Bodor Tech Blog

Trending and helpful laser knowledge for your success

Brand-New Intelligent BodorThinker Function - Cutting Parameter AutoMatch

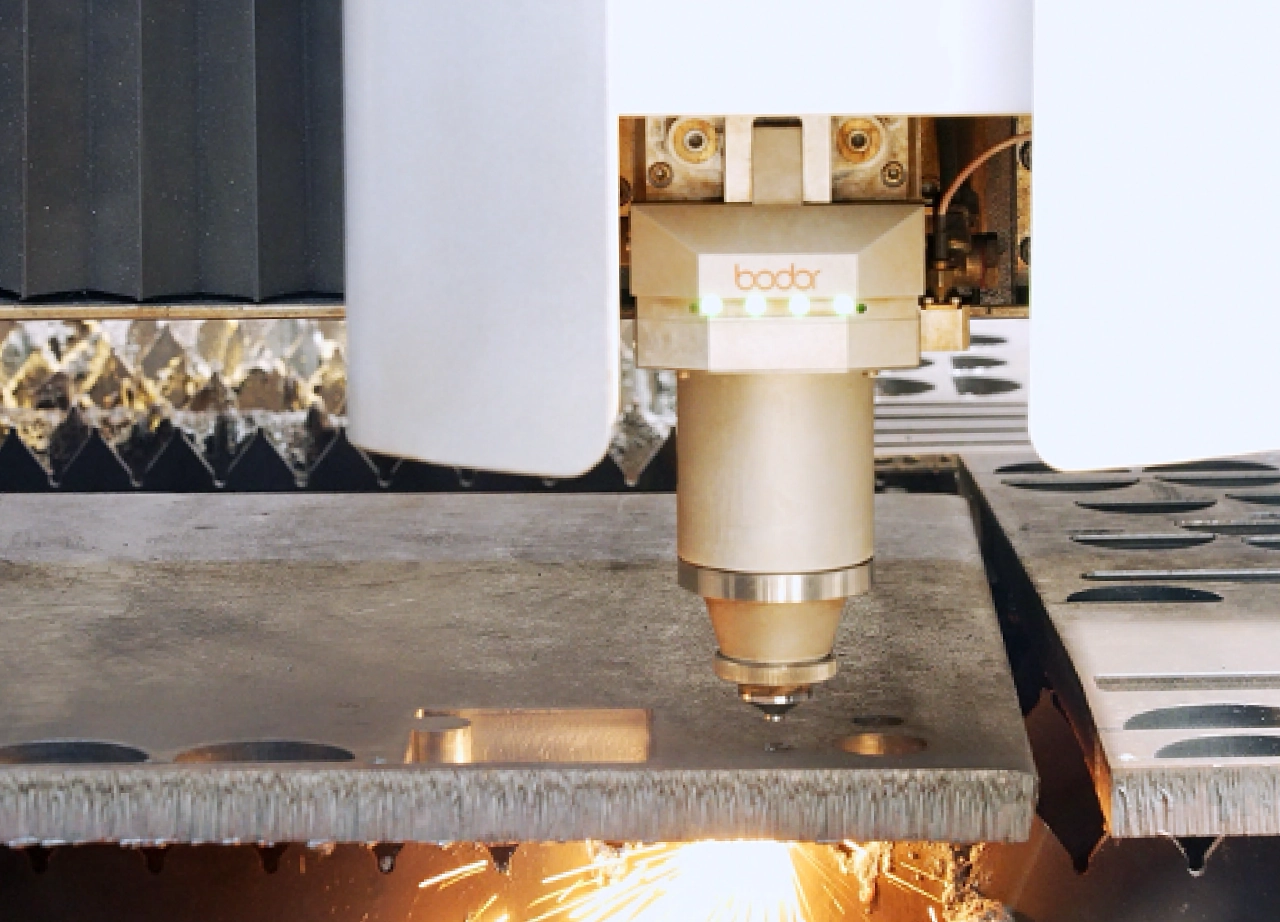

The accuracy of cutting parameters is extremely crucial to achieving consistent, high-quality laser cutting performance. However, when it comes to everyday machinery operations, manufacturers often face several problems with cutting parameter settings.

For starters, laser processing with incorrect parameters produces distortion in metal materials. Yet, inputting and adjusting parameters presents to be a common challenge for both beginners and experienced users. Traditional laser cutting process requires extensive hands-on training. But even with relevant skills and knowledge, obtaining the best cutting results can be very time-consuming as it usually takes multiple attempts of corrections. Repetitive test runs subsequently lead to increased wear and tear on components like laser heads and lenses. Frequent replacement of these delicate parts inflate production costs, posing a long-term obstacle to the widespread use and development of traditional laser cutting technology.

Here comes the good news: Bodor’s R&D team has come up with an innovation to tackle all these issues and revolutionize laser cutting operations.

The key to intelligent laser cutting

Bodor Intelligent Cutting Parameter AutoMatch is a new addition to the BodorThinker control system that helps users select laser cutting processes and adjust cutting parameters. It encompasses numerous advantages that can effectively eliminate operational defects caused by incorrect cutting parameters.

Higher production efficiency

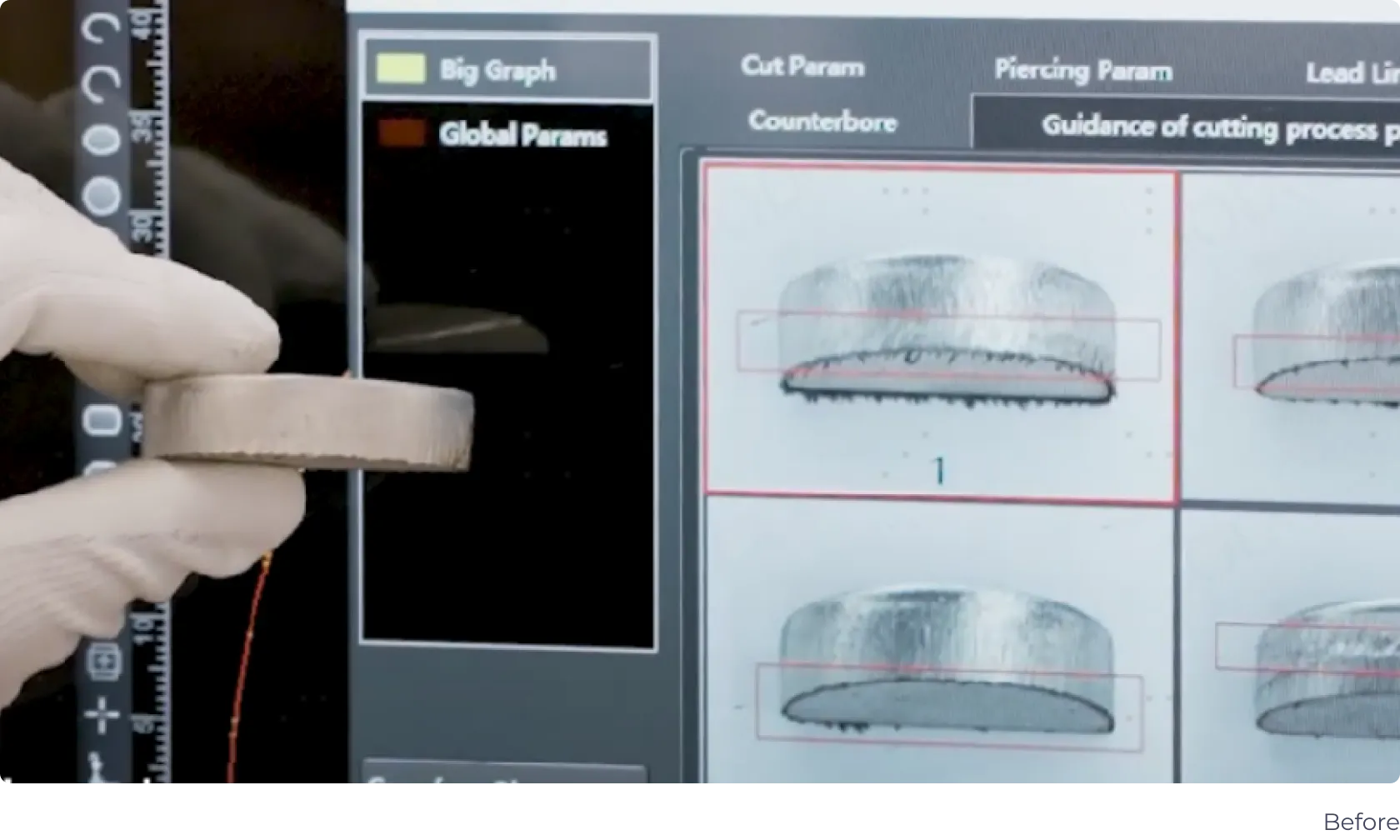

To facilitate the optimization of a cutting sample, Cutting Parameter AutoMatch will direct a range of pictures to the interface from the Bodor Laser Cutting Process Database, allowing users to adjust cutting parameters easily. Users no longer need to worry about positioning or changing cutting parameters, which drastically saves time, increases flexibility, and improves production efficiency. This advantage is incredibly helpful to manufacturers with heavy workload.

Lower learning curve

Another highlight of this innovation would be the minimal supervision and human intervention required. Without the need for manual adjustment, even beginners can create precise cuts on diverse kinds of materials. It also provides intuitive guidance for cutting process optimization, substantially reducing labor costs and lowering the learning curve of machinery operations.

Lower operation spending

In the meanwhile, Cutting Parameter AutoMatch cuts down part wear and equipment costs through automatic precision alignment, thus safeguarding critical components like lenses and laser heads to the largest extent possible.

Bodor’s Intelligent Cutting Parameter AutoMatch function has enabled all users to operate our products effortlessly. Navigation of is pretty easy, too. Let’s break down the steps for using this function.

User instructions

Step 1: prep work

Before getting started, double check and verify the following items are in order:

· Laser protective lens

· Nozzles

· Beam alignment

· Parameters

· Confirm your parameter input to the system.

Step 2: graphics selection

Leveraging parameters entered in Step 1, select a similar shape from the Bodor Laser Cutting Process Database to begin your cutting process.

Step 3: part adjustment and vectoring

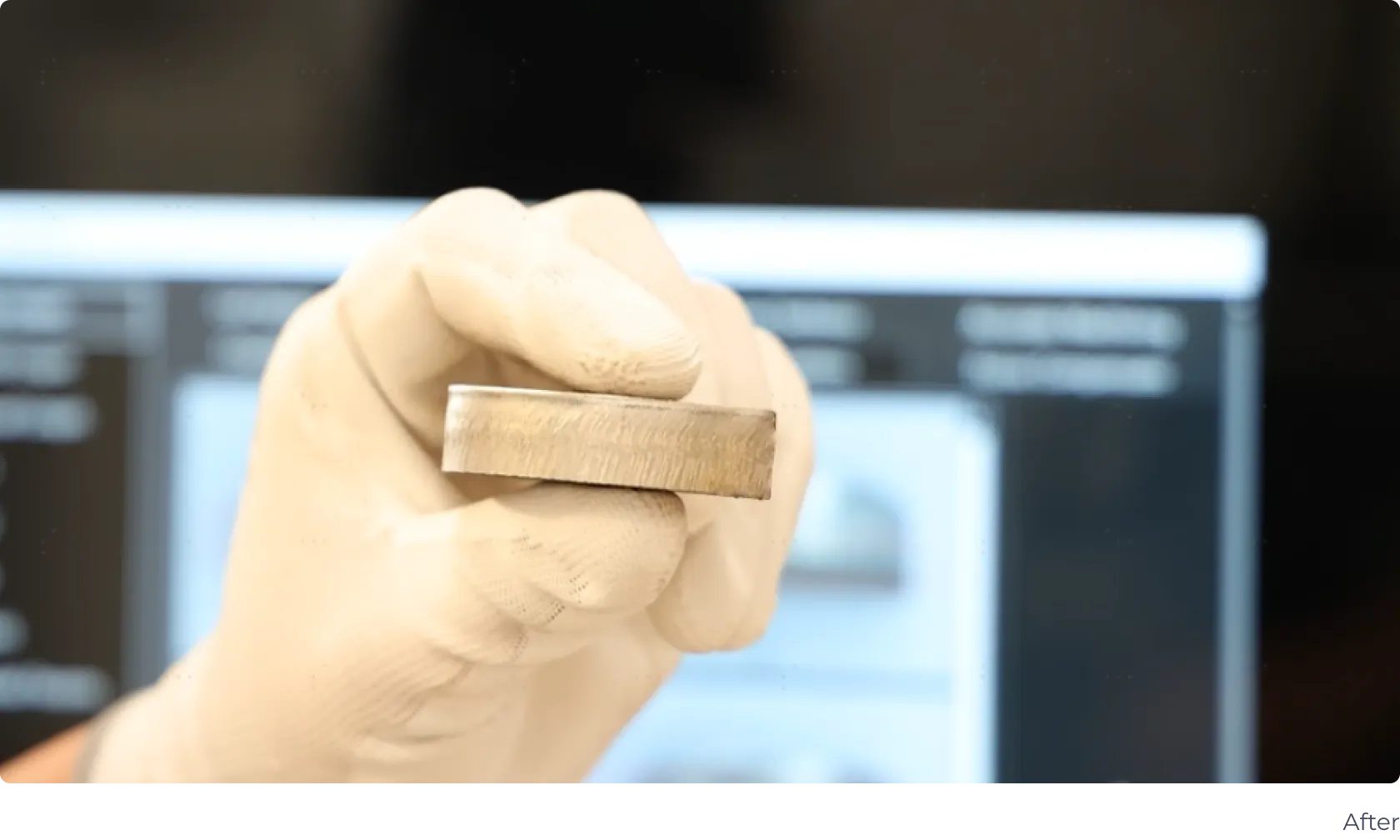

Compare your cutting sample with pictures within the database. Further examine and adjust your desired cutting parameters by clicking on the parts.

Step 4: store your customized cutting process

Once you are satisfied with the cutting sample, save the parameter input for future operations.

Bodor: the expert in intelligent laser cutting application

BodorThinker, along with the new AutoMatch function, has now been integrated into all Bodor 10kW+ laser cutting machines, meeting the market demand the right way, at the right time. Now our laser purchases are backed by the 5-year warranty , ensuring the machine continues to excel in perfect cuts for the years to come. Reach out to us, get a quote, and access everything you require for laser cutting in one place!