The very first 22kW laser cutting machine in Europe

Optimal Solution to Enhance Efficiency and Upgrade Business

↓

Snijbedrijf Nauta B.V.'s Success Story

67%

Cutting time reduced

2×

Cutting capability

87%

More efficiency

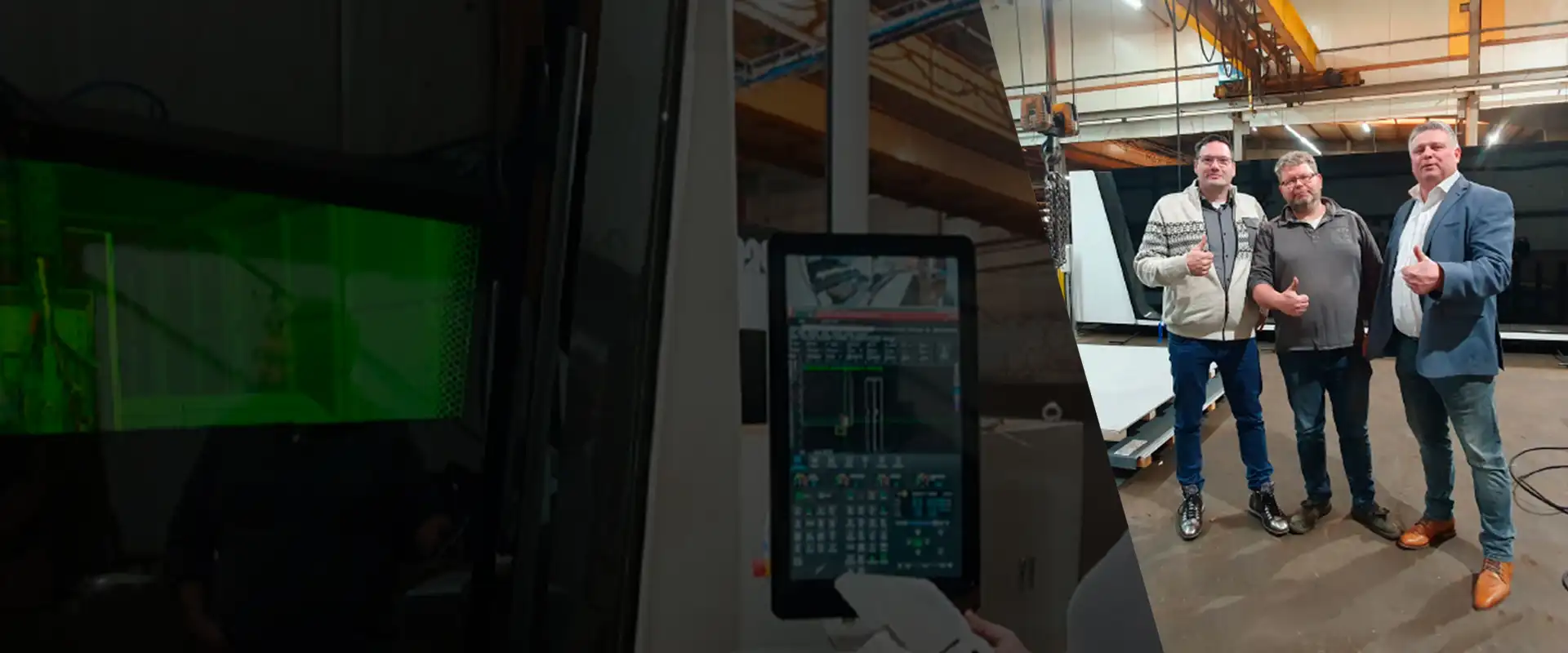

Established in March 2001, Snijbedrijf Nauta B.V. is a distinguished cutting company located in Sneek, Netherlands. With a strong commitment to excellence, Nauta specializes in the fabrication of metal structures and has been actively engaged in the cutting technology market. Catering to a diverse range of industries, Nauta offers cutting services including laser cutting, oxy-fuel cutting, waterjet cutting, and plasma cutting.

INDUSTRY

Metal Fabrication

DELIVERY TIME

Last Half of 2022

LOCATION

Sneek, Netherlands

Three Main Challenges Nauta Faced

As the market continued to expand, Nauta was exposed to quite a few challenges and obstacles.

The most knotty problem was how to minimize cutting expenses when accommodating diverse industries, such as agriculture, shipbuilding, and food processing. With a variety of materials to process, including steel, stainless steel, aluminum, cropper and brass, Nauta must carefully consider which cutting methods to invest in.

Previously, Nauta had been cutting materials up to 300mm thick. To grow their business, they’ve decided to shift the focus on materials up to 30mm thick, a task that cannot be fulfilled with oxy-fuel cutting approach.

Moreover, as competition intensified, Nauta was in sore need of a cutting solution that enabled them to serve an even broader market segment.

Bodor P Series-The First 22kW Laser Cutting Machine in Europe

After interacting with several Bodor clients to gather their insights, Nauta ultimately chose to purchase the Bodor P Series 22kW, featuring one-second edge detection , a camera system to recognize sheet material lying on the cutting table digitally, helping quick edge seeking and principal focus adjustment. This versatile machine is also equipped with automatic nozzle changing and one-clicking processing capabilities, making it competent for overcoming the challenges of cutting, diverse materials, reducing costs, and expanding market. Notably, it is the first 22kW laser cutting machine in Europe. Before it, there were almost only low power machines, such as 3kW and 6kW.

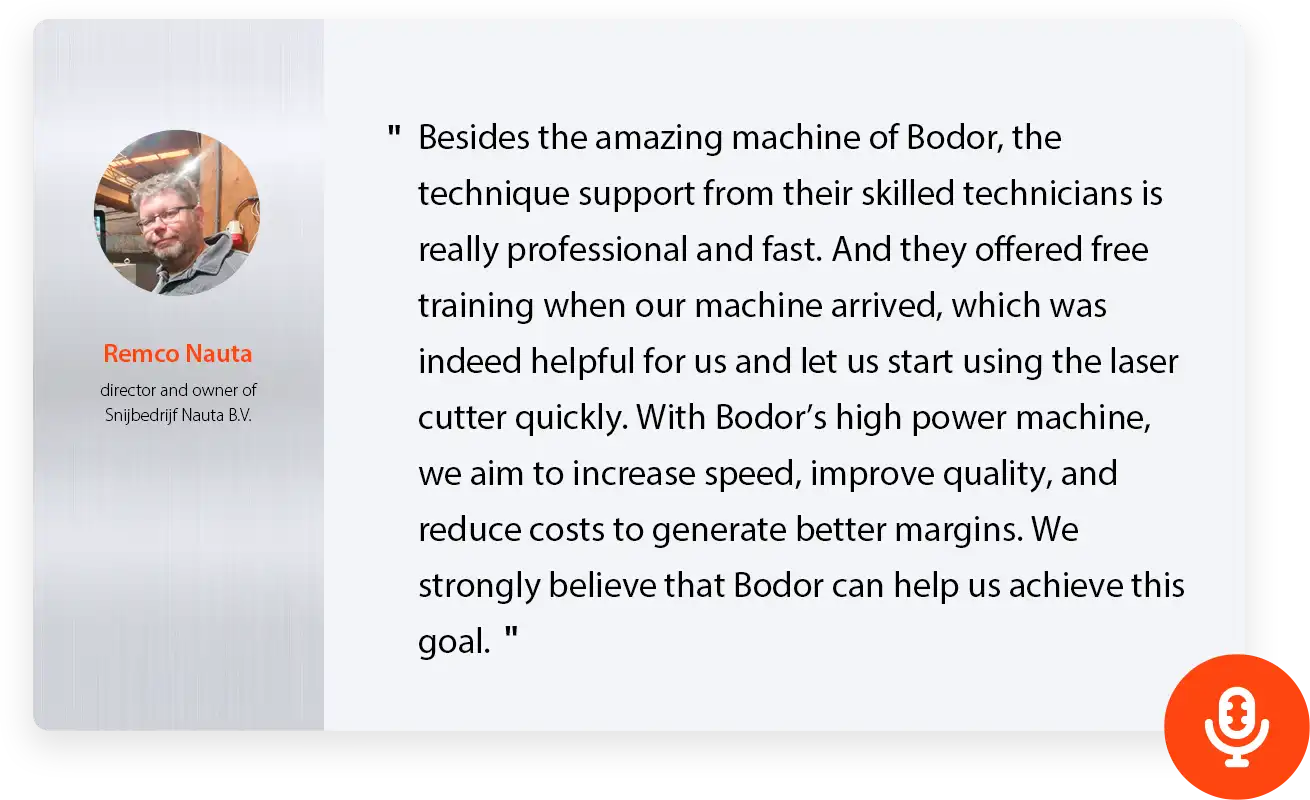

To ensure ongoing production stability, Nauta later acquired a second laser head from Bodor. “Nauta aims to maximize the machine’s potential in terms of thickness, speeds, and overall quality. We are going to attempt things that others might hesitate to try”, said Remco Nauta, director and owner of the company.

Great Improvements and Satisfying Cooperation

Under the help of Bodor ultra-power laser cutting machine, Nauta has revolutionized its shipbuilding process. With a cutting speed of 20 meters per minute, cutting time has been reduced by 67%, from 45 to 15 minutes. Previously, it took two employees two and a half days to cut steel boats, but now one and a half employees can complete the job in just one day on average. Also, Nauta used to cut 20 plates with one tank, but now they can cut 40 plates with the same tank.