Bodor Tech Blog

Trending and helpful laser knowledge for your success

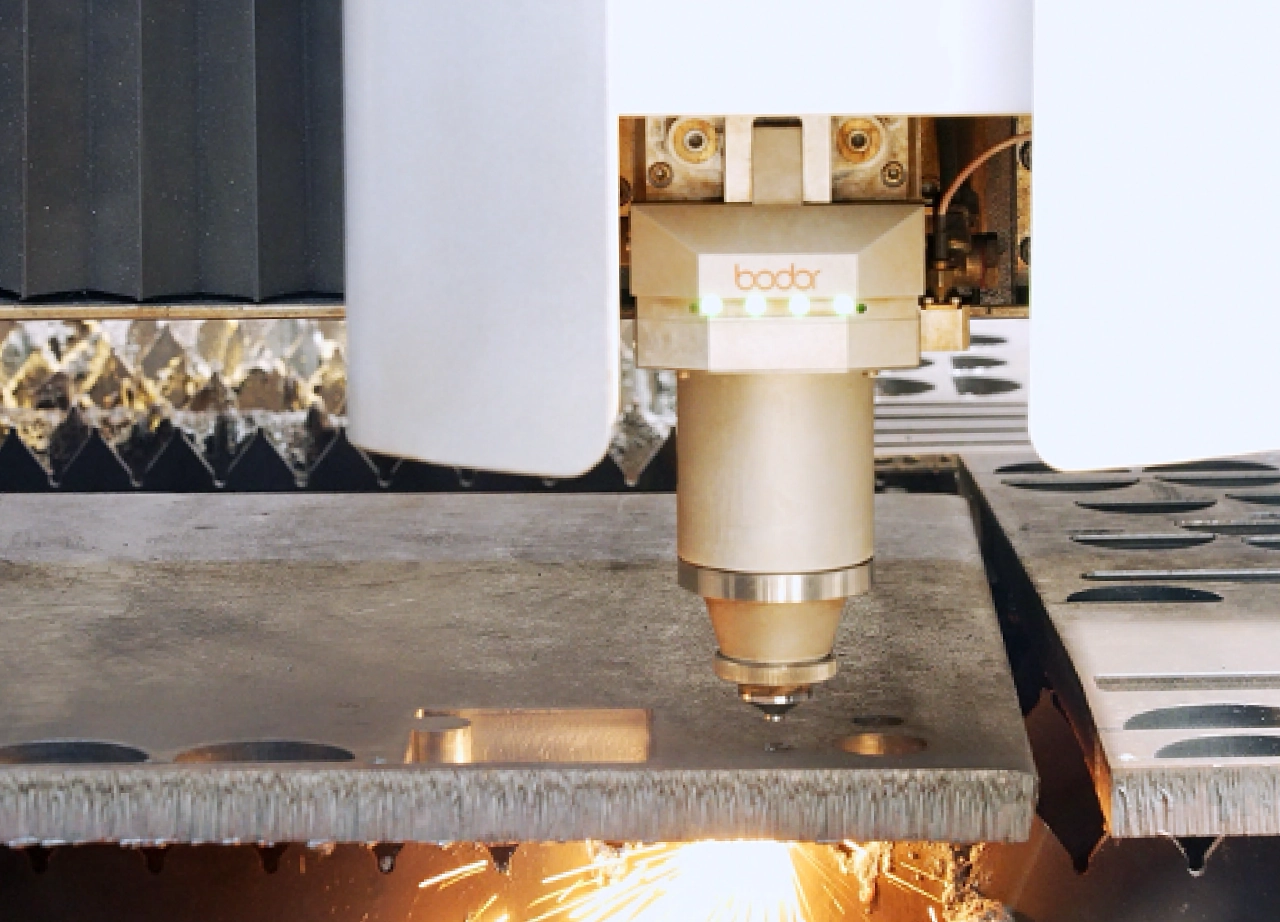

Bodor intelligent cutting application - Shining Cutting, no burrs for aluminum cutting

Laser cutting is now the most advanced technology to cut metal. When cutting aluminum alloy, burrs (metal slag) at the cutting edge which brings about a rough cutting surface often makes the manufacturer compelled to do secondary polish. This extended processing consumes a lot of time and additional processing costs. To help fix the industry point, we recommend you the new Bodor "Shining Cutting" technology.

Advantages of "Shining Cutting":

Shining Cutting is based on our newly developed device, "Saber". Compared with the previous Smooth Cutting, it is easier to operate. Besides, cutting quality, cutting efficiency, and cutting safety - all are better than normal cutting.

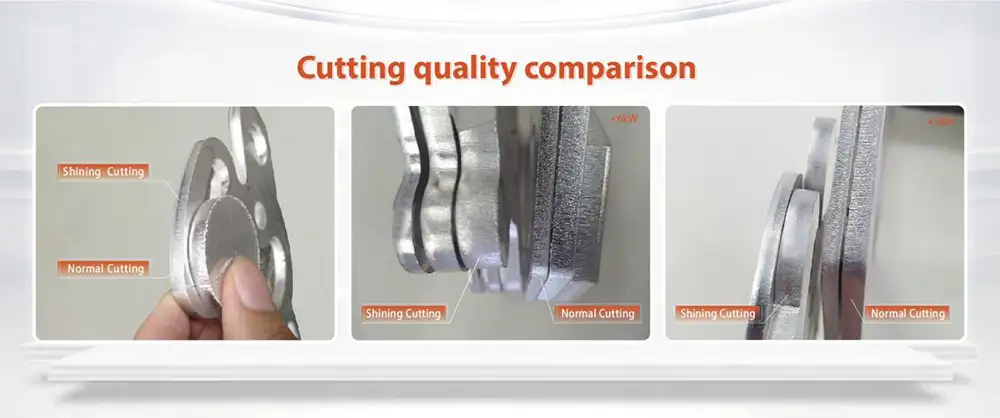

1. Better cutting quality

Shining Cutting guarantees that the cutting edge has no burrs and the surface is shining when cutting aluminum of different thicknesses with different power.

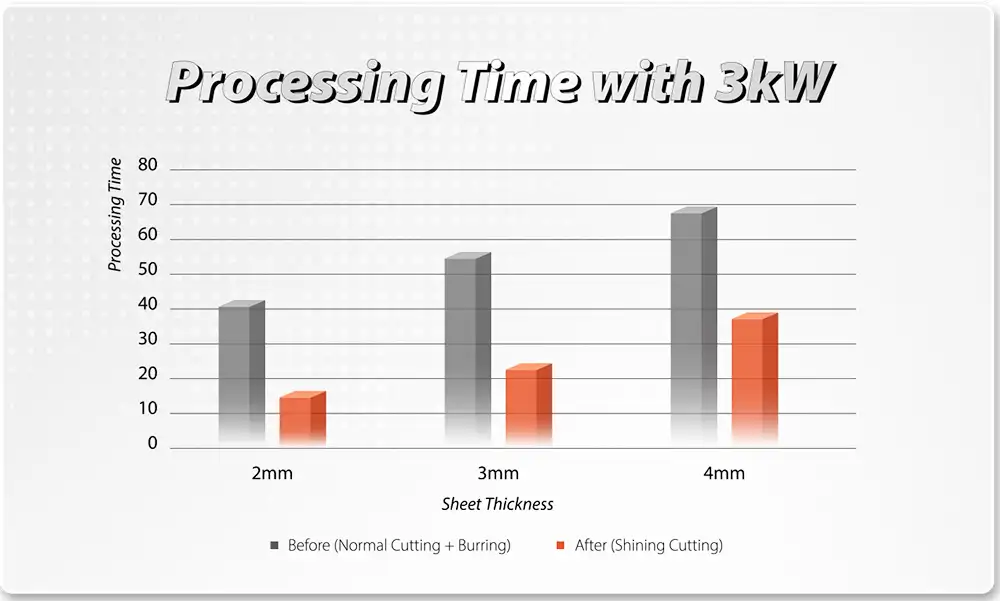

2. High cutting efficiency

Here we record the processing time of cutting 2mm, 3mm, 4mm aluminum sheets from the same batch before and after installation of Shining Cutting Technology (sheet area: 3000mm*1500mm; option 3kW). Before the installation, we use normal cutting and additional burring to insure that the cutting quality for each thickness is the same with that of Shining Cutting. As the chart shows, 30% to 50% time is saved by Shining Cutting after the installation.

3. Safe and environment-friendly

Workpieces cut by the normal cutting require secondary grinding. Dust explosion may happen because of the generation of powdered aluminum in this processing. However, Shining Cutting needs just one processing which still cuts qualified workpieces, thus the risk of dust explosion is reduced.

The Bodor Shining Cutting technology is applicable to all our metal sheet fiber laser cutting machines and metal tube machines.