Bodor Tech Blog

Trending and helpful laser knowledge for your success

Enhancing Metal Service Centers - The Power of Laser Cutting in Value-Added Services

Imagine a technology that can transform metal service centers into hubs of precision and efficiency, offering additional value to their customers. Enter laser cutting—a game-changer redefining the potential of value-added services.

As a vital bridge between steel mills and end industries, service centers are embracing innovative processing methods to deliver enhanced value-added services and to stay ahead of the competition. Laser cutting, in particular, is emerging as an efficient method for producing high-quality metal products.

Get metal service center whitepaper

Looking to gain insights into metal service centers? Download the Bodor industry whitepaper now and get your hands on a comprehensive guidebook!

What are value-added services?

A metal service center generally manages metal material for smaller companies without large amounts of storage space. More importantly, metal service centers provide valuable benefits to businesses of all kinds through their range of value-added services. By outsourcing processing work to these centers, companies can avoid the need to invest in bulky equipment. With skilled metal professionals and expert equipment management, these service centers ensure that companies receive the required high-quality metal treatment.

Value-added services often involve a wide range of operations, which may include:

Tube material

Cutting services

Cutting off: Cutting off tubes to exact specifications with saw/flame cutting

Beveling: To meet welding, safety, or aesthetic needs

Profiling: Forming specific profiles or shapes on tubes

Other services

Threading: Threading pipes up to 6 inches in diameter

Protective coating: To prevent rust and moisture

Testing: Comprehensive quality testing

Project management: Tracking orders to ensure accuracy and timely delivery

Sheet material

Shearing: Cutting sheet metal to size out of a larger plate

Circle shearing: Producing circular blanks from sheet metal

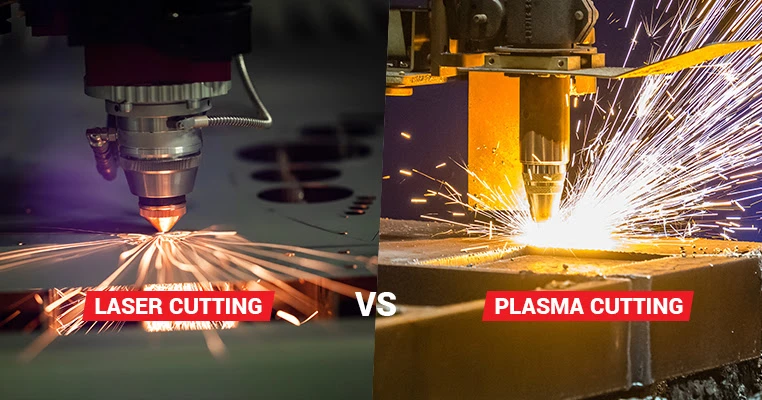

Plasma and flame cutting: Thermal cutting methods that cut sheet metal into specific shapes and sizes

Coil material

Cut-to-length: Cut coils to customized lengths according to specific customer specifications

Slitting: Longitudinal cut of the coils to the specified width

Blanking: Producing flat sheet metal from coil stock with a coil blanking line

Laser cutting applications

Among the various processing methods, laser cutting technology is a superior choice for achieving unparalleled accuracy and efficiency. This technology has revolutionized traditional processes, enhancing capabilities in cutting off, beveling, and pipe profiling.

Sheet metal cutting

Metal service centers typically purchase bulk steel from reputable raw material suppliers. After that, they cut the steel to the required lengths to meet standards or directly create the specific parts requested by their customers, ensuring that their customers receive the highest quality products.

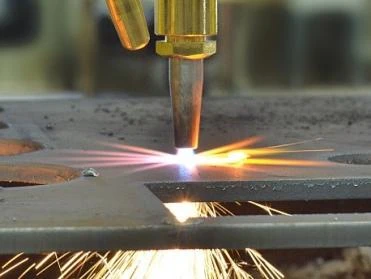

The cutting off process involves a high level of precision and quality to ensure that the finished product meets the needs of its customers. In this case, laser cutting stands out as an ideal choice to replace traditional metal cutting tools, such as shearing machines, flame cutters, and plasma cutters.

Laser cutting replacing plasma cutting

Structural steel cutting

Laser cutting can effectively replace saws and flame cutters in structural steel cutting due to its precision, efficiency, and versatility. Laser cutting machines can handle complex shapes and intricate designs that are challenging for saws and flame cutters to achieve.

The special structural steel laser cutting machine, Bodor U10 Pro, can effortlessly handle ultra-long H-beams and I-beams up to 13,500mm, making them well-suited to meet every need of fabricators. These machines can perform not only simple cutting but also various processes like punching, notching, and beveling, all in one machine.

Beveling

Beveling is a versatile process that is used to meet various requirements, including welding, safety, and aesthetic needs. However, traditional bevel tools, such as handheld flame cutting, often result in rough edges that require secondary grinding. This process not only incurs high labor costs but also poses significant safety hazards to operators. Additionally, the precision of these cuts is typically poor, with inconsistent angles that can affect the quality of the final product.

Laser cutting is an excellent choice for producing high-precision bevel cuts in +/- 45 degrees and in various shapes, such as V-cut, A-cut, Y-cut, X-cut, and K-cut. Laser cutting machines can efficiently produce clean, precise, and intricate bevel cuts on a wide range of materials, making them an efficient and reliable option for metal service centers.

Bodor core technology: Excellent bevel cuts

Pipe profiling

Pipe profiling, also known as pipe cutting, is a manufacturing process that removes material from a pipe or tube to create a desired profile. This process is carried out to achieve a specific profile or shape, such as straight cuts, miters, saddles, and midsection holes.

Laser cutting has emerged as an efficient and cost-effective method to profile pipes, offering several advantages over traditional methods. Laser cutting technology makes pipe profiling more accurate and reliable, thus increasing the overall efficiency of the manufacturing process.

Bodor T series performance tube laser cutting machine

In summary, with its unmatched efficiency, accuracy, and versatility, laser cutting empowers metal service centers to deliver customized solutions faster and more effectively. By harnessing cutting-edge technology, service centers can exceed customer expectations, setting a new benchmark for excellence in the industry.

It's time to transform your value-added services with Bodor's cutting-edge laser solutions! For more information about Bodor laser cutting machines, please contact our sales.