Discard the Plasma Cutting Machine and Upgrade to 22kW High-power Laser

A Swedish Grapple Manufacturer Reaps High Precision & Superior Cut Quality

HSP Gripen's Success Story

8x

Precision increased

98%

Products with taper decreased

100%

After-sales service satisfaction

Established in 1994, HSP Gripen, a Swedish cutting-edge hydraulic grapple manufacturer, is devoted to providing innovative and durable solutions for the forestry equipment and machinery industry. Today, Gripen owns multiple product lines including standard, heavy-duty, V-shape, etc. to meet various clamping needs and offer an excellent customer experience.

INDUSTRY

Grapple Manufacturing

INSTALLATION TIME

February 2023

LOCATION

Hudiksvall, Sweden

The Old Plasma Cutter- Low Precision and Distinct Tapers

Gripen produces exquisite grapples using 40mm Hardox® wear plates. It is a special kind of steel plate with high hardness and long durability.

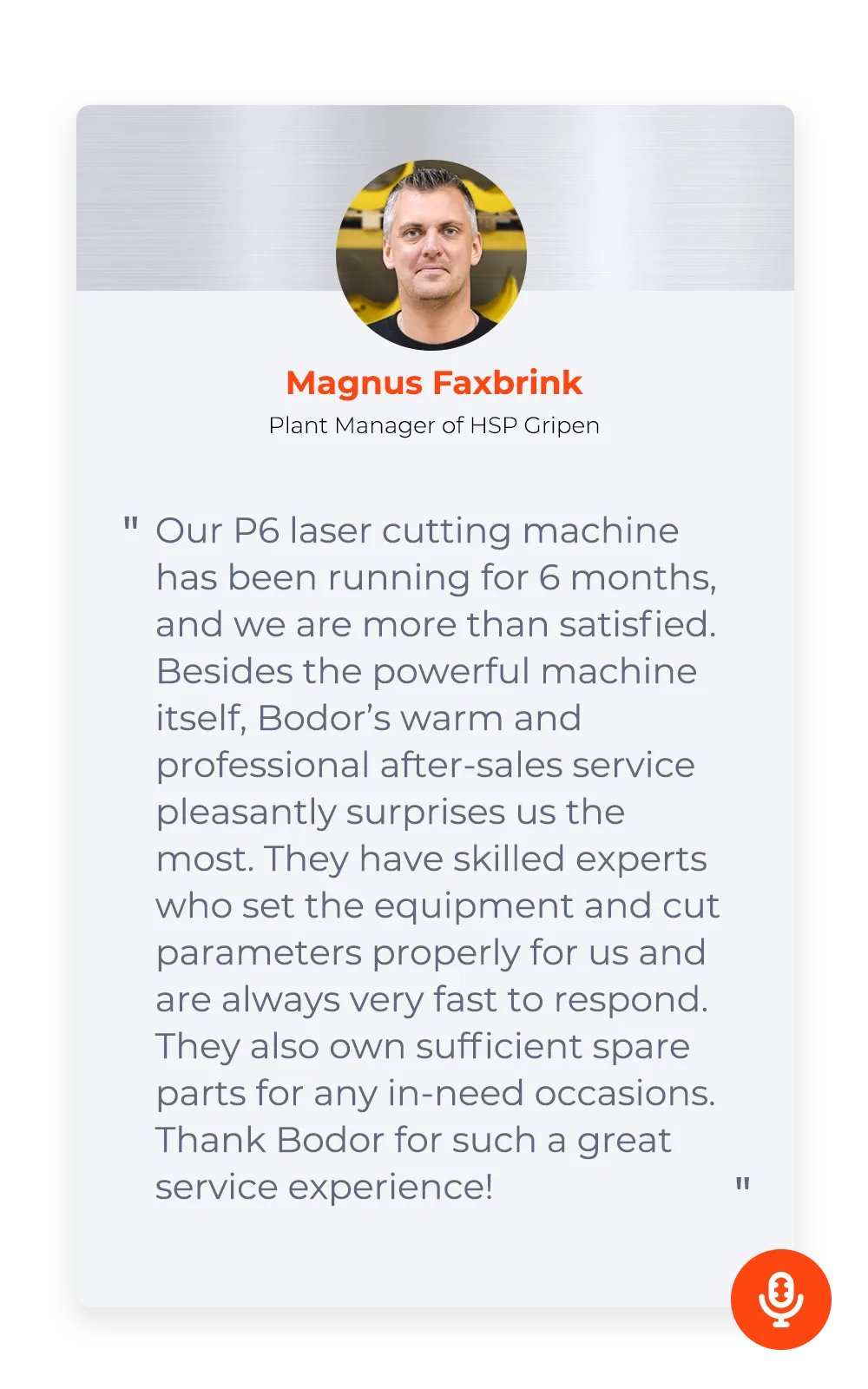

"We have a 260amp plasma cutting machine for Hardox steels, but its precision is much less than satisfactory," said Faxbrink, the plant manager of HSP Gripen. He explained that the plasma cutter has a large hole tolerance of 0.4mm, often yielding deformed holes that require manual grinding.

Evident tapers also comprised the cut quality of grapple components and increased labor and material costs. It’s hard to avoid them when using a plasma cutter because many factors, such as cutting direction, speed, and consumables’ condition can lead to tapers. The company wants processed steel plates with 90° squareness, not with tapers that have two unparallel edges in exaggerated angularity.

High-quality 40mm Steel Plate Laser Cutting Sample by Bodor P Series

It was Bodor’s outstanding sample-cutting demonstration that impressed Gripen. "We would ask them to cut similar steel plates on-site to see the actual performance when laser cutter providers were promoting their machines," added Faxbrink. "Bodor used its P series to demonstrate, and it only took about 30 seconds to cut off a 40mm carbon steel plate. We also observed the cut surface and cut section. Clean cuts, small kerf, and no taper! That’s definitely something the plasma cutter cannot achieve."

Gripen finally adopted a P6-22kW model, considering the hardness, thickness, and desirable effects of the Hardox plates. P series represents a high-performance metal sheet laser cutting feature, catering to all manner of processing needs and scenarios. Meanwhile, 22kW laser power allows cutting materials above 30mm with a much faster speed and higher cut quality.

P6 Model Achieves 0.05mm Laser Cutting Precision and "Zero" Taper

HSP Gripen now can create consistent round holes with the BodorThinker software in batch processing. Compared with the 0.4mm precision of plasma, the P6 laser cutting machine achieves a superior precision of 0.05mm, indicating an 8-fold enhancement. This not only improves Gripen’s grapples to a more excellent quality but also effectively utilizes materials.

Faxbrink said that he barely saw tapers showing on the processed plates after employing Bodor’s machine. The workers used to take a very long time to burnish the plates, trying to reduce tapers as much as possible. By cutting out this step, Gripen manages to save considerable labor costs and materials together.