Step Into the Future

with 10kW+ Laser Cutting

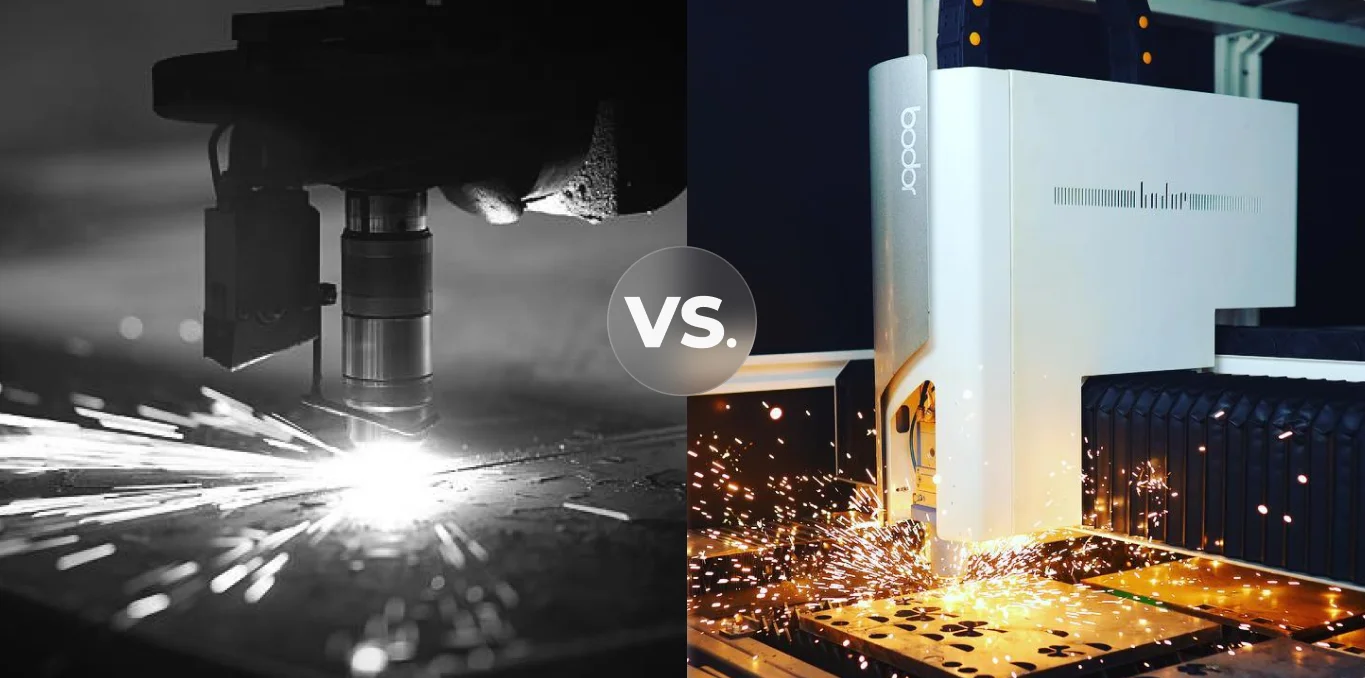

The superior alternative to plasma cutting

Request samples

Get a quote

ROI esitimation

Are you facing these challenges with your plasma cutter?

Bad quality and appearance of cutting surface and edge

Plasma cutting produces a notable heat-affected zone, leading to potential metal distortion. It also results in slag, dross, and rough edges that typically require extra grinding for smooth assembly. Additionally, products often exhibit a pronounced taper, requiring further refinement

Unhealthy working environment

The working environment is unhealthy and noisy because of the high concentrations of harmful dust and loud noise every day.

Slow cutting speed

The process of plasma cutting is inherently time-consuming. The generation and maintenance of the plasma arc, along with the careful control required to process, all contribute to a slower overall cutting speed.

High operational costs

The frequent replacement of consumables, manual work, and high energy consuming lead to high operational costs.

Cumbersome processing

The cutting process, burdened with multiple steps like scribe drilling and corrective shaping, is both time-consuming and inefficient. With the machine platform's limitations, frequent workpiece transferring is necessary.

10kW+ laser cutting, a powerful way to solve all your problems!

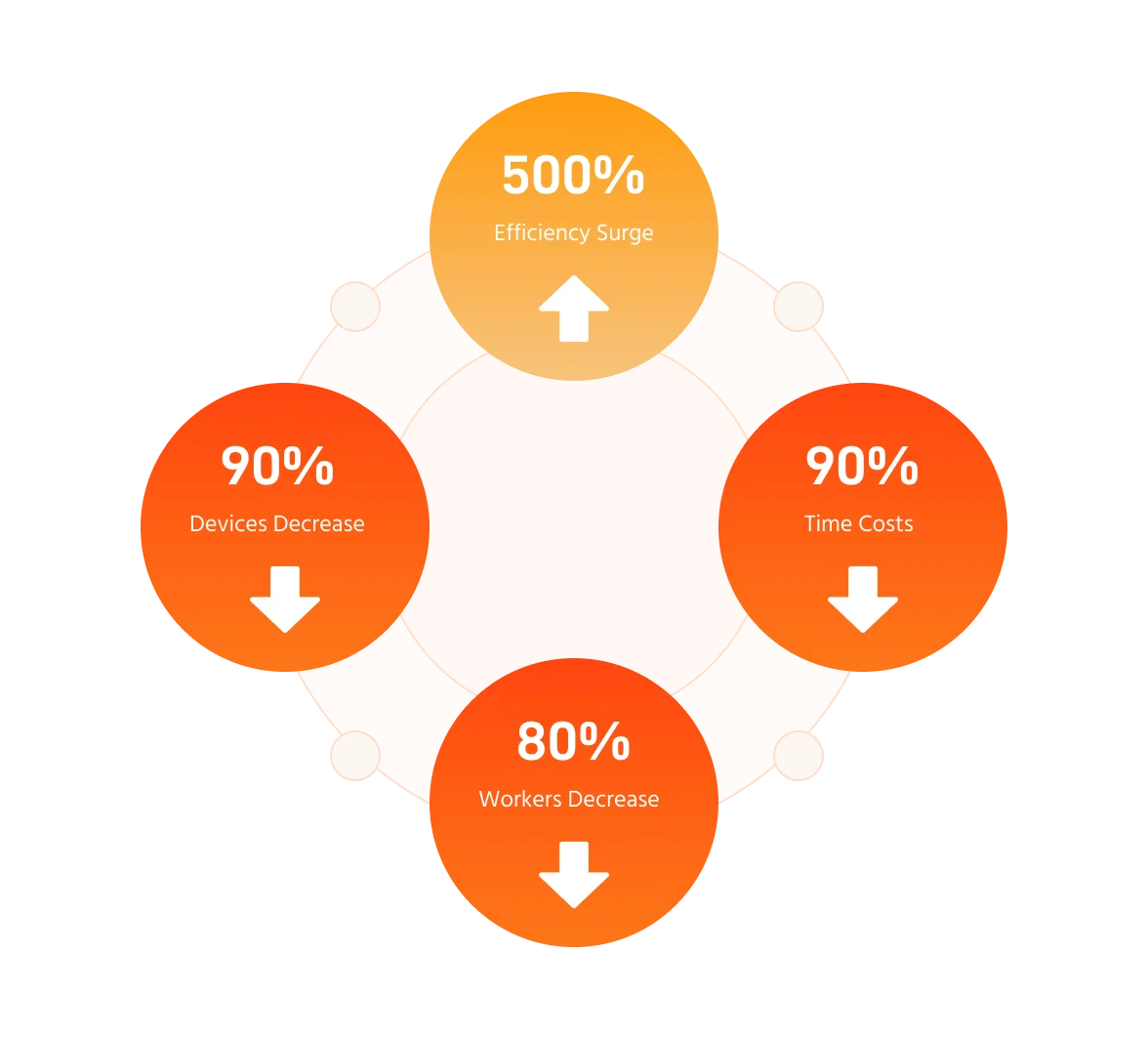

Omit redundant processes & workpiece transfer

When using a plasma cutter, additional resources such as three shearing machines (requiring six operators) and two drilling machines (require four operators) are necessary to complete the task.

However, a switch to laser cutting technology changes this situation dramatically. A single laser cutting machine, operated by only two people, can do the same work. This switch drastically reduces labor costs and improves operational efficiency.

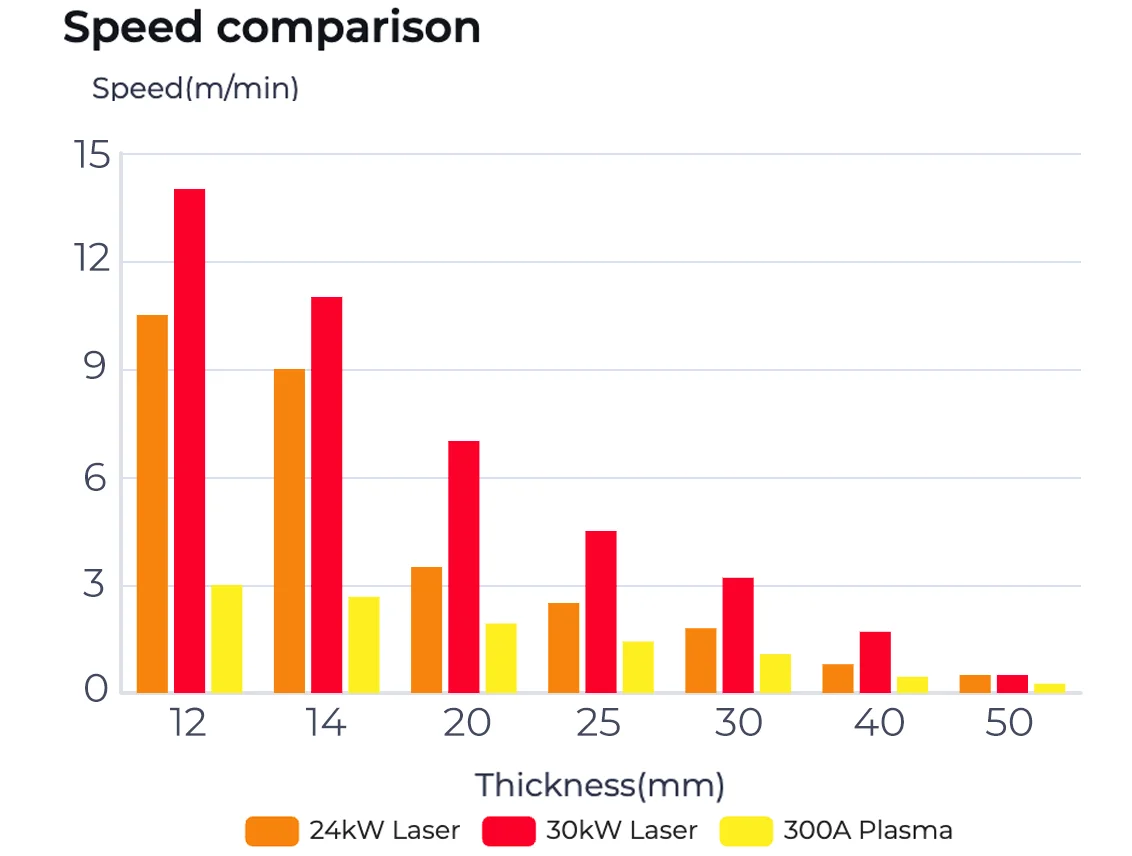

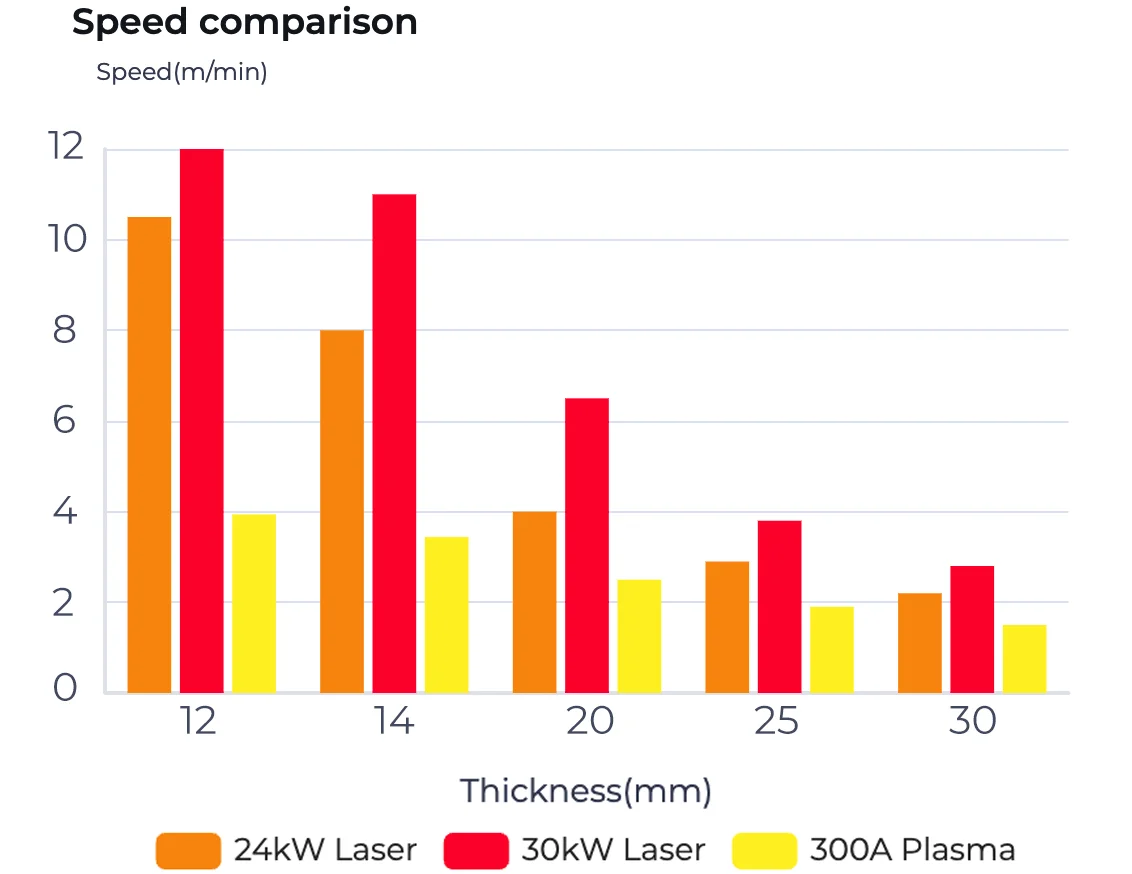

Increase speed, productivity and efficiency

For manufacturers, cutting speed is one of the crucial factors that must be seriously considered. Compared to plasma cutting, 10kW+ high-power laser cutting offers significant advantages in terms of speed, achieving cutting speed up to 3 times faster. This increase in speed translates to higher productivity and earnings, potentially allowing the company to recoup the cost of the laser cutting machine within 3 months at the earliest.

Stainless steel

Carbon steel

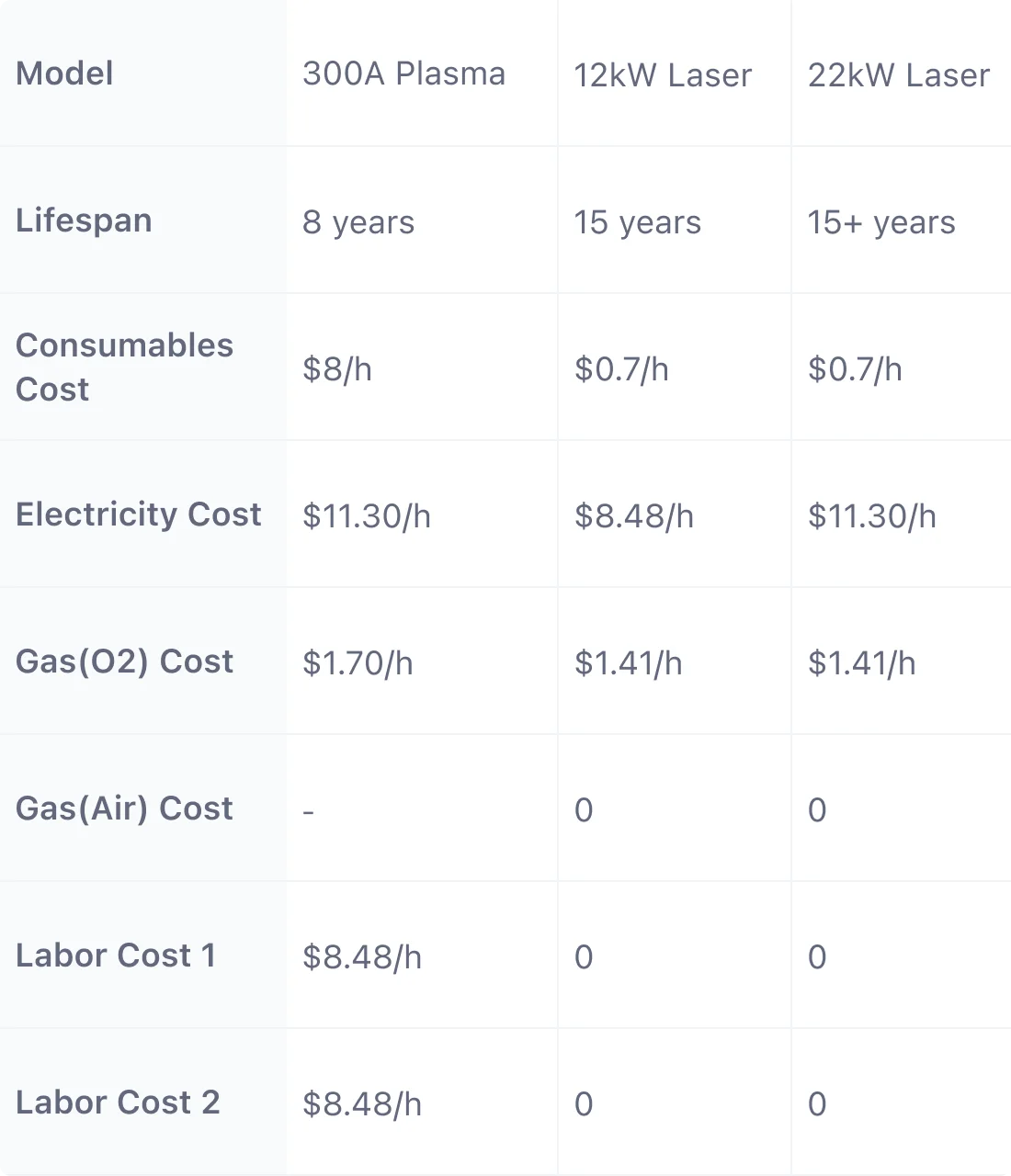

Lower operational costs substantially

The operational costs of a 10kW+ laser cutter are much lower than that of a plasma cutter.

To roughly estimate, an 8-year operational costs for a plasma cutter are DOUBLE that of a 24kW laser cutter’s operational costs over a 15-year lifespan.

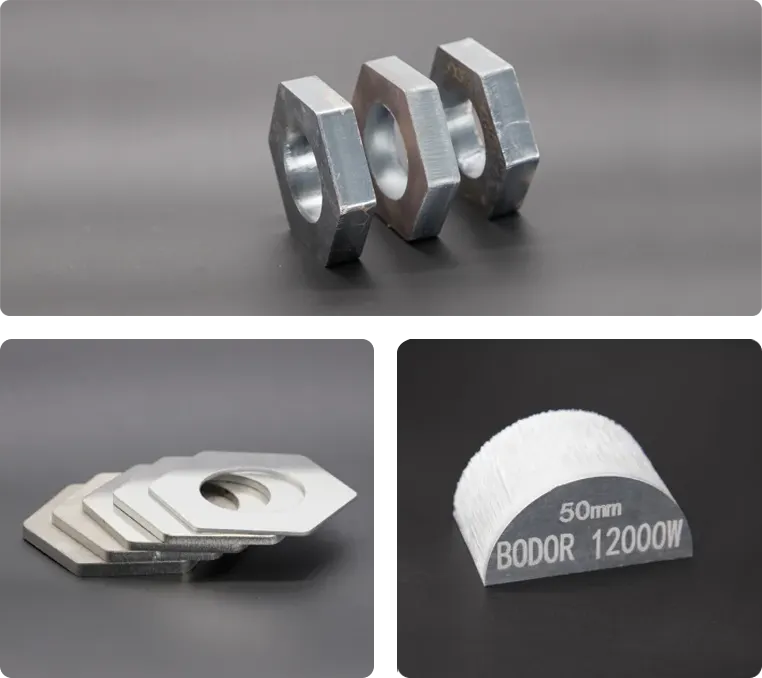

Provide smooth and high-quality workpiece

With the heat-affected zone in laser cutting limited to a mere 0.1-0.4mm, materials experience minimal deformation. The surface and edge of metal parts processed by laser cutting are usually smooth, burr-free, and scratch-free, reducing friction, wear and corrosion. Moreover, 10kW+ lasers can shape the bevel in one go, combine multiple stages like cutting and milling, offering high surface quality.

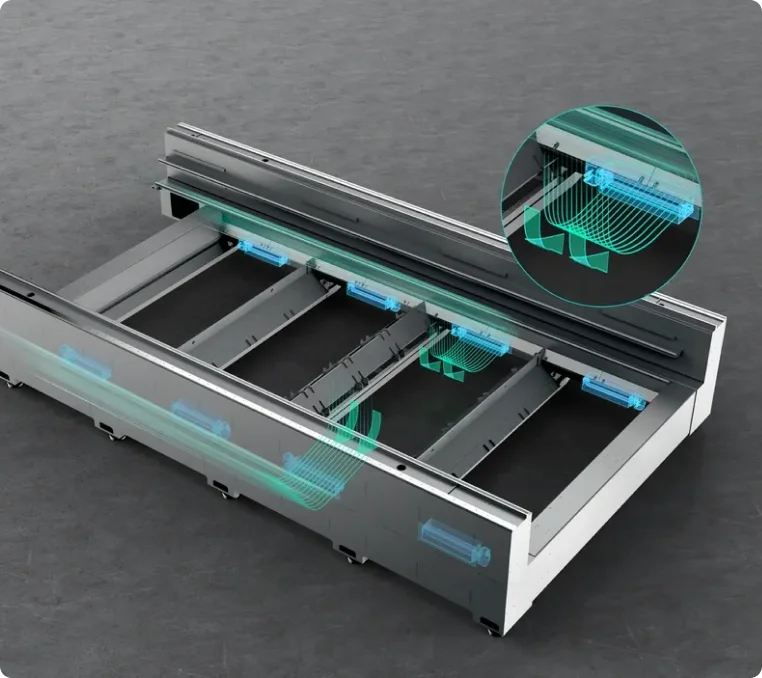

Present sustainability and future industry trend

10kW+ lasers negate the need for consumables, such as electrode and vortex ring required in plasma lasers, minimizing waste and environmental impact. With the protective cover and the smoke and dust extraction function, Bodor 10kW+ high-power lasers also provide a safer work environment by not producing harmful radiation or necessitating harmful chemicals. Moreover, compared to other manufacturing equipment, fiber lasers generate less noise, reducing noise pollution. Consequently, Ultra-high-power lasers offer a unique convergence of environmental friendliness and enhanced operational efficiency, underscoring their potential in sustainable industrial practices.

Applicable industries

Specialized vehicles

Hardware tools

Pressure vessel

Engineering machinery

Steel structure bridge

construction

Shipping containers

Request samples

Get a quote

ROI esitimation

Get a Quote

At Bodor Laser, we evaluate your cutting requirements and offer free consultation service on a case-by-case basis. If you require further suggestions, please fill out the form to contact our sales experts.