Key Edges of Fiber Laser Cutting Machines

Fiber laser cutting machines are the latest type of laser cutting equipment, and has gradually take the place of other similar cutting equipment such as CO2 laser cutting machines and become the mainstream. This is due to some key edges of fiber laser.

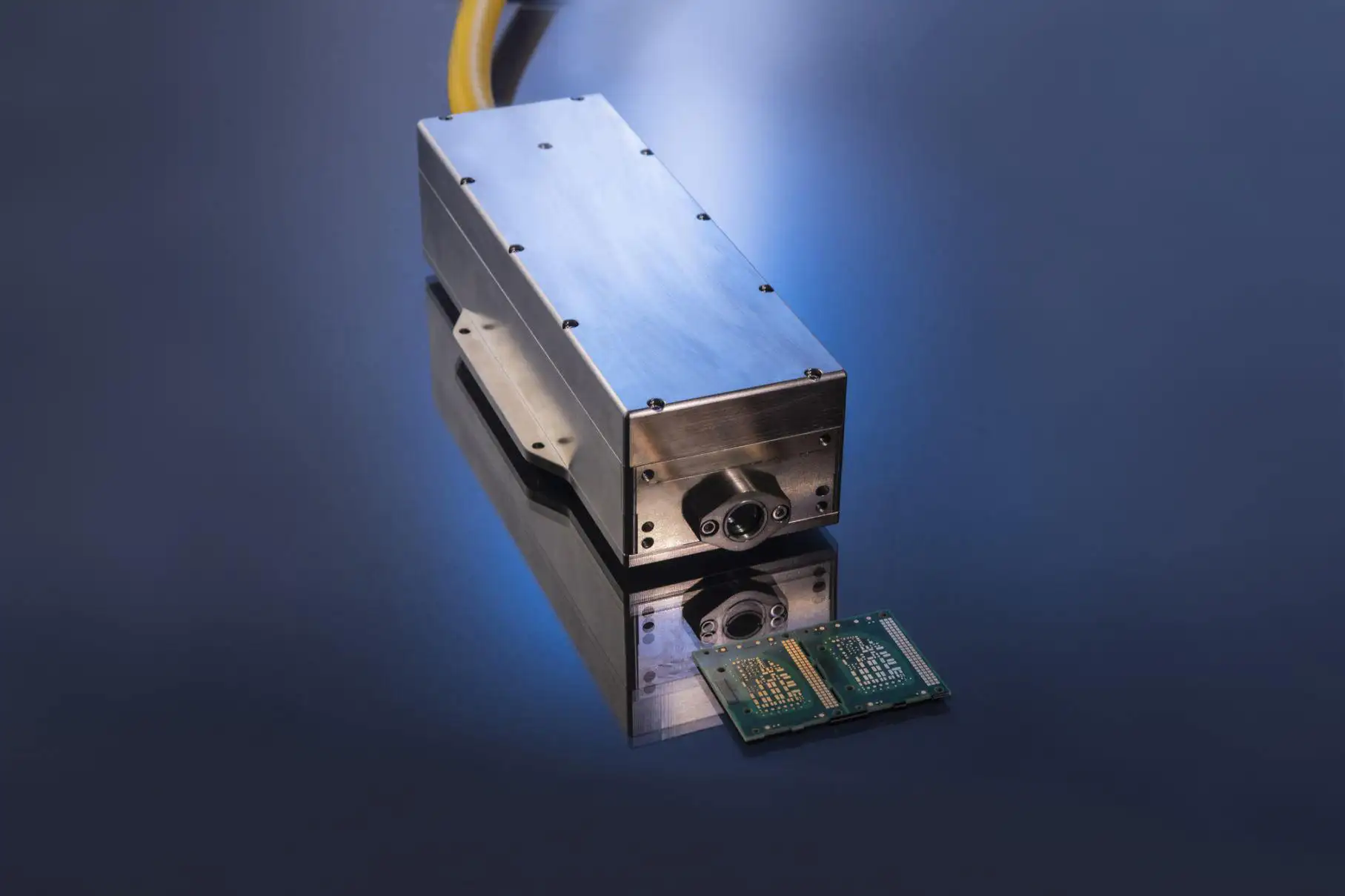

Low Costs of Use and Maintenance

① The photoelectric conversion efficiency of fiber laser can reach 30%, which is 3 times as high as CO2 fiber laser and 10 times as YAG. Total power consumption of a fiber laser machine only makes 20%-30% of that of CO2 laser.

② Fiber laser are powered only by electricity and does not need auxiliary gas, saving a considerable amount of costs.

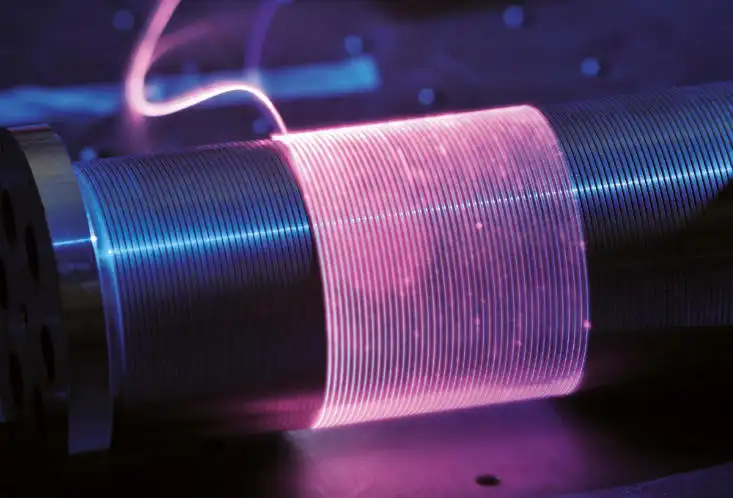

③ Fiber transmission requires no reflective lens, saving maintenance such as parts replacement.

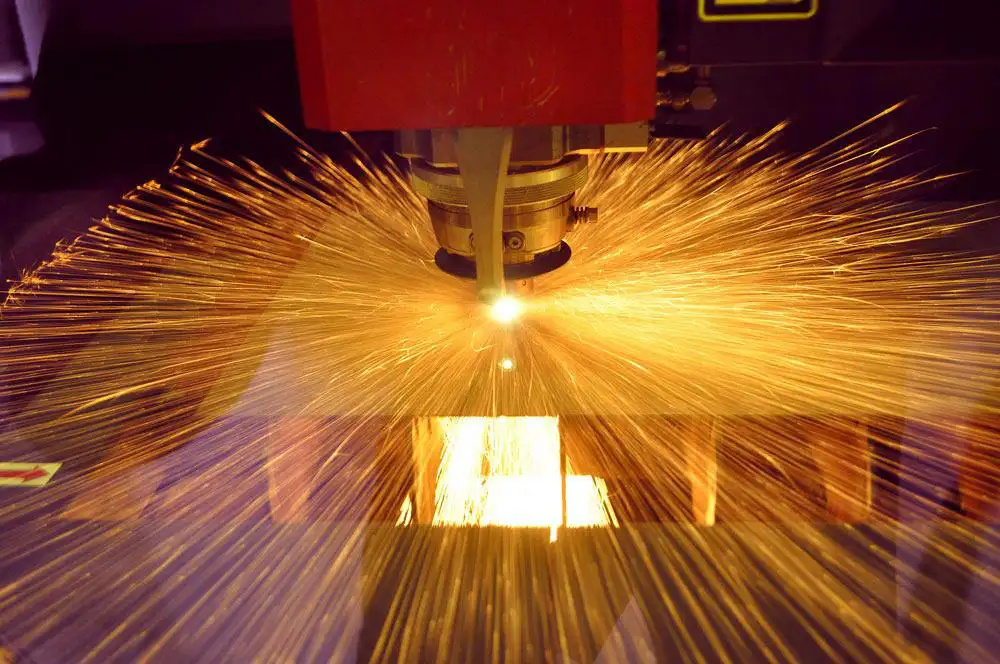

Great Processing Speed

① The max cutting speed of fiber laser cutting machines can reach 10m/min, and the max positioning speed can reach 30m/min, which are twice as fast as CO2 fiber laser cutting machines ( in the same power) and 4-5 times as YAG. That makes fiber laser highly suitable for mass production.

② Once the product blueprint is finished, fiber laser processing can be initiated right away, and you can produce the products in the shortest time.

③ Due to the semiconductor modular and redundant design, there is no optical lens in the resonant cavity, so fiber laser machines can start working without any preparation time.

Favorable Cutting Quality

① The focus spot of fiber laser is much smaller, so the cutting line is thinner and more exquisite.

② Fiber laser head does not contact material, avoiding scratches on the surface.

③ The thinner cutting line makes hot area smaller, which lowers the deformation to the least.