A Strategic Upgrade from Plasma Cutting to Laser Scanning Cutting

Biadała's Journey of Efficiency and Quality Enhancement with Bodor Laser Cutting Machines

Biadała’s Success Story

70%

Cutting quality improved

50%

Processing efficiency increased

2x

Cutting speed soared

Z.P.H.U. Biadała Sp. z o.o., established in 1986, boasts rich experience in central heating boiler production. The company has been steadily broadening its reach in serving the European market. With its outstanding products, Biadała stands as a top-tier boiler manufacturer in Poland. With the commitment to provide high-quality products and services to its clients, Biadała won the Consumer Award in 2020.

INDUSTRY

General Equipment

INSTALLATION TIME

2023

LOCATION

Kórnik, Poland

Outdated plasma cutting bringing quality and speed challenges to Biadała

Biadała, a boiler expert with decades of experience, used to encounter a production bottleneck in quality and speed. The root cause of these challenges lies in using the traditional plasma cutting method.

The outdated cutting method resulted in imprecise cuts and rough edges. The lousy quality led to inconsistencies in the dimensions of the boiler components. As a result, Biadała’s assembly processes were often hindered, and required additional time and effort in secondary processes.

Additionally, the inefficient plasma cutting struggled to keep pace with the increasing demands for faster production cycles. Slow cutting speed and frequent downtime further exacerbated the challenges faced by Biadała, which impeded their ability to fulfill orders promptly and meet customer expectations for timely delivery.

The limitations of plasma cutting compromised the quality of Biadała's boiler components and posed significant obstacles to achieving efficient and cost-effective production processes.

Upgrading to Bodor fiber laser cutting machines after witnessing them at an exhibition

Biadała realized it was time to upgrade its cutting equipment to overcome these challenges and maintain its leading position in the industry.

Therefore, Biadała attended a manufacturing technology exhibition, where they met Bodor Laser. The excellent performance of Bodor machines immediately caught their attention, especially those equipped with laser scanning cutting functions. The laser scanning cutting machine is a new category launched by Bodor in March 2022. With dynamic facula cutting, the beam locus covers 30m for every 1m cut, significantly increasing the cutting capacity.

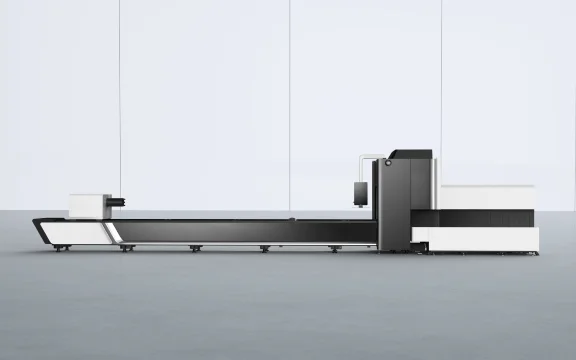

Biadała was Impressed by the remarkable performance of Bodor machines at the exhibition. Therefore, they strategically acquired the T2 3kW cutting machine and the P3 6kW cutting machine with laser scanning cutting function. Biadała aimed to elevate the quality and precision of production processes.

Elevating cutting quality and efficiency with Bodor P3 and T2 laser cutting machines

The adoption of Bodor machines has revolutionized Biadała's processing. They have witnessed a significant boost in the product’s quality and efficiency.

In addition to laser scanning cutting functions, Bodor machines are equipped with the state-of-the-art BodorGenius laser head, renowned for its perfect execution of precise cuts. Thanks to BodorGenius, the cut edges are smooth and burr-free without the need for time-consuming secondary sanding.

Moreover, the P3 machine's innovative functions, such as one-click processing and one-second edge finding, facilitate a seamless workflow. These intelligent functions result in optimized processing efficiency and enhanced productivity for Biadała.

Through the incorporation of Bodor's advanced machines, Biadała has effectively addressed previous challenges and enhanced its capacity to tackle precise components. Biadała successfully retains its reputation as a high-quality and reliable boilers provider, thus solidifying its position as an industry leader.