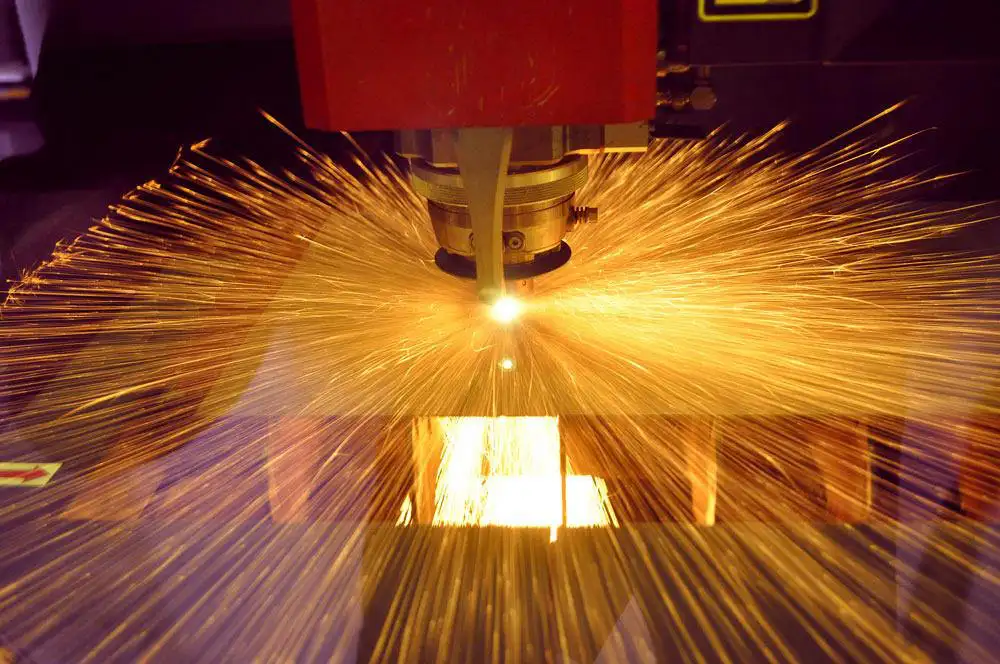

The Application of Laser Cutting in Shipbuilding Industry

In recent years, laser cutting technology saw a fast development in shipbuilding industry. Steel sheets are the main material for shipbuilding, and laser cutting can replace some die cutting methods using complex large mold, greatly reducing production time and lowering costs.

At present, the main unloading methods for hull sheets are flame cutting, plasma cutting, shearing and laser cutting. Compared with other methods, laser cutting has a lot of advantages. When unloading rib sheets using plasma, trimming margin is set to ensure assembly space, and the trimming is carried out manually, making the processing quality vary. In contrast, laser cutting can help reduce assembly workload, assembly time, material and labor costs.

Steel sheets cut out by laser has high-quality cutting slits, desirable cutting surface verticality. And the cutting surface is smooth and free of slag and thick oxide layer. The finished material needs no following process and can directly go to welding.