Upgrade Production Scale in the Sheet Metal Fabrication Industry

An Expert Benefiting from Laser Cutting Chooses Bodor C3-12kW Laser to Boost Production of Its New Factory in Florida

The Company's Success Story

3x

Cutting speed rose

50%

Production efficiency boosted

40%

Operational costs reduced

The company is an experienced sheet metal manufacturer with a profound history in Brazil, and it specializes in providing high-quality steel and aluminum sheets for various industries. Committed to excellence and innovation, it has been exploring the strengths of laser technology as an effective tool to branch out. The transnational company now runs two factories in Brazil and expands its business to the United States by establishing a new plant in Florida.

INDUSTRY

Sheet Metal Fabrication

INSTALLATION TIME

February 2022

LOCATION

Florida, U.S.

The Low-efficiency and High-cost German Laser Cutters

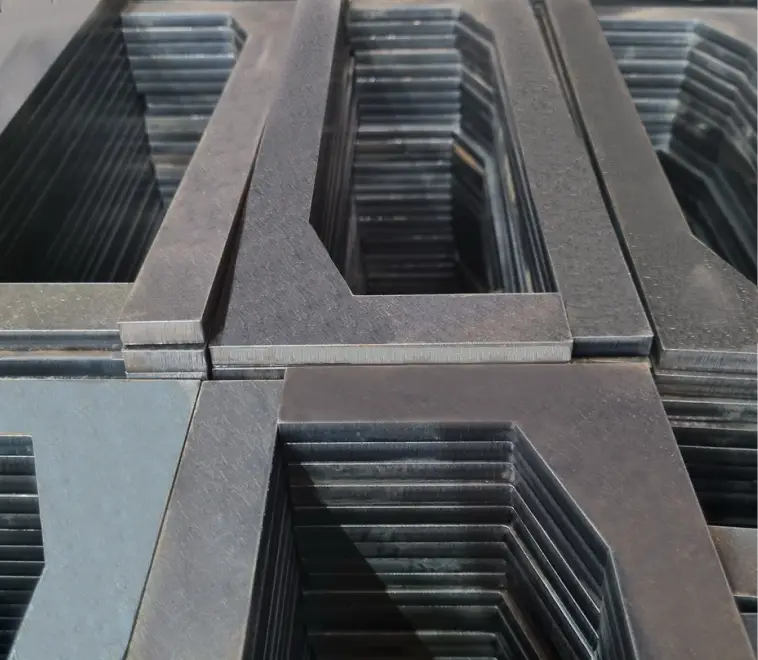

1/16-1/8 inches stainless steel, 1/8-1/4 inches carbon steel, and 1/8-1/4 inches aluminum are the main materials for the company to fabricate. The well-run manufacturer has been adopting laser cutting technology for a long time and is well aware of its strong capacity.

However, the old laser cutters the company used could not cater to its expanding production scale. Low cutting speed only processed limited metal sheets in unit time, extending the lead time and making it lose large-volume or urgent orders.

Another big challenge was that the cutting software of German laser cutters was complicated to use. Operators spent a lot of time figuring out how to use it, and the training program did not offer much help.

Frequently happened inefficient after-sales service troubled the company as well. Because the German service people often did not respond in time, it lengthened the downtime. As a result, operational and communication costs kept increasing.

Bodor C3 - An Efficient Tool for 1/4 Inches of Steel and Aluminum Processing

This experienced metal fabrication enterprise knows how to choose an optimal laser cutting machine based on its experience in laser cutting technology. After observing a Bodor laser cutting machine processing stainless steel sheets, it was amazed by its fast cutting speed and smooth cutting samples.

The company later acquired personalized references and recommendations from a benchmarking customer of Bodor. Those recommendations truly helped the company and made it trust Bodor’s machines and services even better.

To increase cutting speed and production, and save operational costs, the company purchased a Bodor C3 12kw metal sheet laser cutting machine and looked forward to enhancing productivity.

C3-12kW Laser with Air Cutting Boosts Efficiency by 50% and Reduces Costs by 40%

After utilizing the Bodor C3 12kW machine for a while, the company significantly enhanced its cutting speed by 3 times and production efficiency by a remarkable 50%. The company now has the capacity to process 1/16 and 1/8 inches stainless steel sheets with outstanding speeds of 60m/min and 32m/min.

Bodor C3-12kW model also helped the company reduce the operational costs by 40%. Decreased electricity bills and omitted auxiliary gas costs are important reasons. Meanwhile, with more products finished in unit time, the company successfully increases margins and profits.

Moreover, the company is satisfied with the timely and professional after-sales service Bodor Laser Inc., the US branch of Bodor, provides. Throughout North America, the subsidiary delivers fast and reliable services to Bodor laser users, with its 3 local service&tech centers, 4 warehouses, 20+ technicians, and 15,000 ft2 showroom space. Skilled engineers from the service team assist the company in installing the machine, adjusting the cutting parameters based on its cutting needs, and putting it into production promptly.

Provide the Metal Tube Fabrication Service with Bodor’s Laser Tube Cutters

The company sees amazing changes and improvements after using the C3 model and has started considering enlarging its business scope. It plans to acquire a Bodor metal tube laser cutting machine to provide high-quality tube manufacturing services, increasing revenues by catering to a wider customer base.