Transforming productivity with state-of-the-art laser cutting solutions

Embrace Innovation and Invest in Long-term Success

↓

Akışlar Metal Industry's Success Story

50%

Increase in profit

2×

Thickness capacity

Expanded order types

Akışlar Metal Industry , a metal works and iron products leader with 40 years of experience, elevated their production capabilities and enriched their offerings by embracing cutting-edge laser cutting technology.

INDUSTRY

Metal Fabrication

DELIVERY TIME

June 2020

LOCATION

İzmir, Turkey

For nearly 40 years, Akışlar Metal Industry has built a solid reputation in the metal works and iron products industry. With a steadfast commitment to excellence and innovation, the company closely monitors technological developments and continually adapts its processes to meet the ever-changing demands of its customers. As a result, Akışlar Metal Industry now boasts an impressive portfolio of diverse product offerings, bolstered by its efficient and skilled workforce.

Outdated Technology Hinders Productivity

Akışlar Metal's primary goal is to help its customers address their metal processing challenges with speed and efficiency. Initially, the company relied on two CO2 laser cutting machines to fulfill the metal sheet processing needs of their clientele. However, after nearly eight years, these older machines began to limit Akışlar Metal's productivity, consumed excessive electricity, and yielded suboptimal processing results.

Embracing Advanced Laser Cutting Technology

Recognizing the need for a more advanced and efficient metal cutting solution, the company explored the benefits of ultra-high power fiber lasers. After careful consideration and comparing available options, Hasan AKIŞ, the owner of Akışlar Metal, decided to invest in a Bodor S-Series 15kW fiber laser metal sheet cutting machine in June 2020.

The Impact of Cutting-Edge Laser Cutting Technology on Akışlar Metal's Operations

More than a year after integrating the Bodor S-Series 15kW fiber laser cutting machine into their operations, Akışlar Metal has experienced a significant increase in efficiency and an expanded range of order types, leading to remarkable improvements across multiple areas:

Enhanced Profitability

Akışlar Metal reported a 50% increase in profit, demonstrating the transformative impact of advanced laser cutting technology on their bottom line.

Streamlined Production Process

The average production time was reduced by 50%, enabling the company to fulfill orders faster and improve overall customer satisfaction.

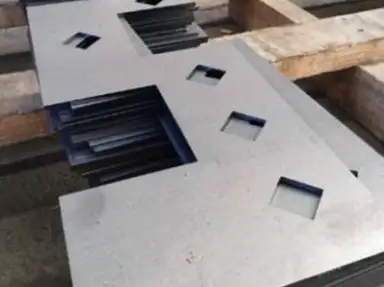

Expanded Cutting Capabilities

The new laser cutting machine increased the company's thickness capacity up to 40mm, allowing them to work with a broader range of materials and meet diverse customer requirements.

Versatile Order Processing

With the ability to process almost all types of orders in the market, Akışlar Metal has significantly expanded its customer base and solidified its position as an industry leader.

#WhyBodor: A Partnership Rooted in Innovation and Efficiency

When asked about his decision to choose Bodor, Hasan AKIŞ cited the impressive efficiency and excellent value for money offered by their laser cutting machines. Initially planning to purchase a 12kW IPG power laser, he was delighted to be offered a promotional price and an upgrade to the 15kW IPG power laser. The ability to work more efficiently, save costs, and accept a greater variety of orders made Bodor the obvious choice for Akışlar Metal Industry.