Bodor Tech Blog

Trending and helpful laser knowledge for your success

5 Laser Cutting Application Trends in Metal Furniture Manufacturing Industry for 2024

Metal furniture, the perfect option for the trending decoration styles in recent years, like industrial loft style and light luxury style, is grabbing consumers’ attentions these days. It also has excellent corrosion resistance, water resistance, environmental friendliness and other properties, which make it ideal for furniture manufacturing.

As the metal furniture manufacturing industry continues to thrive, the integration of laser cutting technology is reshaping various categories, offering innovative solutions and unparalleled design possibilities. Let's explore the laser cutting application trends in the metal furniture manufacturing industry for the year 2024:

1. Boost productivity, cut costs

The metal furniture industry competition is intensifying and customer demands are diversifying. Manufacturers must enhance production efficiency and cut costs to stay ahead.

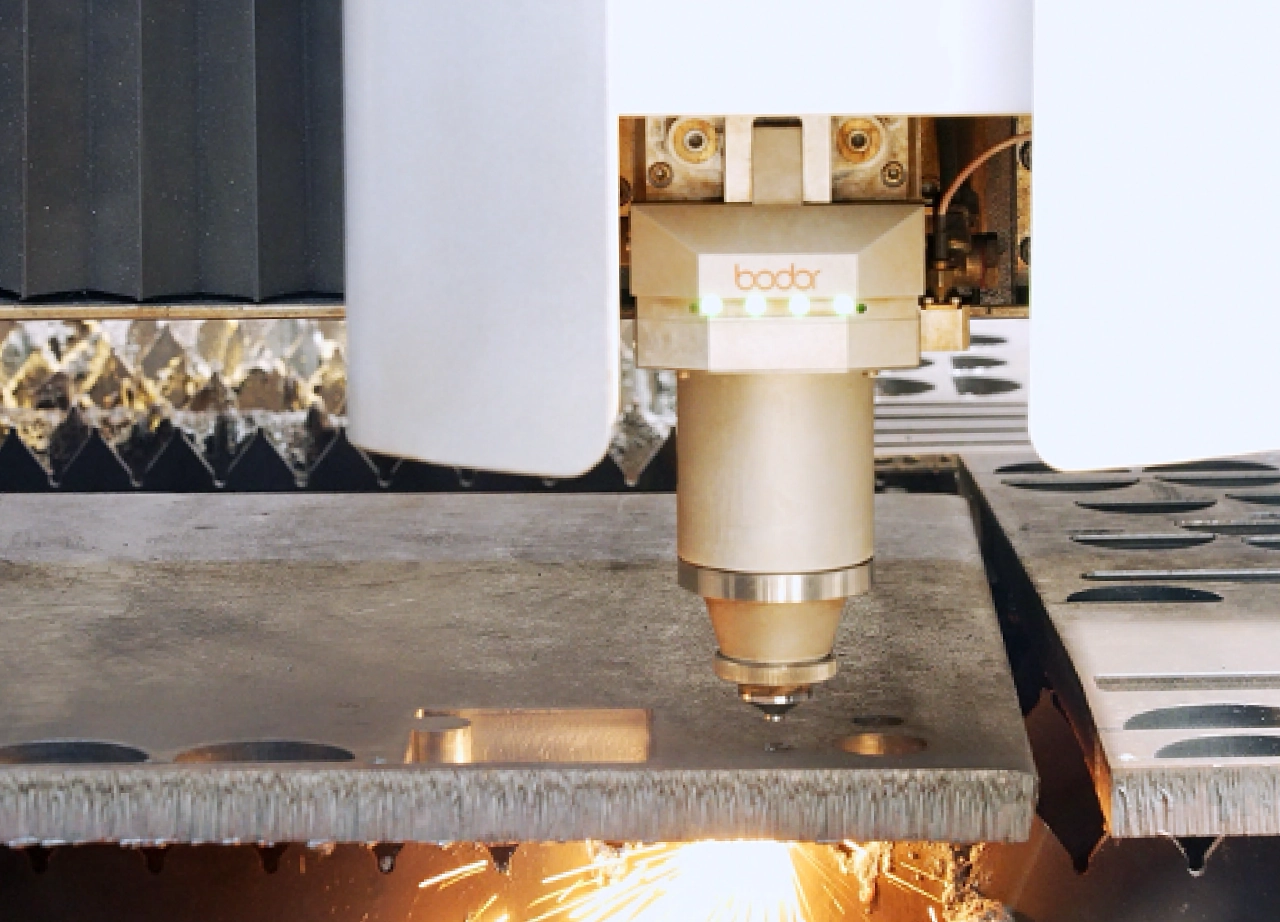

Fast, precise, and continuous cutting process feature enables laser cutting equipment to save time and materials. The production quality and stability hindered by manual operations and errors can even become much enhanced with intelligent automation devices.

2. Satisfy rigorous processing demands, guarantee top-notch product quality

To meed the ever-evolving demands of metal furniture design, manufacturers needs higher standards of processing accuracy and product quality.

Laser cutting allows fine and intricate cutting of various metal shapes and sizes. A laser cutter not only makes product test easier, but also avoids defects like deformation, burrs, and cracks, for mass production. As a result, metal furniture manufacturers can easily captivate the hearts of customers with impressive creativity and excellent quality.

3. Offer customized product design

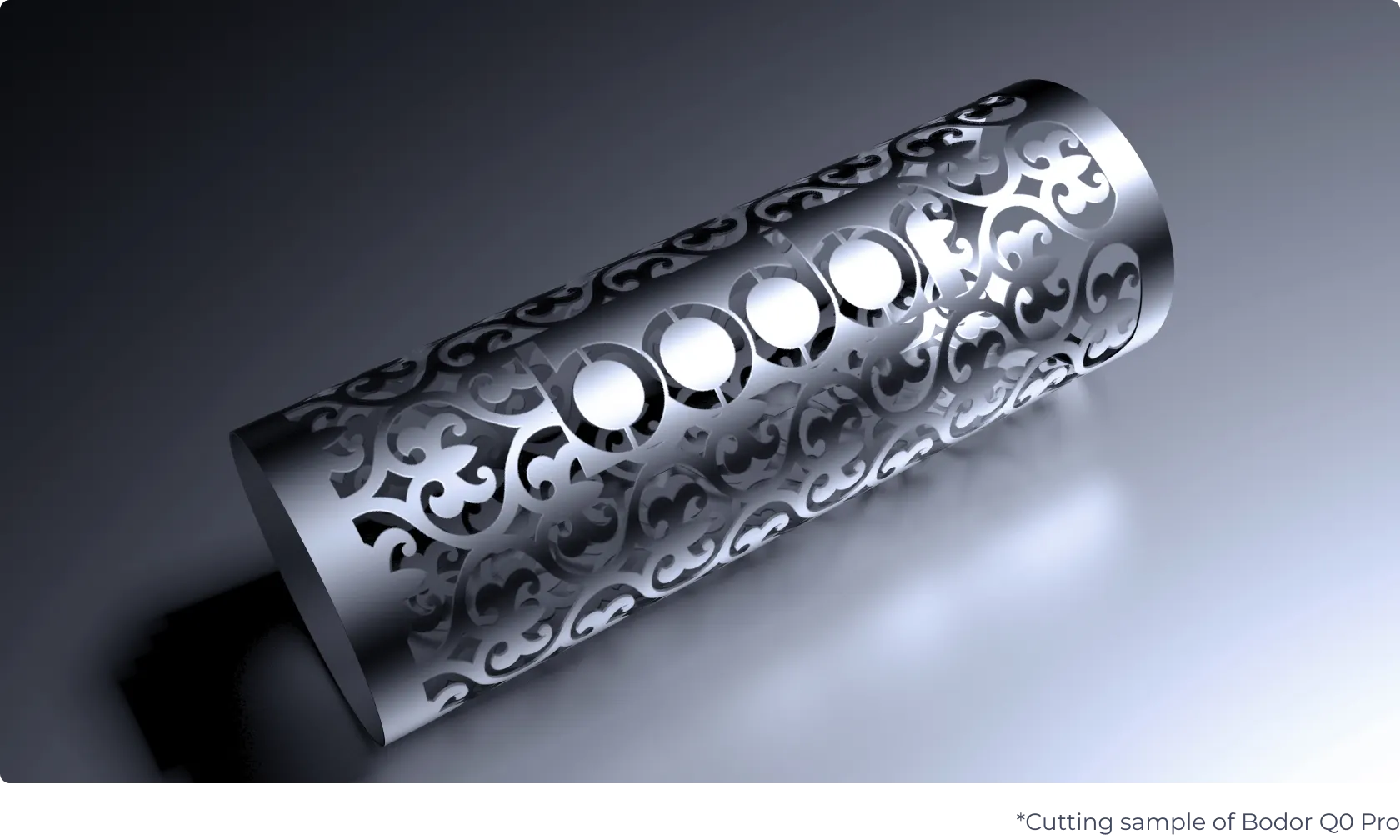

The rise in consumer demand for personalized and custom-made metal furniture challenges manufacturers to offer a wide range of product types and styles.

The convenient process to bring metal materials into any desired shape and pattern helps laser cutting equipment cater to different customers’ personalized needs. Additional advantages, such as wide ranges of processable metal types and thicknesses, intelligent nesting, and narrow kerf width, also ensure the adaptability of different product functionalities and aesthetic requirements.

4. Implement eco-friendly processing methods

Environmental protection and energy conservation are gaining momentum in the world, and the metal furniture industry also needs to align with the principles of sustainable development.

Laser cutting equipment achieves clean processing with less pollution, noise, or waste generation, reducing its environmental impact.

5. Prevent human and machine hazards

Industrial safety incidents are becoming more frequent and severe. The metal furniture industry must prioritize safety management and supervision.

The non-contact remote operation of laser cutting method minimizes direct personnel-machine contact and collisions. Laser cutter providers also enhances the protection to their product users by developing some thoughtful features including automated and intelligent fault diagnosis and alarm functions.

With the impressive growth projected for the metal furniture industry, manufacturers must embrace innovative solutions like laser cutting to capitalize on new opportunities and deliver cutting-edge designs that resonate with the ever-changing tastes of consumers. By harnessing the power of laser technology, the metal furniture manufacturing industry is set to redefine the furniture creation and elevate manufacturing efficiency to new heights.

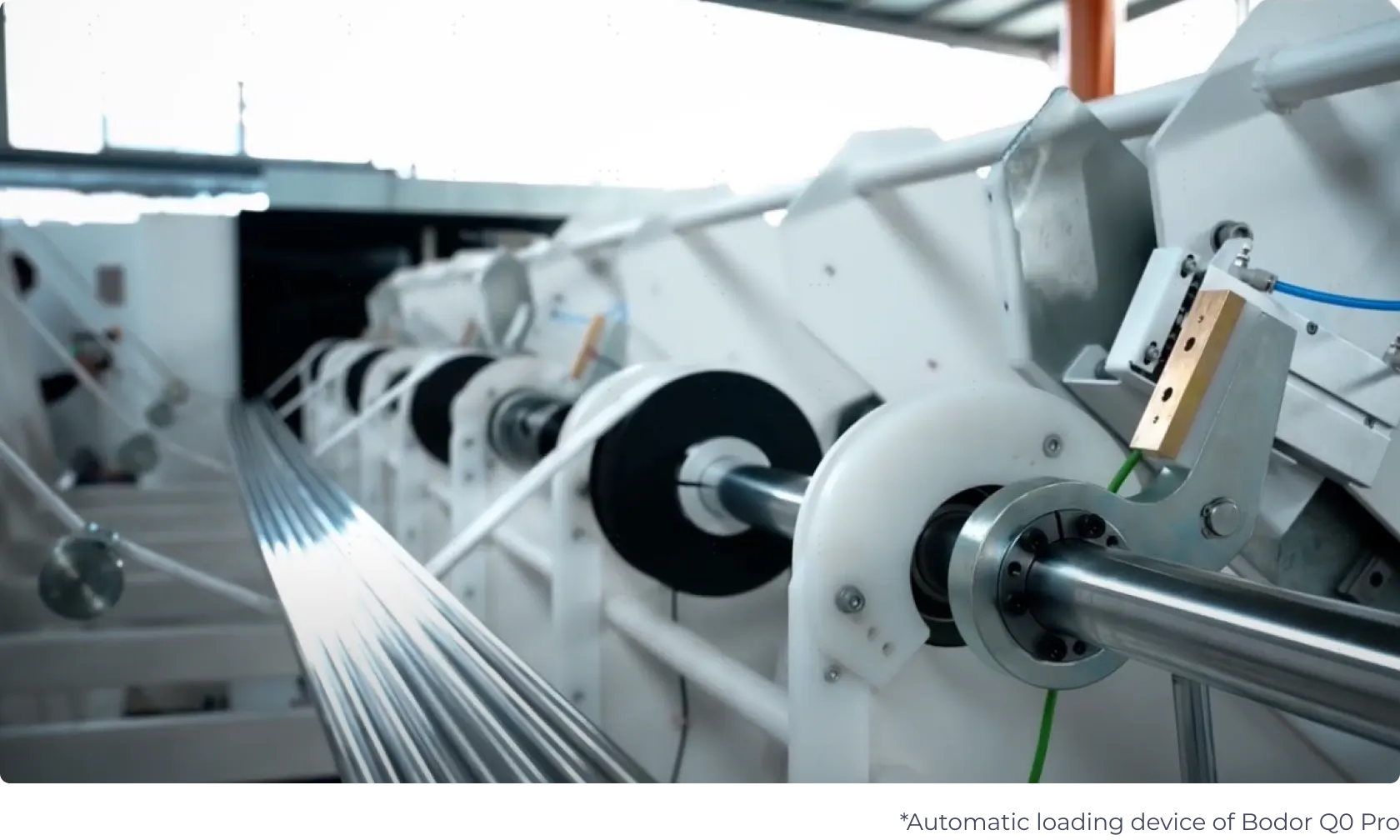

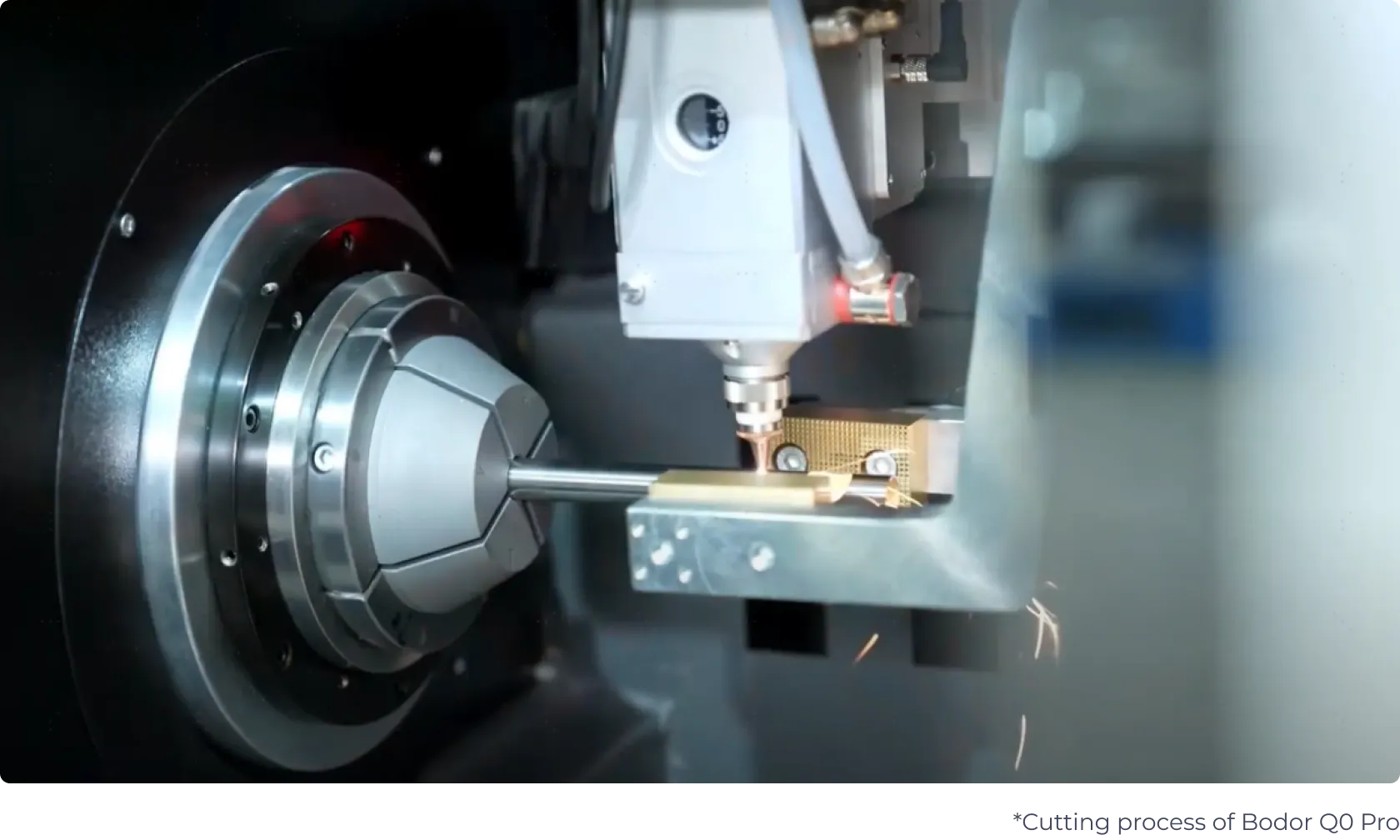

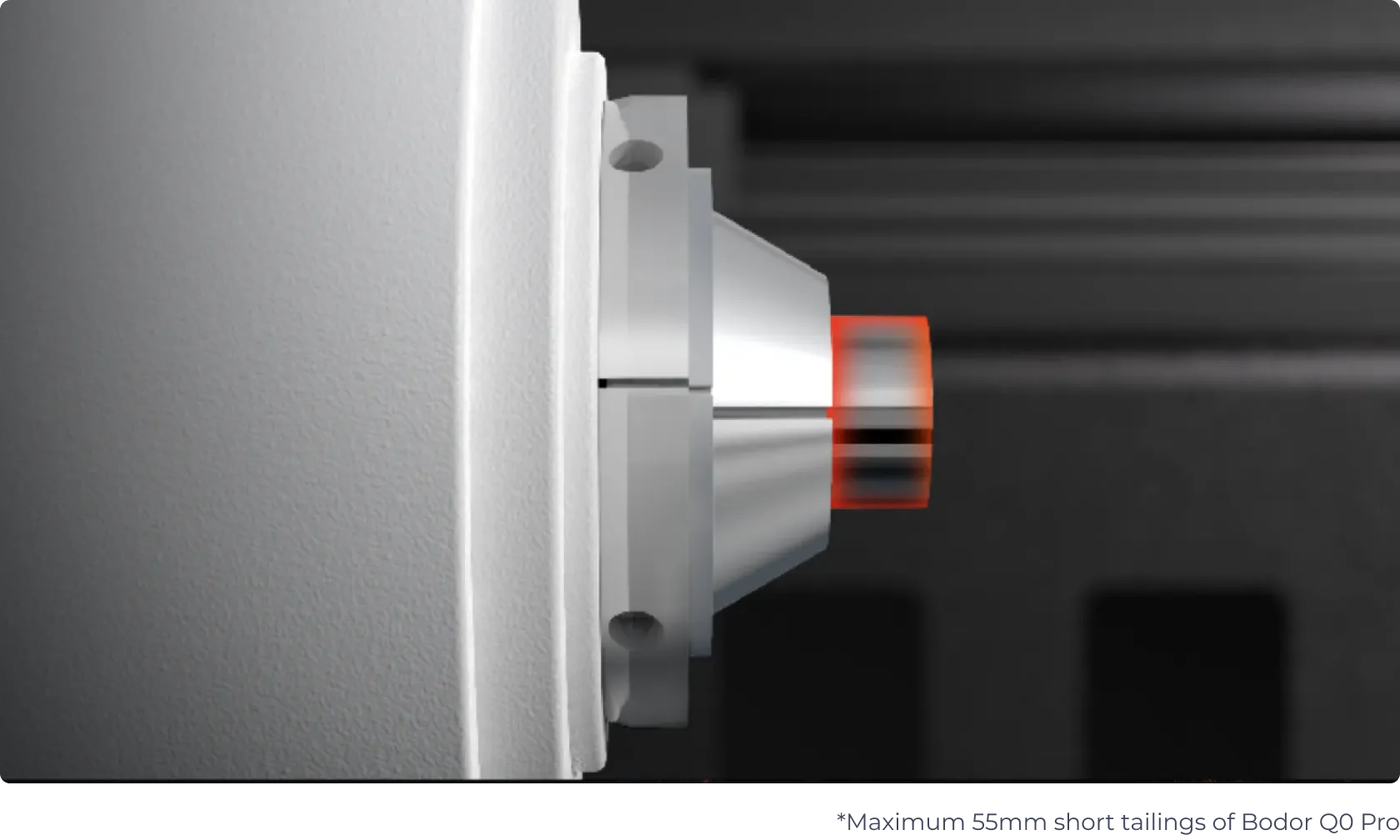

Bodor’s newest tube cutter, Q0 Pro small tube high-efficiency laser cutting machine, adopts fully automatic loading device, super-dynamic servo motor, and Bodor intelligent functions to support the easy and fast processing of 10-60mm small tubes, commonly seen for metal furniture manufacturing. Whether you’re looking to meet the growing demand for personalized designs or stay competitive in production cost and efficiency, Q0 Pro can get you covered.

One Bodor Q0 Pro customer, has been able to save its processing steps like sawing, punching, drilling, and grinding. This dramatically reduces the complexity of manual operation for its outdated equipment and cuts huge costs. Now with Q0 Pro, the production team helps the company produce 37% more products per month.

Learn more about the professional small tube high-efficiency laser cutting machine, visit the introduction page of Q0 Pro, and request a Q0 Pro demo now.