Bodor Tech Blog

Trending and helpful laser knowledge for your success

Stainless Steel Kitchen Equipment: Laser Manufacturing Solutions in the Food Service Industry

Known for its strength, durability, and hygienic properties, stainless steel has become a premium material for manufacturing kitchen equipment. In the kitchen environment, cabinets and kitchenware made of stainless steel easily withstand daily use, heat, and humidity without warping or deteriorating.

Whether it’s cabinets with a metal frame or entirely metallic appliances, the production depends on extensive manufacturing solutions for stainless steel.

High-quality standards are essential for the surfaces of kitchen equipment. Mirror-finish stainless steel and brushed stainless steel are usually supplied as film-laminated sheets. In this case, the manufacturing processes need to guarantee the cleanliness of the surfaces in order to uphold component quality. This requires a cutting method able to process with the protective film.

However, traditional stainless steel processing methods such as CO2 cutting often fall short in achieving the desired quality or surface cleanliness. Also, with a relatively low photoelectric conversion efficiency, CO2 cutting consumes auxiliary gases that lead to significant increases in everyday operation costs.

Laser cutting benefits

In comparison to CO2 laser cutting, fiber laser technology is a more suitable option for stainless steel kitchen equipment fabrication.

Thanks to its simple optical path, a fiber cutting system does not require demanding standards for the external environment and can handle dust, vibration, humidity, and temperature well. Its high durability indicates low maintenance investments. Surface conditions are also maintained during fiber laser cutting, eliminating the need for auxiliary gas consumption and further reducing operating costs.

Over the years, fiber laser welding has emerged as a highly popular technique when it comes to stainless steel manufacturing. It is able to efficiently weld steel sheet joints, finishing complete fusion of the seam without leaving any gaps. With a low learning curve, the operation for handheld laser welding is simple. Handheld laser welders can facilitate continuous 24-hour laser processing, significantly improving the efficiency of subsequent tasks.

Specific laser application in the industry

Customizing commercial kitchen equipment and culinary products to suit clients’ specific kitchen environments is common practice. Therefore, laser technology is especially applicable for the manufacturing of metal sheet and tube components.

In general, lasers with 6kW or lower power are sufficient for most manufacturing needs related to stainless steel kitchen cabinets and kitchenware.

Lasers with 6kW power are ideal for panel and door processing, as they produce high-quality finishes and precise measurements for cabinet doors, drawer fronts, and back panels. Moreover, laser cutting is effective for creating support brackets and frames, ensuring structures capable of supporting the weight of cabinet parts.

In addition to larger components, laser technology is primarily used to create decorative elements such as trim strips, handles, and knobs. Its precise cutting capabilities enable the fabrication of intricate shapes and designs, making it an excellent choice for the production of decorative metal parts.

Bodor solutions for stainless steel kitchen equipment

High-powered laser cutting systems are typically unnecessary for the manufacturing of stainless steel cabinets and kitchenware, but investing in versatile and automated systems is recommended.

Bodor’s fiber laser cutting machines are equipped with industry-specific features for processing stainless steel.

Film cutting - Bodor equipment can efficiently process film-coated stainless steel sheets, ensuring the sheets remain clean without the need for film removal.

Bend line marking - Bodor equipment enables precise identification of areas that require bending, streamlining bending procedures and enhancing workflow efficiency.

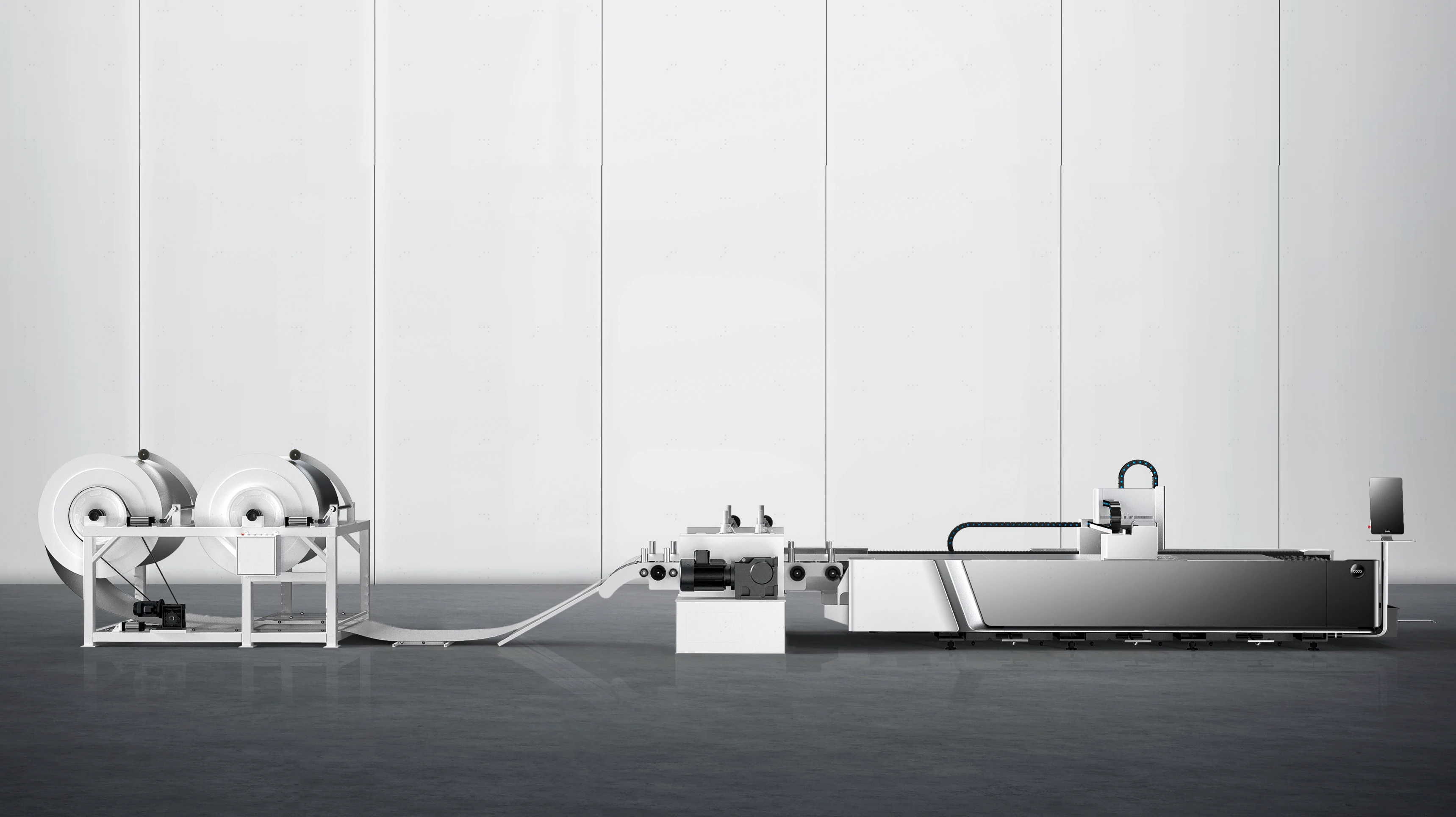

The Bodor R series is a well-suited solution, as it is able to achieve the highest productivity in processing sheet and coil materials. The R series production line integrates all the necessary operations for coil materials, including uncoiling, leveling, nesting, and cutting. It effortlessly carries out all stainless steel procedures in a single set.

In terms of laser welding solutions, the Pro 1500 is a great product for the stainless steel kitchen equipment fabrication. With self-cooling features, this handheld laser welding machine provides maximum flexibility for the following welding procedures. Due to its efficiency and versatility, the portable design further facilitates customization in stainless steel kitchen cabinet structures.

If you are interested in Bodor’s products, please contact us. Whether you are looking to enhance precision and productivity in stainless steel cabinet or kitchenware manufacturing, our team is available to present you detailed information.