Bringing Production and Services In-house

Malaysia’s ABC Engineering Overcomes the Lead Time and Quality Challenges with Bodor A3 Fiber Laser

ABC's Success Story

80%

Lead time reduced

2X

Product quality improved

50%

Costs saved

Located in Puchong, Selangor, ABC Metal Works Engineering (ABC) excels in sheet metal processing. The company, led by a highly skilled and dedicated owner, offers both standard and custom solutions to meet diverse customer needs.

INDUSTRY

Metal Fabrication

INSTALLATION TIME

2021

LOCATION

Selangor, Malaysia

Uncertain lead time and product quality caused by outsourcing

ABC is a well-known metal fabricator that has been providing high-quality metal products for years. However, outsourcing let to unpredictable lead times and inconsistent product quality, risking their reliability.

The lead time for their products was unpredictable, and the quality of the products was challenging to manage. These posed a considerable risk to their reputation as a trustworthy metal fabricator. The outsourcing costs were also excessive, adding to the financial strain on the company.

In response to these issues, ABC recognized the need to acquire a metal processing machine in order to bring production and services in-house.

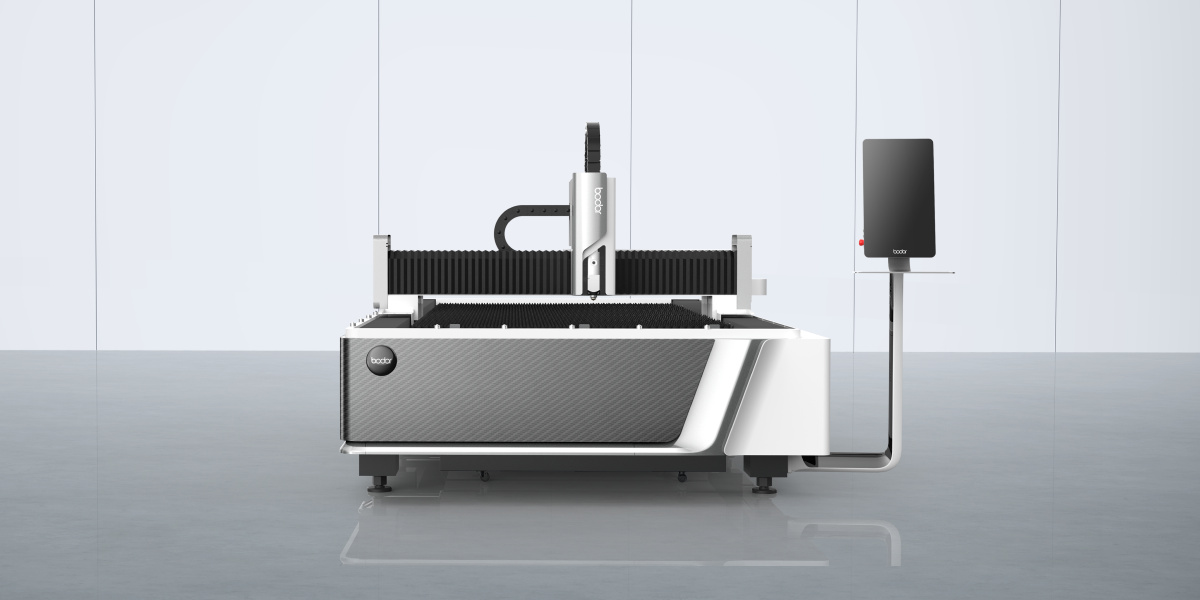

Transforming to in-house production by adopting Bodor A3 fiber laser

When searching for options online, they discovered Bodor laser solutions via social media. Attracted by the advanced technology, they contacted Bodor's sales team and scheduled a visit to see the machine's performance first-hand.

During the visit, ABC's representatives were impressed by the advanced features of Bodor's laser cutting machines, particularly the A series' high-speed cutting and easy operation. They found that the machines were reliable, efficient, and had the capacity to solve all the problems they were facing with outsourcing.

After a thorough evaluation, ABC invested in a Bodor A3 fiber laser cutting machine to improve overall productivity.

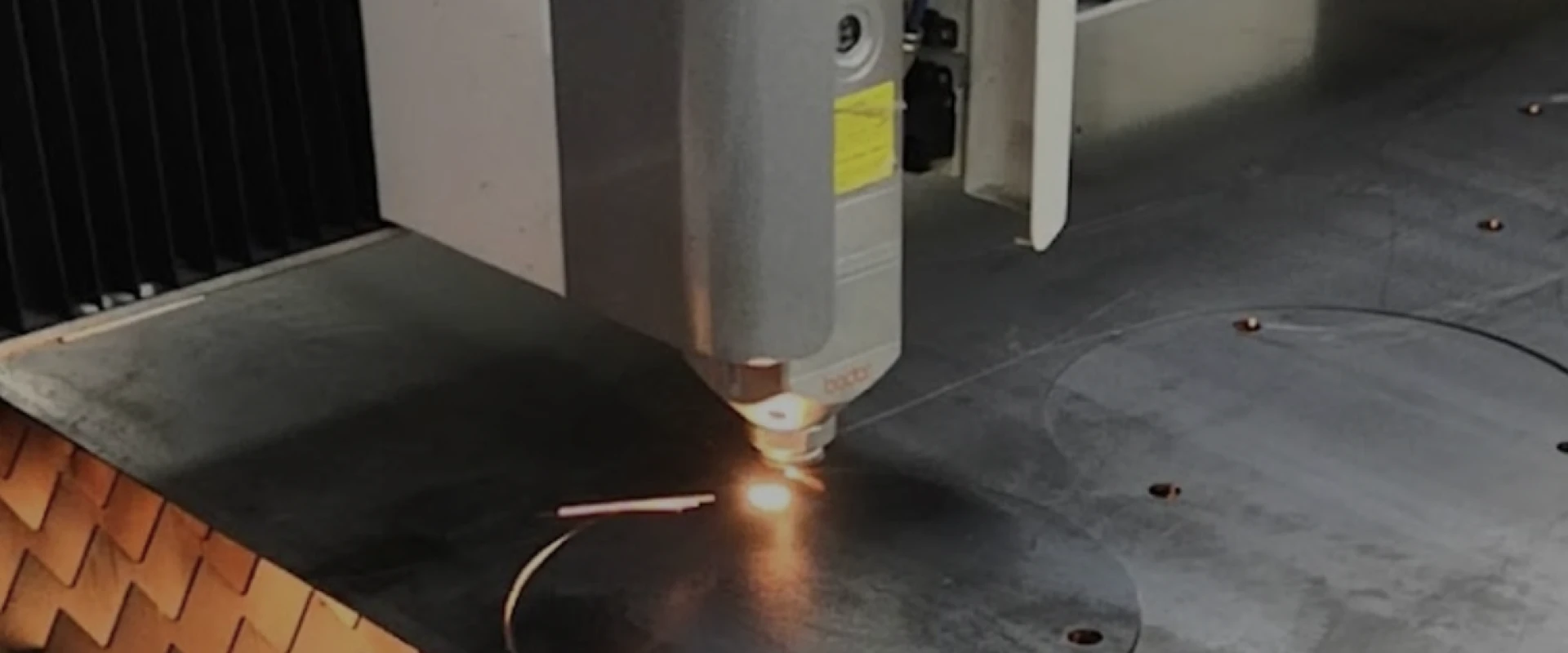

Better control over lead time and product quality while halving costs

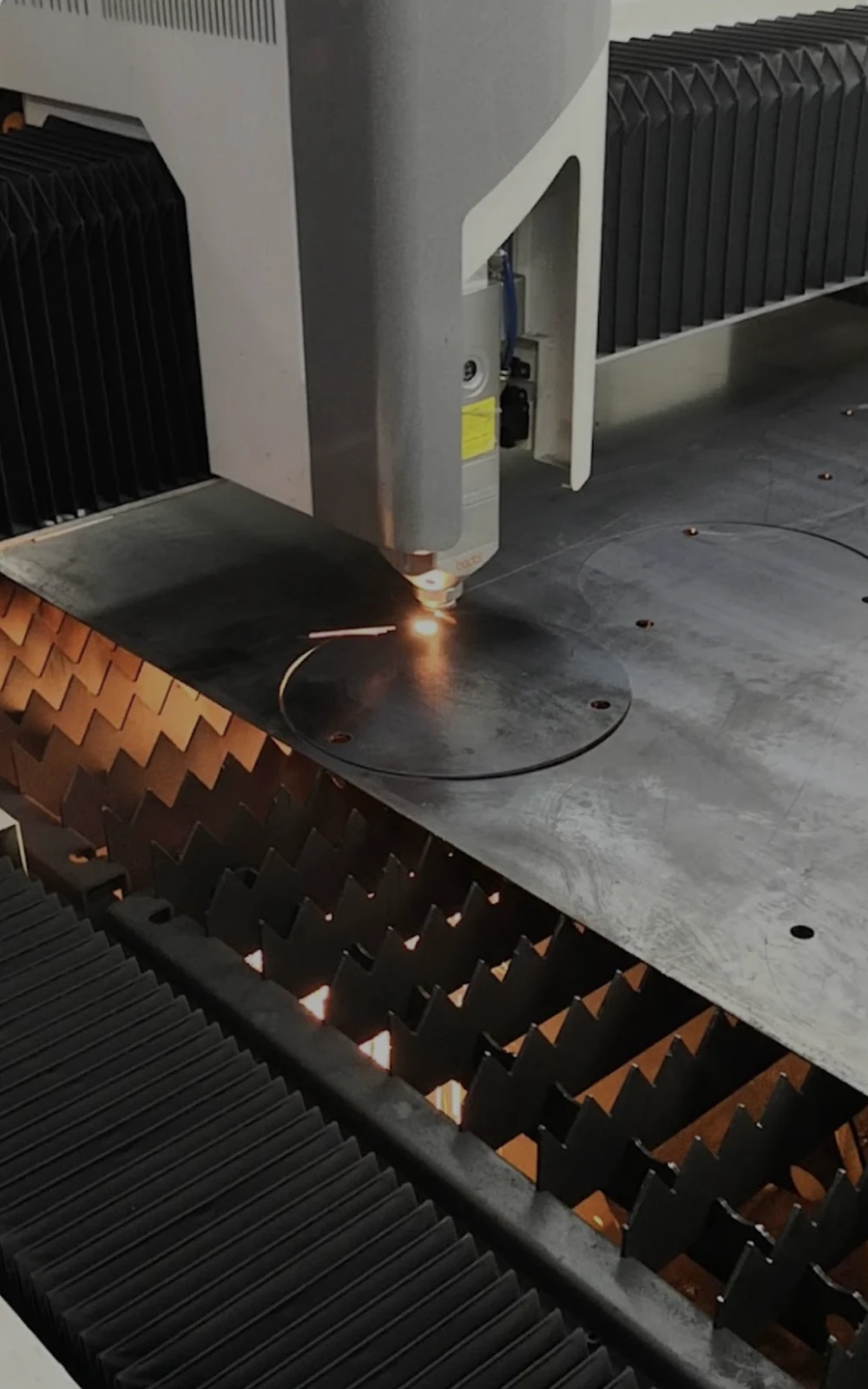

The investment in the Bodor A3 machine brought remarkable results. ABC achieved significant advancements in cutting speed and quality. The company can now test and cut its products anytime, giving it control over product quality and delivery time. Furthermore, ABC no longer needs to pay high outsourcing fees, leading to a substantial reduction in overall costs.

The A3 machine has become an integral part of their production process. Notably, ABC has even customized a protective cover for the machine to ensure it remains in good condition and continues performing as expected, which highlights the value of the investment.