A Polish Manufacturer Discarding the Slow and Inefficient Plasma Cutter

Three Bodor Laser Equipment Help Alpinall Laser Thrive in the Metal Fabrication Business

Alpinall Laser's Success Story

100%

Cutting efficiency raised

50%

Processing speed increased

6x

Production cost reduced

Located in Województwo dolnośląskie, Poland, Alpinall Laser, a new and promising branch of Alpinall and an enterprise with expertise in metal processing, is dedicated to providing various services for metal fabrication. The company processes metals such as 0.8-40mm carbon steel and stainless steel, 0.8-30mm aluminum, and 0.8-18mm brass. Since the company was established, it has completed over 500 manufacturing projects, reaching a remarkable 100% customer satisfaction rate.

INDUSTRY

Metal Fabrication

INSTALLATION TIME

Jan. 2022

LOCATION

Województwo dolnośląskie, Poland

A slow and costly plasma cutter hindered production efficiency

When Alpinall Laser started running, it had a 100A plasma cutting machine to process metal sheets and tubes. Not long after, the plasma cutter exposed many problems that affected productivity dramatically.

The cutting speed was too slow to finish the daily scheduled production volume. Not only did it take a long time to pierce through the metal, but also it cut at a deficient speed. For example, a 100A plasma cutter could only process 30mm carbon and stainless steel sheets at a 0.2m/min speed. Moreover, the company had to turn off the machine approximately every two hours to change nozzles, decreasing active working time. As a result, the production efficiency was lamed by the plasma cutter.

Frequent consumables replacement and heavy auxiliary gas usage increased the running costs of Alpinall Laser. Plasma cutting machines required many consumables, including nozzles, electrodes, shields, retaining caps, and swirl rings, as they wore quickly. Running plasma cutters needed auxiliary gases such as oxygen and nitrogen to generate plasma arc and prevent oxidation and contamination.

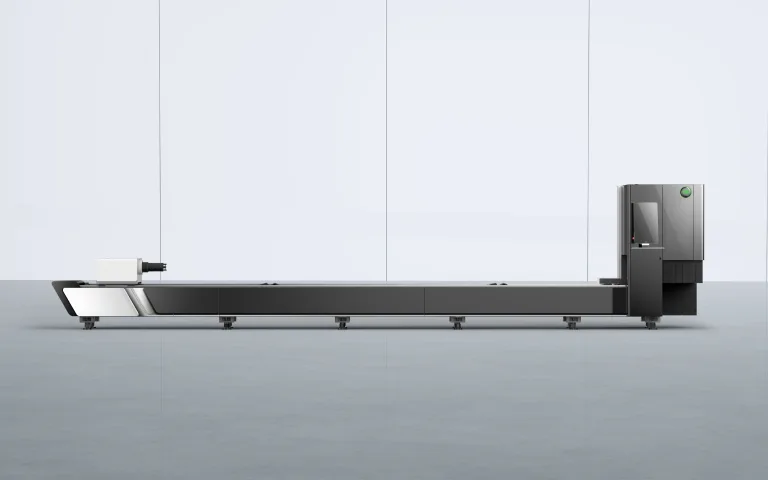

Cut various metals fast with two Bodor C3 and one K1 laser cutters

The Polish metal fabricator wanted a preferable manufacturing solution to improve production efficiency and reduce costs. It researched several methods and discovered that laser cutting technology was the most advanced approach to fulfilling its demand.

Alpinall Laser paid attention to the Bodor brand in the STOM-TOOL fair, a major European-wide industry event for tools and CNC metal fabrication machines. The Polish sales manager of Bodor Laser introduced the laser cutting machines to Alpinall Laser in detail and provided a cutting demo on-site. The rapid cutting speed of Bodor C3, a base sheet fiber laser metal cutting machine with complete protection, impressed Alpinall Laser. It immediately knew that this was the powerful tool it needed.

In 2022, Alpinall Laser invested in three Bodor laser cutting machines, a C3 12kW and a C3 3kW sheet laser cutters, and a K1 tube laser cutter in a row to amplify its service categories and productivity. Three machines were packaged and delivered to Województwo dolnośląskie shortly after.

Reap 100% cutting efficiency enhancement and 6X production cost reduction

After adopting the Bodor C3 and K1 laser cutting machines, Alpinall Laser significantly boosts its cutting speed by 50% and cutting efficiency by 100%. Now, it can process metal sheets and tubes together and does not need to shut down the machine to change consumables. The increased production volume brings more businesses and revenues to Alpinall Laser.

The operational cost decreased drastically as laser cutting machines are not required to replace many consumables. In addition, Alpinall Laser applies the air cutting technique to cut metals, saving the costs for auxiliary gases. With a larger production volume but lower production cost, the best metal manufacturer in Województwo dolnośląskie acquires much more profits.