The advantages of fiber laser cutting machines in cutting carbon steel

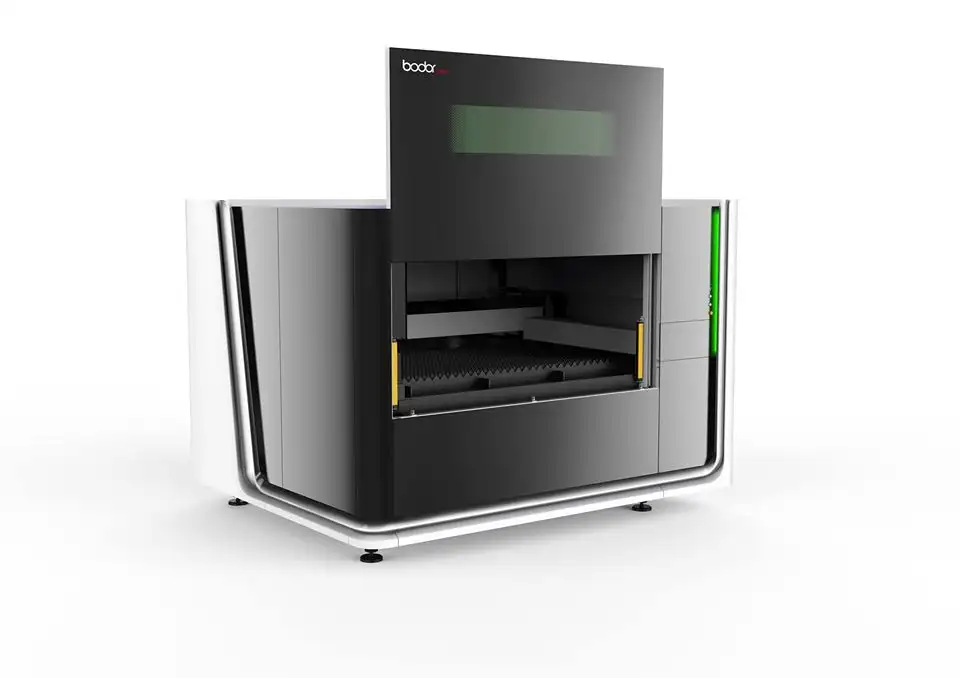

At present, fiber laser users care the most about how to improve efficiency and lower cost, fiber laser cutting machines, with desirable cutting speed, much less deformation and high precision, become mainstream cutting products in a very short time. High-power laser source greatly improves the processing efficiency, the speed of thin sheet cutting has been close to the control limit of machinery performance, and thick sheet cutting also sees a lot of breakthroughs.

Carbon steel is an alloy formed by iron and carbon, and carbon makes around 0.02%-2.11% of its total mass, there are also elements such as silicon, manganese, sulfur and phosphorus in carbon steel. In theory, more carbon brings higher hardness and strength but lower plasticity.

The advantages of fiber laser cutting machines in cutting carbon steel lie in many aspects. Firstly, the cutting quality is desirable, cutting surface is smooth, and there is no need for re-process. Secondly, the cutting speed is fast, greatly improving working efficiency. Then, the output power is stable, and laser source has long service life and easy maintenance. And the strong software function is another advantage. With the software, users can design all sorts of graphics and words, and the software is easy to operate.

For carbon steel processing, the most important part is to ensure the precision, especially for hardware parts which are used on automobiles, ships, precision accessories and home appliances. And the low cost and high efficiency are also key factors. The labor force is getting smaller, automation and smart devices are gradually becoming mainstream, so the laser equipment which can save manual labor and improve efficiency will definitely win the spotlight of the market.