Bodor 10kW+ high power laser cutting optimized and accelerated

Recently, Bodor launched the newly high-quality BodorGenius 12000W laser head and the world’s only tailor-made 22000W laser, transforming ultra-high power laser cutting into a reliable and efficient process at a higher level.

The former optimizes Bodor’s stable and efficient laser cutting solutions, and the latter accelerates its progress on advanced 10kW+ laser cutting technologies.

After getting popular among laser cutting solution providers in the world market, 10kW+ laser, whose power beyond 10,000 watts, is now spreading fast worldwide to bring about upgrades and transformation to the metal cutting process.

However, we should not let ourselves lay complacent about the present circumstances and feel no need to make progress. Despite the rapid development of 10kW+ laser applications, the efficiency and stability of functional components has been an obstacle for clients to making use of 10kW+ laser cutting equipment.

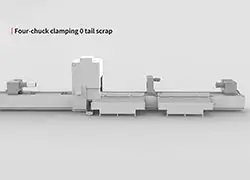

As a global leader in the market of 10kW+ laser cutting equipment, Bodor launched the world’s first 40,000 watts laser cutting machine and the 500+ units of 10kW+ laser cutting machines sold show that Bodor is making excellent progress on providing its clients better laser cutting solutions. Bodor understands that efficiency and stability are important to clients who purchase high-power laser cutting machines. Therefore, it launched the new BodorGenius 12kW laser head and the world’s only tailor-made 22kW laser.

The self-developed BodorGenius 12000w laser head achieves Protection level IP65 thanks to the dual protection of optical path: one on-chip protective lens and two under-chip protective lenses, lasting to protect the internal cavity from external pollution. The optical path and air path are optimized to reduce the interference of stray light and airflow fluctuation, which avoids unnecessary interference and ensures a good cutting effect and stable cutting quality.

The world’s only tailor-made 22kW laser researched and developed under the strategic cooperation between Bodor and Maxphotonics owns the features of the continuous and stable output of 22kW power laser, flat-top beam distribution, and anti-high-reflection protection technology, which helps Bodor increase 20% of the overall laser cutting efficiency and present high-class cutting effects, even for highly reflective materials.

But should we be content with these? As stated above, the ultra-high power laser cutting still has its difficulty, therefor Bodor will not throw itself to the present success but continue to strive to create the optimal laser cutting solution.