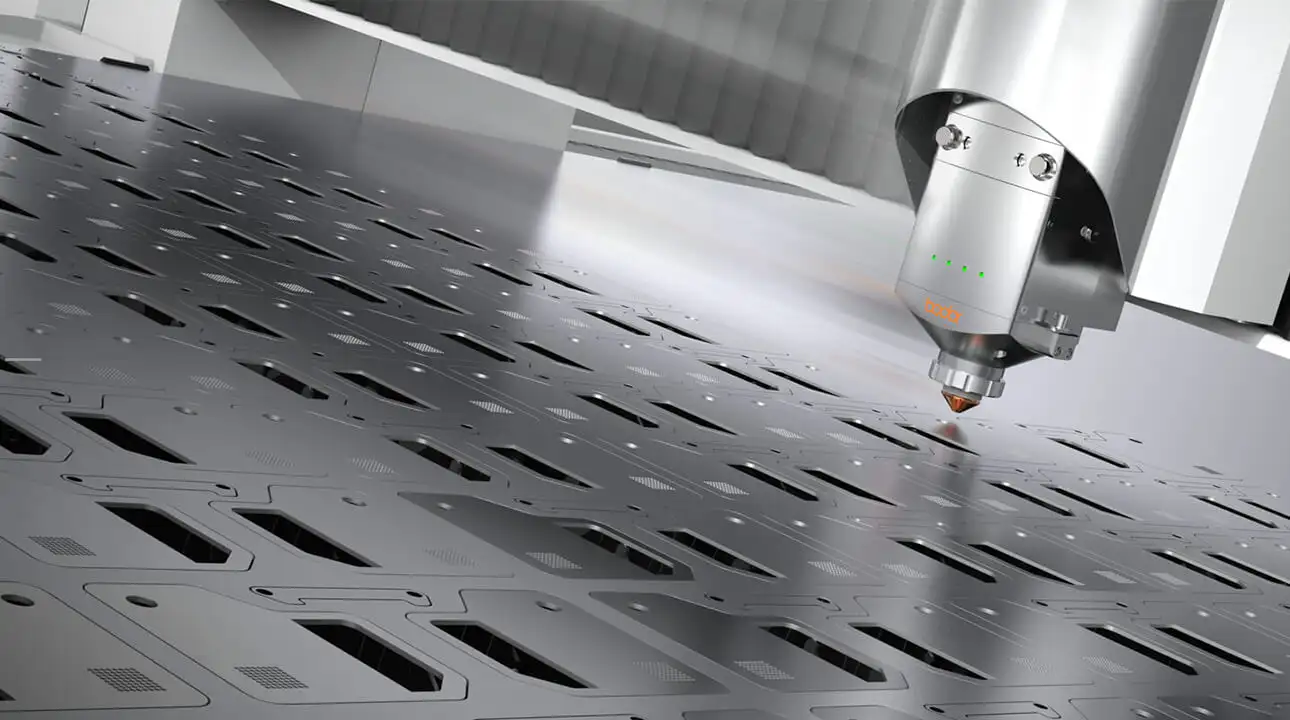

Why do more and more people choose fiber laser cutting machine when it is just one kind of many laser cutting machines in these days when laser cutting is developing rapidly?

Five outstanding advantages of fiber laser cutting machines may answer it:

1. Excellent beam quality: smaller spot size, higher work efficiency and better processing quality;

2. Fast cutting speed: about twice the cutting speed of CO2 laser machine;

3. High performance stability: the stable performance was acquired through the application of world's top fiber laser source which makes it possible to cut at any point with equal quality through fiber transmission.

4. High electro-optical conversion efficiency: fiber laser cutting machine has 3 times higher electro-optical conversion efficiency than CO2 laser cutting machine, saving energy and protecting environment.

5. Low maintenance cost: fiber transmission without using reflective lenses saves a lot of time in optical path adjustment and achieves maintenance-free results.

Cutting below 12mm, especially the high-precision processing of thin plates, is mainly aimed at manufacturers that require extremely high precision and efficiency. With the appearance of high-power lasers, fiber laser cutting machines are replacing most markets of CO2 high-power laser cutting machines.

The intelligent manufacturing process is accelerated and a new business model is created due to the spread of the epidemic, from which the entire manufacturing industry has undergone great changes in a short time. And in the long run, smart production and remote intelligence have shown their advantages continuously, which means intelligentizing is the general trend, now the Strategy of Industry 4.0 is being made by more and more countries, and fiber laser cutting machine fits the trend of production revolution well.