Step Into the Future with

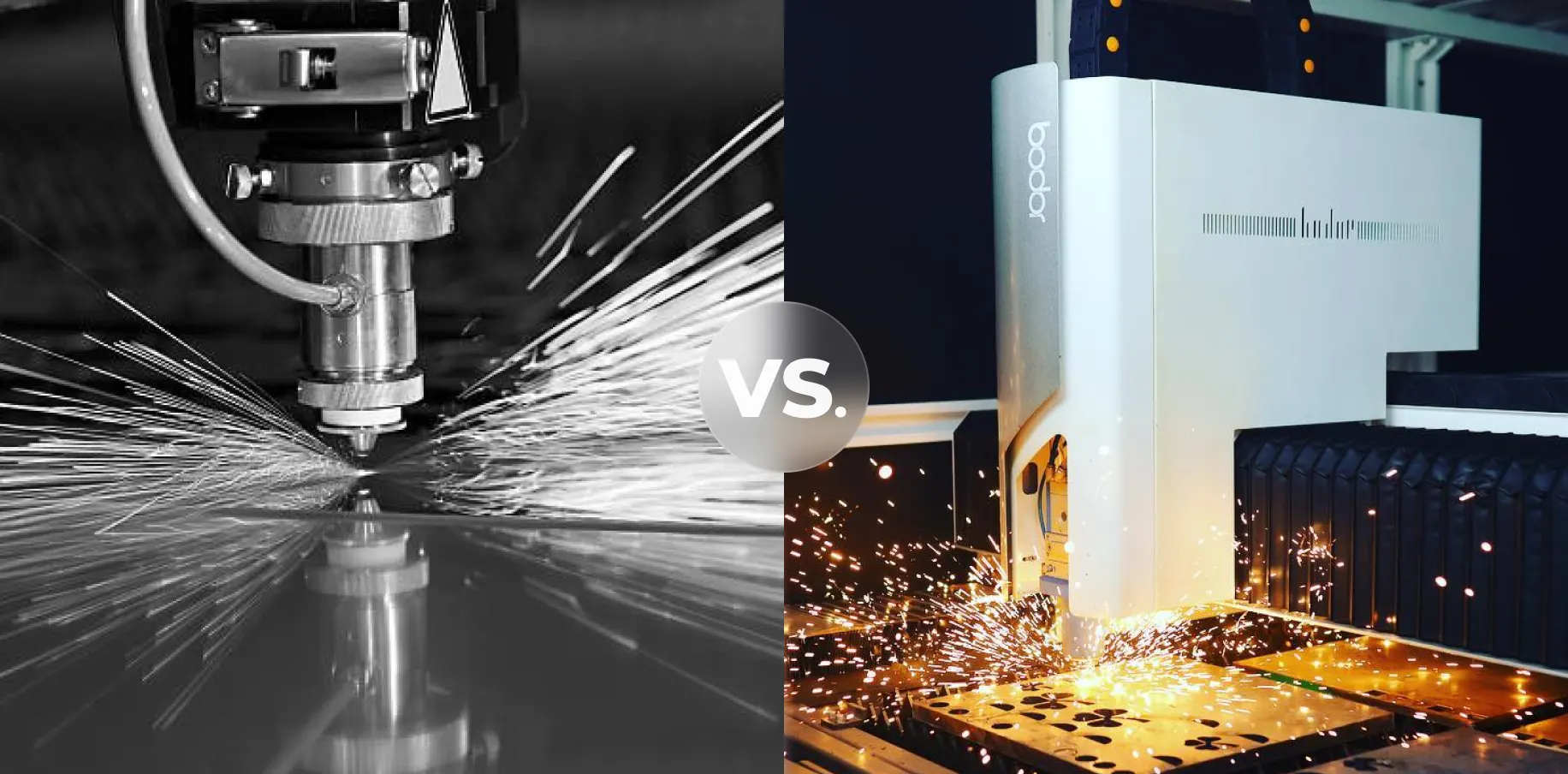

10kW+ Fiber Laser

The Cost-effective Substitute to CO2 Cutting

Request samples

Get a quote

ROI esitimation

Are you encountering these problems with your CO2 cutter?

Limited cutting speed

The cutting speed of CO2 lasers cannot exceed 10m/min because of its power limitation, falling short of the growing demand for high-volume and faster production.

Huge gas consumption

The gas cost of CO2 laser cutter is quite expensive. It needs CO2, nitrogen and helium for the laser beam, and oxygen and nitrogen for the cutting process.

Narrow cutting thickness range

The CO2 cutters are only capable of processing up to 25mm of carbon steel and stainless steel at a rather slow speed. This drawback spells trouble in increasing productivity and catering to a diverse range of business needs.

High electricity consumption

The CO2 laser cutters waste a lot of electricity and power as they turn 90% of electricity into heat and vapor, and only 10% into laser.

Troublesome maintenance procedure

The maintenance procedure is time-consuming and laborious. Constant adjustment, cleaning, and replacement of reflective mirrors and corrugated tubes serve as a detriment to reducing labor costs.

10kW+ laser cutting,

a state-of-the-art technique to tackle all your obstacles.

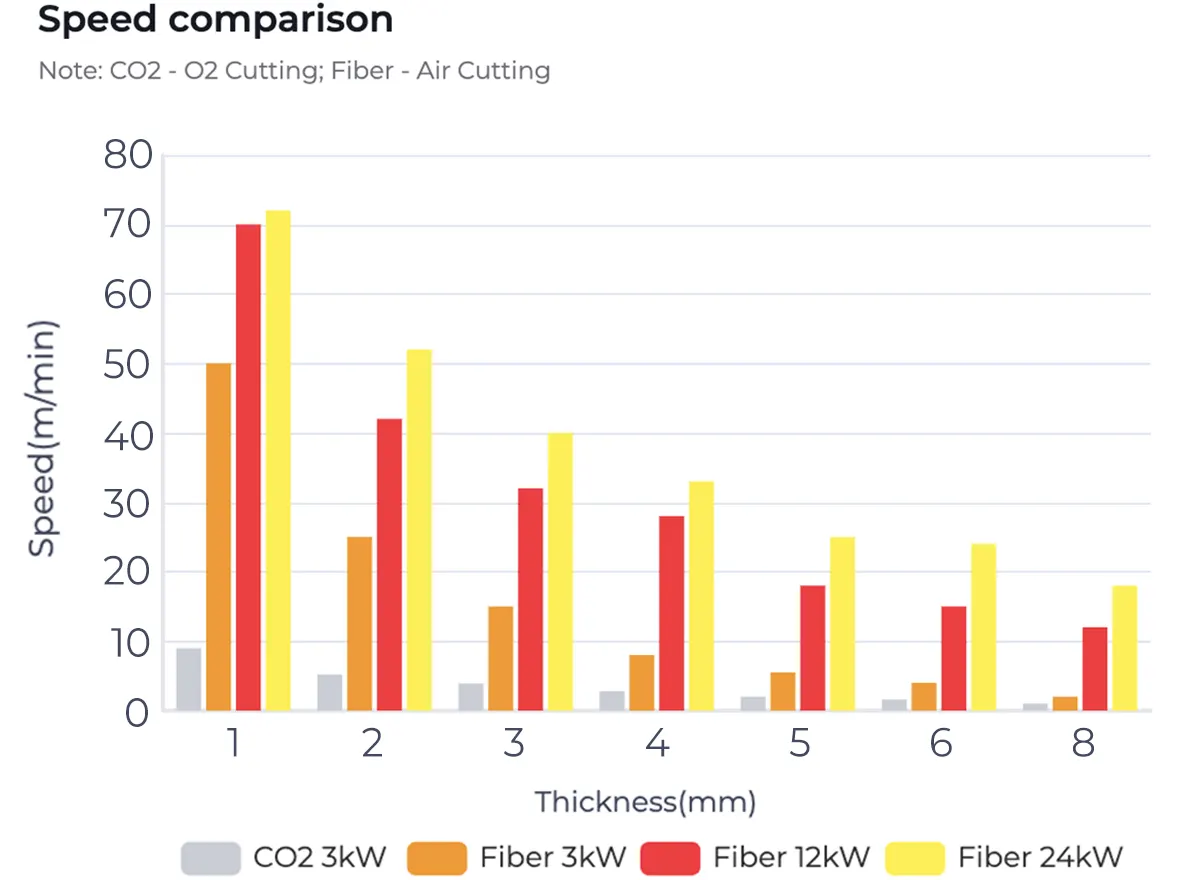

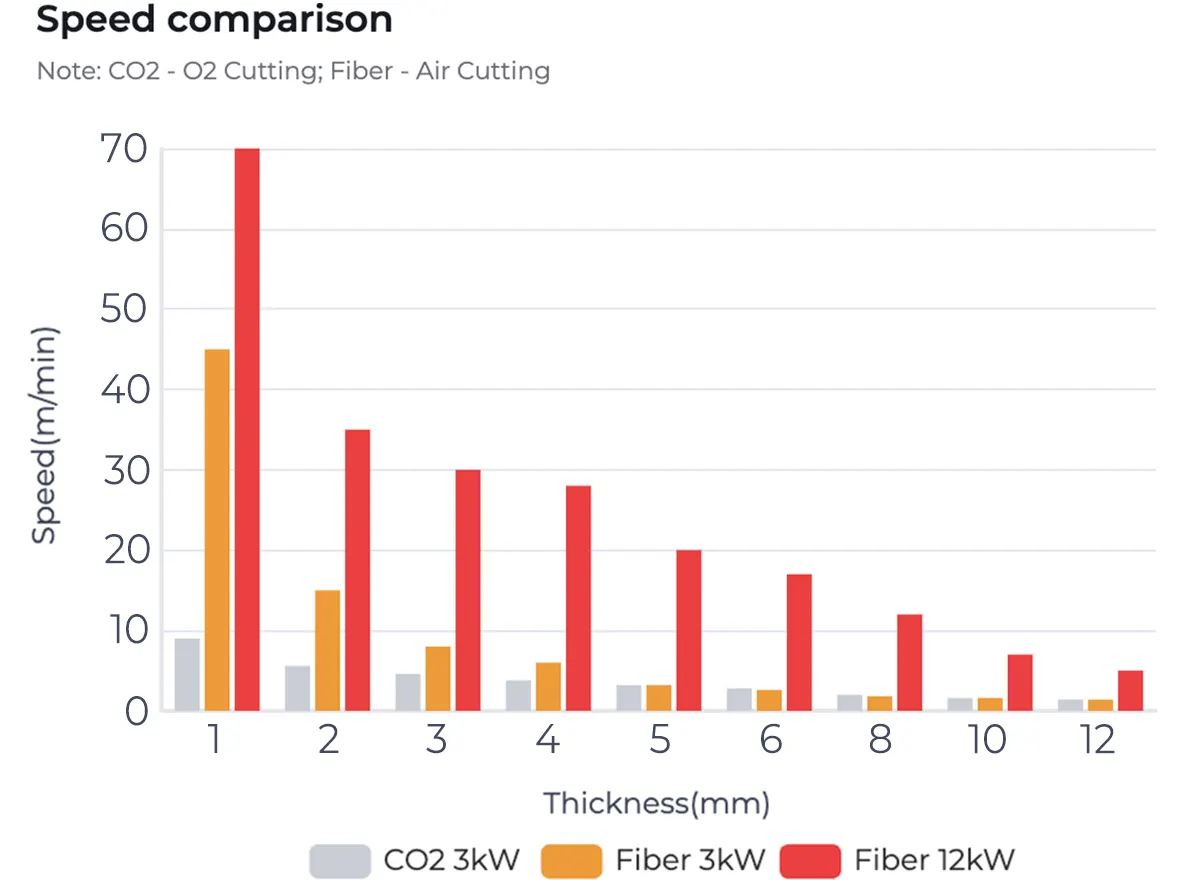

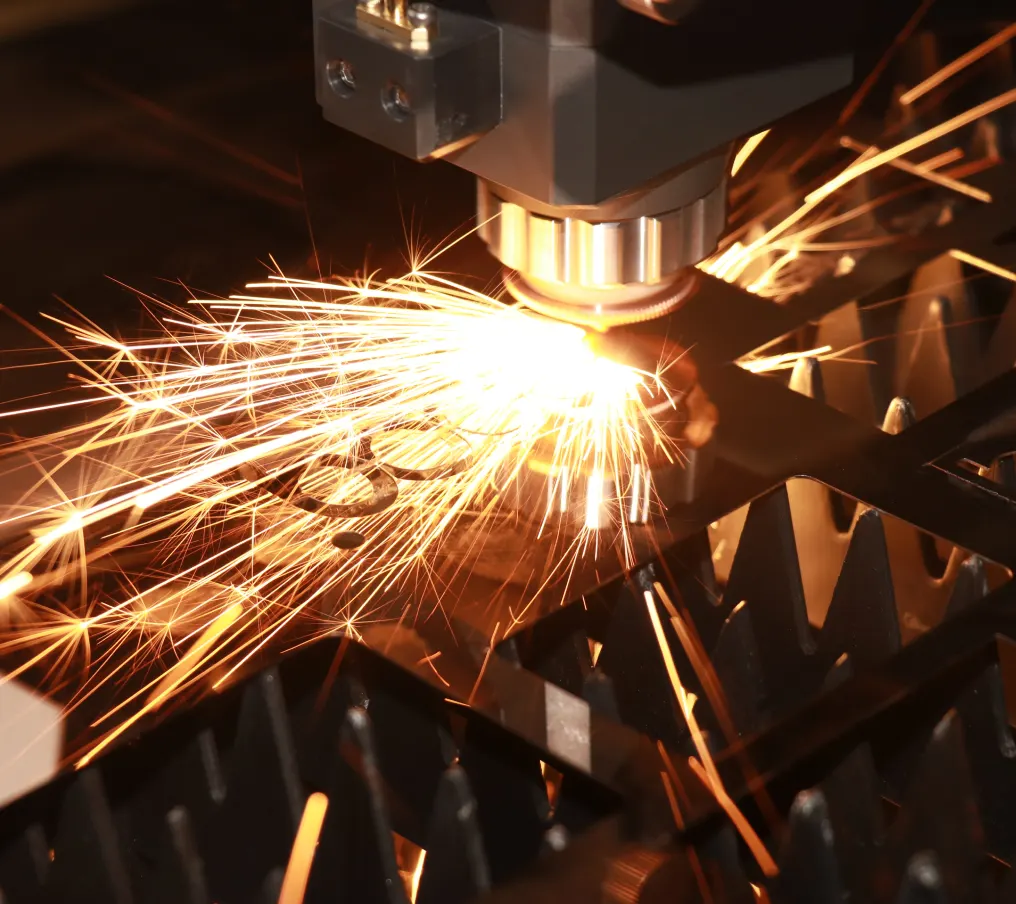

Boosts cutting speed remarkably

10kW+ fiber lasers can cut up to 8 times faster than CO2 lasers. This remarkable speed improvement will increase productivity as more material can be processed in less time, resulting in higher revenue for companies.

Stainless steel

Carbon steel

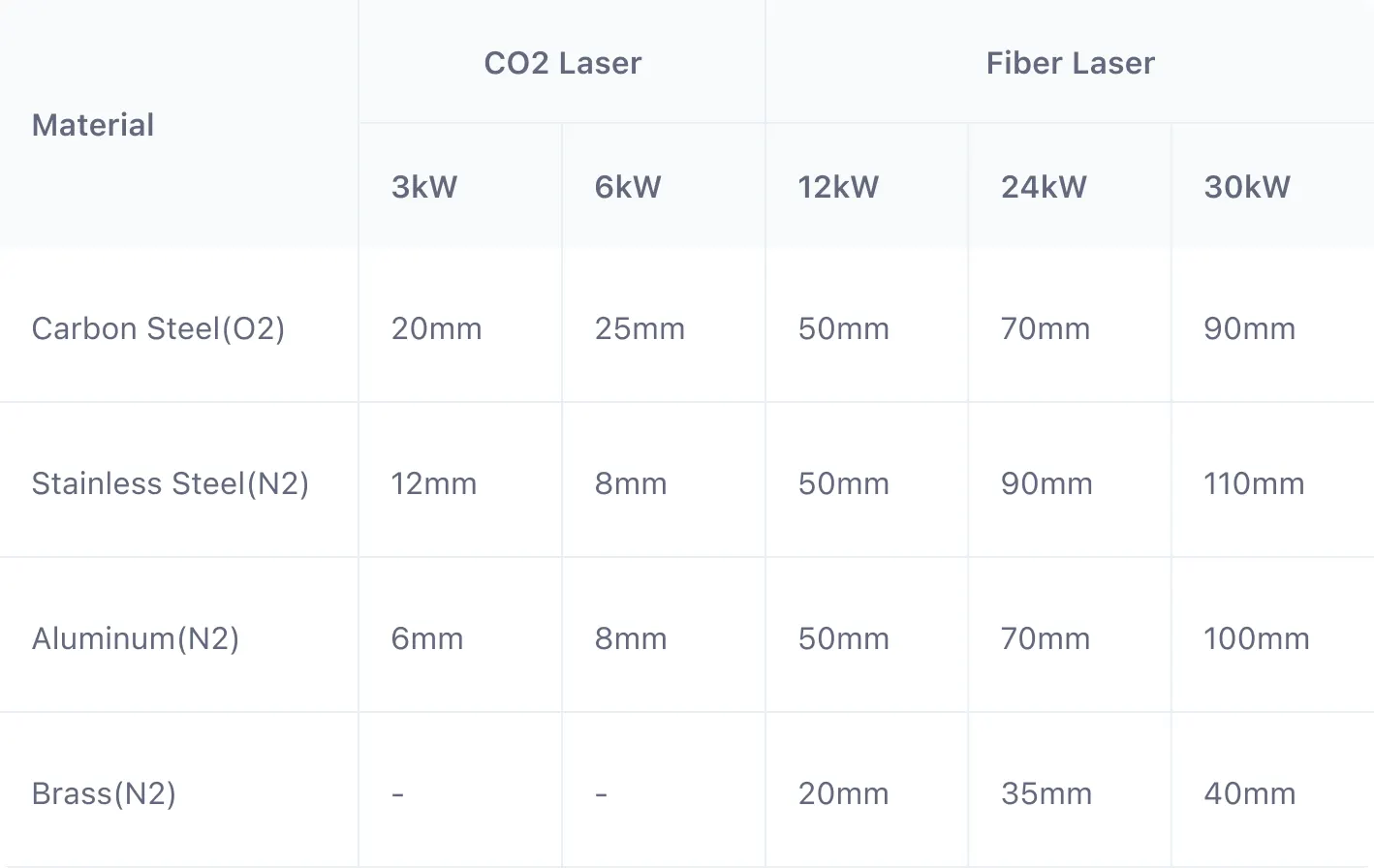

Expands cutting thickness significantly

10kW+ fiber lasers can handle metal plates up to 110mm thick. This ability to cut thick metal plates allows companies to work with a wider range of products, and to complete their tasks faster and more efficiently.

Improves electricity efficiency drastically

10kW+ fiber lasers reach 40%+ of the photoelectric conversion rate, which means almost half of the electrical energy will be converted into laser energy. Less wasted energy and reduced power cost are easily achievable.

Delivers cutting-edge air cutting technology at an affordable price

10kW+ fiber lasers with air cutting method produces precise and flawless cuts, and omits gas consumption such as oxygen and nitrogen, being consequential in reducing gas cost, boosting productivity, and decreasing environmental footprint.

Makes maintenance easy and time-saving

Employing 10kW+ fiber laser cutters cuts out the continual adjustment, cleaning, and replacement of reflective mirrors and corrugated tubes. Not only does it eliminate manual intervention and downtime but also increases production capacity and revenue.

10kW+ laser vs. CO2 guidebook

In this guidebook, you will be able to get a detailed introduction and comparison between 10kW+ fiber lasers and CO2 lasers, including:

- Market overview

- Laser beam comparison

- Cutting speed comparison

- Cutting material & thickness comparison

- Operational costs comparative analysis

Applicable industries

Electronics

Metal fabrication

Agricultural machinery

Automotive manufacturing

Metal furniture manufacturing

Kitchenware manufacturing

Client’s success story

Achieving Cost Reduction and Sustainable Production in Global Agricultural Equipment Industry

22%

Reduction in costs

8x

Increase in speed

90%

Increase in cost-benefit

I wanted to take a moment to express my gratitude for the outstanding service support that Bodor provided during the installation. The installation was completed without any issues, and all the machines are running perfectly. Their expertise and professionalism made a significant difference, and we will not hesitate to recommend Bodor’s service to anyone in need.

Shreenivas Nazare

Production Manager of MASCHIO GASPARDO

Request samples

Get a quote

ROI esitimation

Get a Quote

At Bodor Laser, we evaluate your cutting requirements and offer free consultation service on a case-by-case basis. If you require further suggestions, please fill out the form to contact our sales experts.