Bodor Tech Blog

Trending and helpful laser knowledge for your success

Revolutionize Construction Machinery Manufacturing with Laser Cutting Solutions

Construction equipment establishes the foundation of global infrastructure development, fulfilling project requirements of all sizes. From crawlers and towering cranes to excavators, loaders, and compactors, these diverse machines facilitate efficient execution of tasks like earthmoving, material handling, concrete placement, road construction, and demolition.

Laser technology benefits

Historical reasons have left the industry with a large inventory of outdated metal cutting equipment. Traditional manufacturing techniques, such as plasma, flame, and CO2 cutting, are hindering progress due to slower processing speeds, lower efficiency, and inferior quality. Significant technological advancements in the construction machinery manufacturing industry have led to the development of smarter, more efficient, and environmentally friendly machinery at metal workshops and facilities.

Laser cutting technology has revolutionized the production line of construction equipment, making it one of the most advanced approaches within the industrial sector. In comparison to traditional processing methods, its precision, versatility, and efficiency changed the fabrication of components and parts, thus enhancing performance, durability, and productivity.

Laser application in construction machinery manufacturing

Lasers utilize a precise, high-density beam for scanning and tracking. This non-contact processing method eliminates the risks of damage to the surface, producing clean and straight cuts with minimal taper and heat deformation. Besides the quality presented, lasers are able to cut faster for much lower operating costs. They are an environmentally conscious choice as they generate no harmful particles or gases.

Laser cutting is crucial in fabricating key components for excavators, loaders, and support plates.

·Excavators - It enables manufacturers to achieve intricate shapes and precise tolerances for excavator parts like engine components, boom arms, and buckets, ensuring durability and efficiency.

·Loaders - For loaders, laser cutting produces highly durable and accurate components, including buckets, arms, and chassis parts, with superior weldability and structural integrity.

·Support plates - Laser cutting is extensively used for support plates and structural elements, creating precise hole patterns, slots, and contours that enhance the integration and performance of hydraulic systems, engine mounts, and chassis frameworks.

Bodor: a reliable solution provider for construction equipment parts

When fabricating heavy equipment components, operational efficiency and precision are crucial. Complemented by automation devices, Bodor offers a range of laser cutting solutions that prioritize both production quality and precision for large-scale processing.

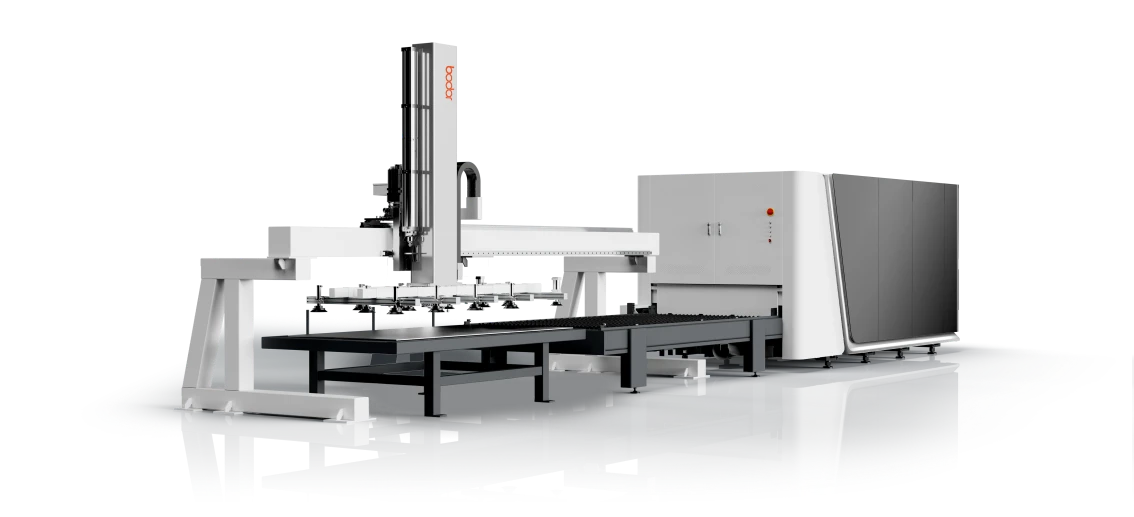

For sheet metal cutting, Bodor P series is an excellent choice that ensures steady performance with high efficiency.

(Bodor P6)

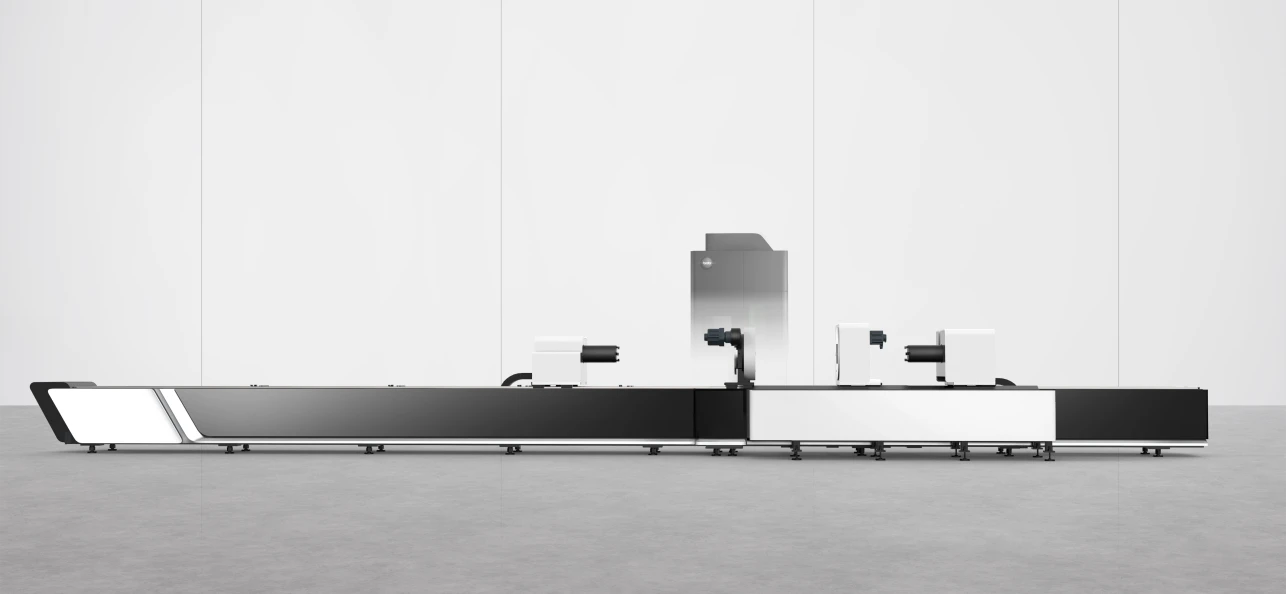

For tube processing, discover Bodor M series laser cutting machine along with its intelligent features. Equipped with 4 chucks, this high-end product produces top-notch cuts and utilizes every piece of material to the largest extent possible.

(Bodor M2, 4 chucks)

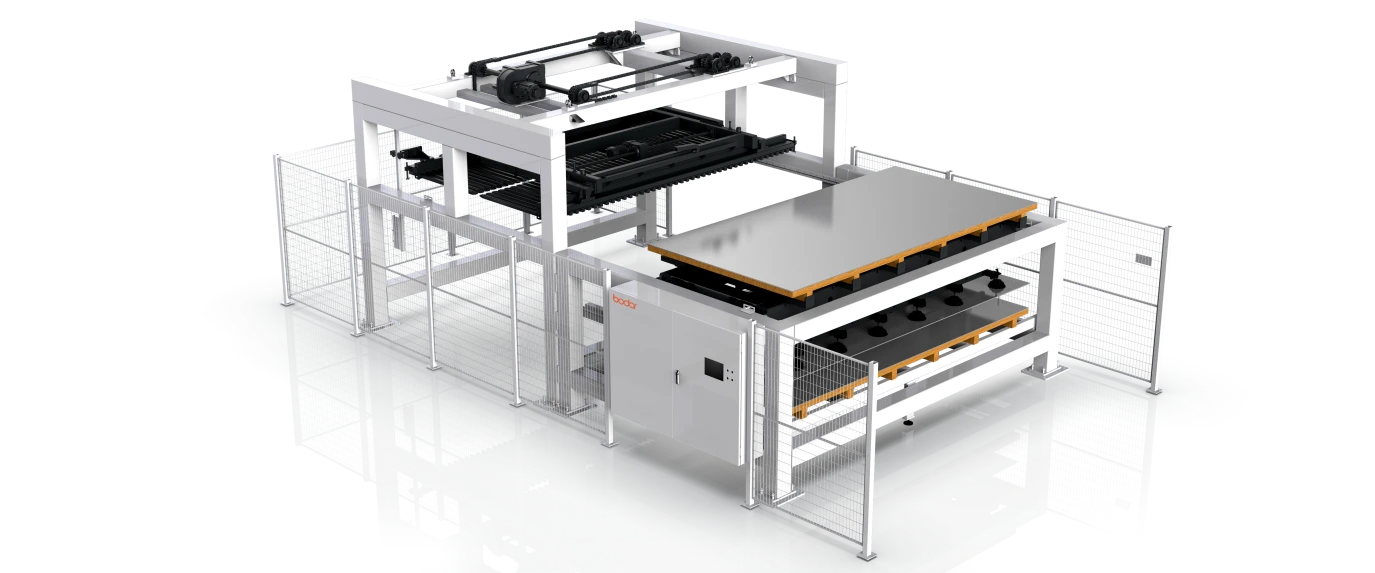

With a high-strength linear structure, the iLoader automatic loading module offers provides greater rigidity and loading capacity, accommodating sheets up to 20mm thick. With flexible loading size options, iLoader can handle various sizes and types of sheets.

(iLoader, automatic loading module for sheet metal laser)

Completing the process in 110 seconds, iTrans is a fully automated device for tube loading and unloading operation. With a flexible layout, this module can be positioned on either the left or right, adapting to various on-site requirements.

(iTrans, automatic loading and unloading system for tube laser)

If you are interested in any of Bodor’s laser machines for construction equipment manufacturing, please contact us or download our construction equipment whitepaper.