The FABRICATOR’s Leadership Summit report: Metal fabricators plan for growth

THE FABRICATOR MAY 2018

MAY 6, 2018

BY: TIM HESTON

Metal fabrication is already a complex animal, and it becomes even more so as shops navigate various external forces, from tariffs to customer consolidations. In March, shop executives gathered at the FMA Annual Meeting to talk about ways to turn these challenges into opportunities for growth.

The FABRICATOR’s Group Publisher Dave Brambert moderates a panel of four custom fabricator executives: Edwin Stanley of GH Metal Solutions, John Axelberg of General Stamping & Metalworks, Don Kammerzell of K-zell Metals, and Lori Tapani of Wyoming Machine Inc.

The current year is turning out to be a dynamic one for metal fabricators. Some are busting at the seams, trying to hire, train, and bring in equipment to meet rising demands for capacity. When customers grow, so do the custom fabricators serving them.

Throughout 2017 fabricators benefited from a business-friendly presidential administration. Regulations were cut, the corporate tax rate fell, the R&D tax credit was made permanent, and portions of the tax code were rewritten to encourage investment. Then came the new year and a host of challenges, from rising material prices and steel and aluminum tariffs to politicians’ saber rattling about trade wars.

The discussion was extraordinarily timely. Packard even kept his phone’s news feed on the podium, lest news about tariffs and trade should change during his talk. And news has of course changed since the panel discussion took place at the FMA meeting.

But whether one was for or against tariffs, all could agree with one comment McNeeley made during his keynote: “Everybody is interested in our industry now, and issue No. 1 is education. The real shortage is in leadership. Where’s the next generation of leaders going to come from?”

Those leaders will need to know how to deal with the challenges fabricators face, from trade and tariffs and finding good employees to investing in the right machines and technology. Amid a whirlwind of news, the FMA event ultimately was about how, in the face of tailwinds and headwinds, a metal fabricator can grow.

Producing More

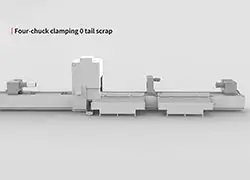

Representatives from five major machine tool providers—Amada America Inc., BLM Group, Bystronic, MC Machinery Systems, and TRUMPF—talked about how technology can help each person produce more, faster.

Their focus was not on how many inches per minute this or that laser cuts, but on how quickly quality products can flow through a plant. To produce more, part velocity is key, and machines connected with software can be one tool to make it happen.

“We firmly believe in the old saying, you’re either growing or shrinking. You can’t stand still for very long.”

Don McNeeley, president and CEO of Chicago Tube & Iron, speaks about the industry’s challenges during the keynote panel discussion, with fellow panelists Ladd Hall, executive vice president of flat rolled products for Nucor Corp., and (standing) John Packard, founder and publisher of “Steel Market Update.”

Don McNeeley, president and CEO of Chicago Tube & Iron, speaks about the industry’s challenges during the keynote panel discussion, with fellow panelists Ladd Hall, executive vice president of flat rolled products for Nucor Corp., and (standing) John Packard, founder and publisher of “Steel Market Update.”

That was panelist Edwin Stanley, vice president of operations at GH Metal Solutions, Fort Payne, Ala. The panel consisted of executives from two large fabricators with several hundred employees—GH Metal Solutions and South Bend, Ind.-based General Stamping & Metalworks—along with two smaller fabricators with fewer than 50 employees—K-zell Metals in Phoenix and Wyoming Machine in Stacy, Minn. All four essentially discussed ways their companies would grow in the modern manufacturing world, where each resource must provide more value than ever.

The next FMA Annual Meeting will take place March 5-7, 2019, in Nashville, Tenn.